Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Blown film extrusion is a critical process in the production of plastic films, widely used in packaging and other applications. However, manufacturers often encounter various challenges that can affect the quality of the final product. This guide aims to explore common issues faced during blown film extrusion, providing insights into troubleshooting and optimization strategies. Readers will learn about frequent defects, their causes, and effective solutions to enhance film quality. The article will cover topics such as bubble instability, gauge variation, melt fracture, and the role of Kingdom Machine Co., Ltd. in addressing these challenges with their advanced equipment. By understanding these issues and their solutions, manufacturers can improve production efficiency and product quality.

Blown film extrusion can lead to several defects that compromise film quality. Understanding these defects is essential for effective troubleshooting and optimization. Common defects include bubble instability, gauge variation, and surface imperfections, each of which can significantly impact the performance of the final product.

Bubble instability occurs when the film bubble fluctuates in size or shape during the extrusion process. This instability can lead to uneven thickness and weak spots in the film, ultimately affecting its mechanical properties and barrier performance. Factors contributing to bubble instability include improper cooling rates, inconsistent melt temperature, and fluctuations in air pressure. Addressing these factors is crucial for maintaining film quality and consistency.

Gauge variation refers to the inconsistency in film thickness, which can result from several factors during the extrusion process. Common causes include variations in melt flow rate, die design, and cooling conditions. Gauge variation can lead to increased material waste and reduced product performance. Implementing precise control measures, such as optimizing die design and maintaining consistent processing conditions, can help mitigate this issue.

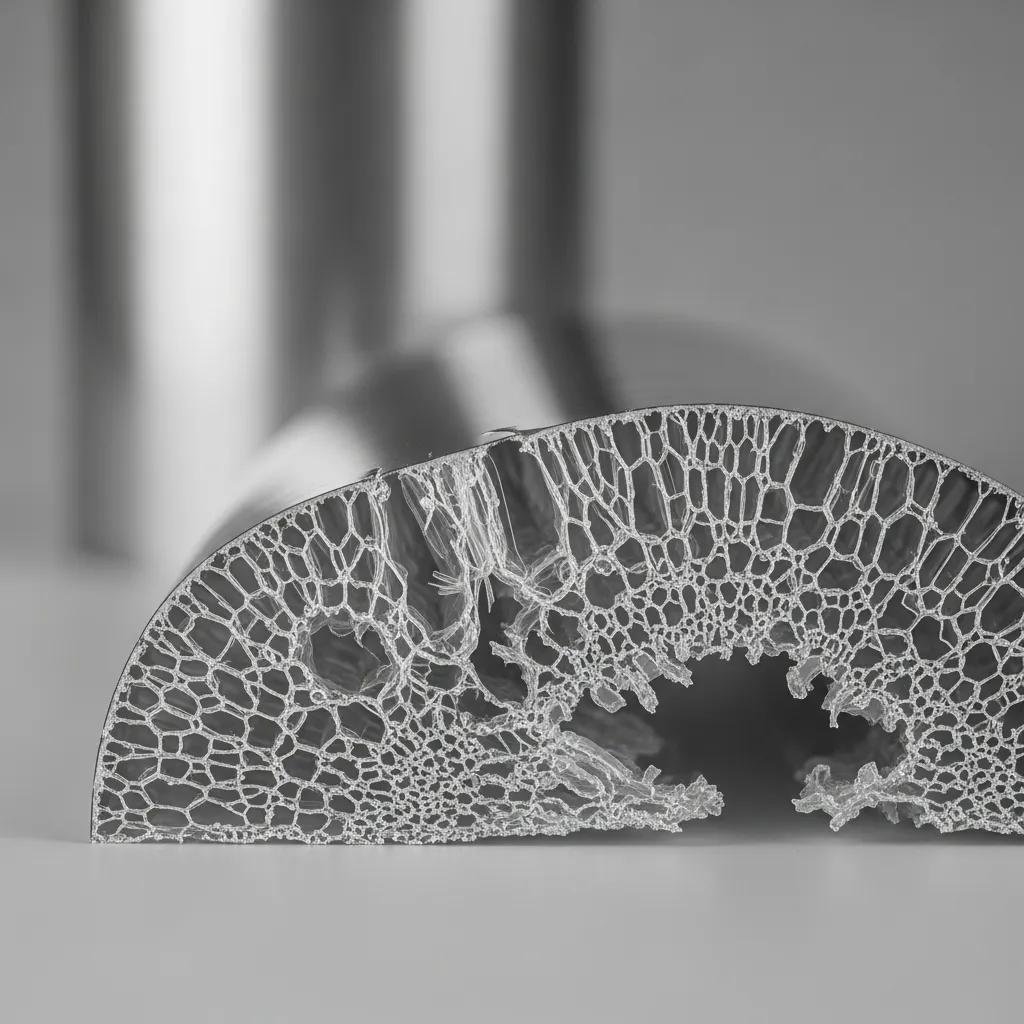

Melt fracture and surface defects are significant concerns in blown film extrusion, as they can affect the aesthetic and functional properties of the film. Understanding the causes and preventive measures is essential for manufacturers aiming to enhance product quality.

Melt fracture occurs when the polymer melt experiences excessive shear stress, leading to surface roughness and defects. Common causes include high shear rates, inappropriate die design, and excessive drawdown rates. These factors can result in a rough film surface, which may affect printability and sealability. Identifying and controlling these variables is vital for producing high-quality films.

To reduce the risks of melt fracture, manufacturers can implement several process adjustments. Key strategies include optimizing the die design to minimize shear stress, adjusting the melt temperature to ensure proper flow characteristics, and controlling the drawdown rate to prevent excessive stretching. By making these adjustments, manufacturers can significantly improve film quality and reduce the occurrence of melt fracture.

Wrinkles, creases, and film stickiness are common issues that can arise during the blown film extrusion process. These defects can lead to production inefficiencies and affect the usability of the final product.

Cooling and winder settings play a crucial role in the formation of wrinkles and creases in blown film. Inadequate cooling can cause the film to retain heat, leading to dimensional instability and wrinkles. Properly adjusting cooling rates and ensuring consistent winder tension can help minimize these issues. Manufacturers should regularly monitor these settings to maintain optimal film quality.

Film blocking and stickiness can occur when films adhere to each other during storage or processing. Effective methods to prevent these issues include using anti-block additives in the resin formulation, optimizing the cooling process, and ensuring proper winding techniques. By implementing these strategies, manufacturers can enhance the performance and usability of their films.

Extruder machine problems can significantly impact film production efficiency and quality. Identifying and addressing these issues is essential for maintaining optimal performance.

Signs of extruder motor overload include unusual noises, increased energy consumption, and inconsistent output. Additionally, screw wear can manifest as reduced output and increased melt temperature. Regular maintenance and monitoring of these parameters are crucial for preventing significant production disruptions.

Temperature and pressure control are critical factors in extruder performance. Inconsistent temperature can lead to poor melt quality, while improper pressure settings can affect the flow rate and film thickness. Implementing precise control systems for temperature and pressure can enhance extruder performance and improve film quality.

Optimizing material and process parameters is essential for achieving high-quality blown films. Understanding the interplay between these