Customizable Shopping Bag Solutions for Retailers

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

Polymer extrusion technology is a critical process in the manufacturing of plastic products, enabling the transformation of raw polymer materials into usable forms. This comprehensive guide will delve into the core principles of polymer extrusion, the key components of extruder machines, and the various processes involved. Readers will gain insights into how mechanical and thermal principles govern the extrusion process, the significance of different extruder components, and the applications of various extrusion techniques. Understanding these fundamentals is essential for optimizing production efficiency and product quality in the plastic manufacturing industry. This article will also explore how Kingdom Machine Co., Ltd. applies these principles in their machinery, offering innovative solutions for modern extrusion needs.

Plastic extrusion is governed by several core principles that dictate how polymers are processed into final products. Understanding these principles is crucial for anyone involved in the plastic manufacturing industry, as they directly impact the quality and efficiency of the extrusion process.

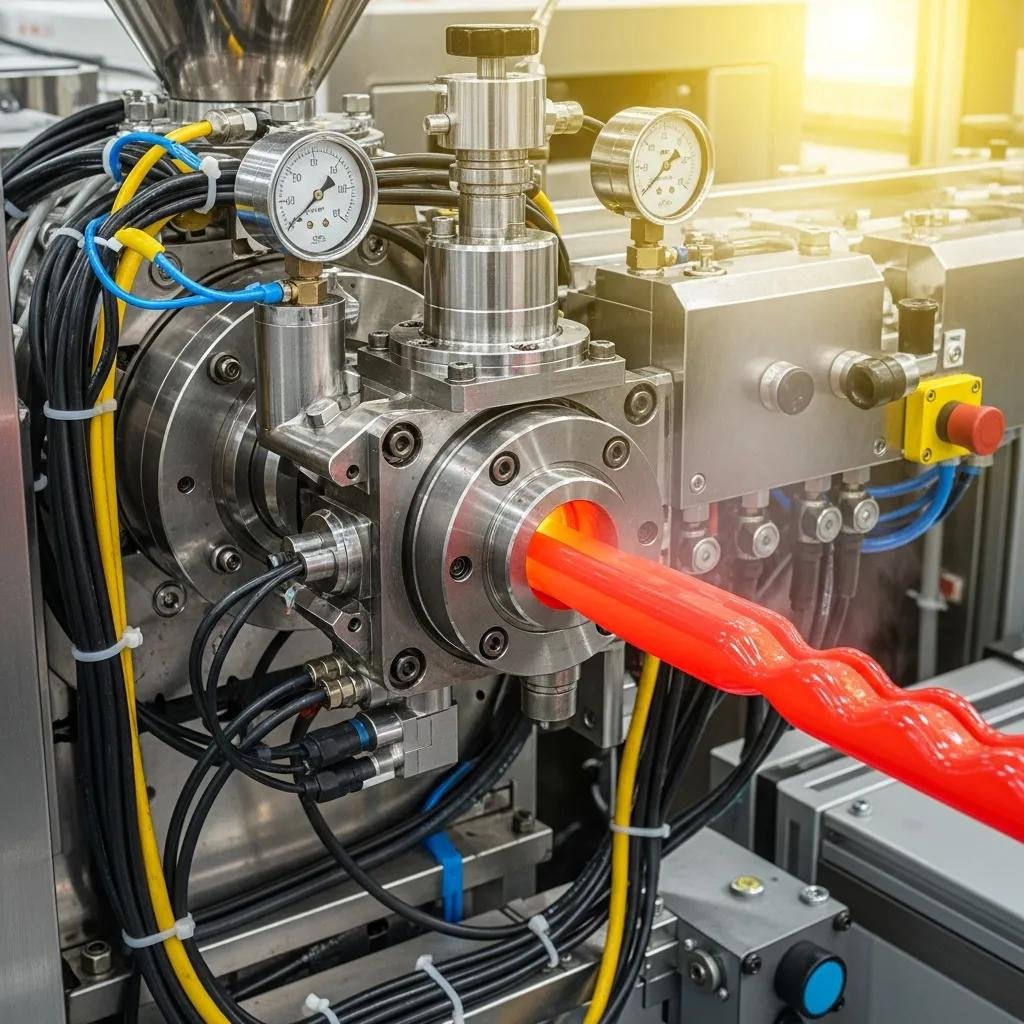

Mechanical principles play a vital role in the extrusion process, primarily through the design and function of the extruder screw. The extruder screw is responsible for conveying, melting, and mixing the polymer material. It generates shear force, which is essential for melting the polymer and ensuring a homogeneous melt. Additionally, pressure control within the extruder is critical, as it influences the flow rate and quality of the extrudate. Properly designed mechanical components ensure efficient material processing and optimal product characteristics.

Thermal principles are equally important in the extrusion process, particularly in the melting and homogenization of polymers. The extruder utilizes heating zones to raise the temperature of the polymer to its melting point, allowing it to flow smoothly through the die. Temperature control is crucial, as it affects the viscosity of the melt and the overall quality of the final product. Homogenization ensures that the polymer is uniformly melted, which is essential for achieving consistent product properties.

An extruder machine consists of several key components, each playing a specific role in the extrusion process. Understanding these components is essential for optimizing machine performance and product quality.

The hopper and feeding zone are critical for the initial stages of the extrusion process. The hopper serves as the entry point for raw polymer materials, where they are gravity-fed into the extruder. The feeding zone is designed to ensure a consistent flow of material into the screw, which is vital for maintaining a steady extrusion rate. Different feeding mechanisms, such as gravity feed and starve feeding, can significantly impact extrusion efficiency and product quality.

The extruder barrel houses the screw and is equipped with heating zones that facilitate the melting of the polymer. Each heating zone is carefully controlled to achieve the desired temperature profile, which is essential for effective melting and processing. Heat transfer methods, such as conduction and convection, are employed to ensure uniform heating throughout the barrel. Proper temperature control is crucial for maintaining the viscosity of the melt and achieving optimal flow characteristics.

The design of the extruder screw significantly influences the flow characteristics of the polymer melt. Different screw designs, such as single-screw and twin-screw configurations, offer distinct advantages depending on the application. For instance, twin-screw extruders provide better mixing and dispersion of additives, while single-screw extruders are often more efficient for simple polymer processing. The geometry of the screw, including its pitch and depth, also affects the flow rate and pressure within the extruder.

Extrusion dies are essential components that shape the molten polymer into the desired final product. Various types of dies are used in the extrusion process, including flat dies for sheet production and circular dies for pipe and film applications. The design of the die directly impacts the flow of the polymer and the final product’s dimensions and properties. Understanding the specific applications of different dies is crucial for selecting the right equipment for a given production process.

Polymer extrusion encompasses several major processes, each with unique applications in the plastic manufacturing industry. Understanding these processes is essential for selecting the appropriate method for specific product requirements.

Blown film extrusion is a widely used process for producing thin plastic films. In this process, molten polymer is extruded through a circular die and then inflated to form a bubble. The film is then cooled and flattened for further processing. This method is commonly used in packaging applications, as it produces lightweight, flexible films that can be used for bags, wraps, and other packaging materials. The benefits of blown film extrusion include high production rates and the ability to create multi-layer films for enhanced barrier properties.

Sheet and profile extrusion processes are distinct methods used to produce different types of plastic products. Sheet extrusion involves the production of flat sheets, which can be further processed into various products, such as containers and displays. In contrast, profile extrusion is used to create specific shapes, such as pipes, tubing, and window frames. The key differences between these processes lie in the die design and the cooling methods employed, which affect the final product’s dimensions and properties.

Co-extrusion technology allows for the simultaneous extrusion of multiple layers of different materials. This process is particularly beneficial for producing products with enhanced properties, such as improved barrier performance or aesthetic appeal. Co-extrusion is commonly used in applications like food packaging, where multiple layers can provide protection against moisture and oxygen. The ability to combine different materials in a single product offers manufacturers greater flexibility in design and functionality.

The choice of polymer materials is crucial in the extrusion process, as it directly impacts the properties and performance of the final product. Understanding the characteristics of commonly used materials is essential for optimizing extrusion outcomes.

Common thermoplastics used in extrusion include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). Each of these materials possesses unique properties that make them suitable for specific applications. For instance, PE is known for its excellent chemical resistance and flexibility, PP offers higher temperature resistance and rigidity, and PVC is valued for its durability and flame resistance. Understanding these properties helps manufacturers select the appropriate material for their specific extrusion needs.

Additives and compounding play a significant role in enhancing the performance of polymers during the extrusion process. Various additives, such as stabilizers, colorants, and fillers, can be incorporated into the polymer matrix to improve its properties. For example, UV stabilizers can enhance the material’s resistance to degradation from sunlight, while fillers can improve mechanical strength and reduce production costs. Compounding allows for the customization of polymer formulations to meet specific performance requirements.

Optimizing the extrusion process is essential for achieving high-quality products and efficient production. Understanding the key parameters that affect extrusion quality is crucial for troubleshooting common issues.

Several key process parameters influence the quality of the extruded product, including temperature, pressure, and screw speed. Maintaining optimal temperature control is critical for achieving the desired melt viscosity and flow characteristics. Pressure settings must also be carefully monitored to ensure consistent material flow through the die. Additionally, screw speed affects the residence time of the polymer in the extruder, which can impact the degree of mixing and homogenization.

Common extrusion issues, such as melt fracture, die swell, and inconsistent product dimensions, can significantly affect production efficiency and product quality. Identifying the root causes of these issues is essential for effective troubleshooting. For instance, melt fracture may occur due to excessive shear rates or improper temperature settings, while die swell can result from the viscoelastic nature of the polymer melt and the relaxation of stresses after exiting the die. Implementing systematic troubleshooting strategies can help manufacturers resolve these issues and optimize their extrusion processes.

Kingdom Machine Co., Ltd. leverages the fundamental principles of polymer extrusion in the design and manufacturing of their machinery. Their expertise in this field allows them to provide innovative solutions tailored to the needs of their clients.

Kingdom Machine’s blown film extrusion machines are designed to embody the core principles of polymer extrusion, ensuring efficient processing and high-quality output. These machines feature advanced screw designs that optimize melting and mixing, along with precise temperature control systems that maintain consistent melt quality. The integration of these principles results in superior film properties and enhanced production efficiency.

In addition to standard machinery, Kingdom Machine offers custom extrusion solutions tailored to specific client requirements. These solutions may include specialized screw designs, unique die configurations, and advanced control systems that enhance production capabilities. By understanding the unique needs of their clients, Kingdom Machine can provide tailored solutions that improve product quality and operational efficiency.

Sustainability and automation are increasingly important in modern extrusion technology. Kingdom Machine is committed to integrating sustainable practices into their machinery, such as energy-efficient designs and the use of recyclable materials. Additionally, automation technologies are employed to enhance production efficiency and reduce labor costs. By embracing these trends, Kingdom Machine ensures that their extrusion solutions meet the demands of a rapidly evolving industry.

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

Learn about effective plastic recycling strategies implemented across Europe. Join the movement towards sustainability and reduce environmental impact today.

Learn how to effectively launch a high-volume bag production facility with our detailed case study. Optimize operations and maximize returns today!

Elevate your food safety with innovative plastic packaging. Our food-grade bags and films enhance freshness, ensuring quality and longevity in every bite.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;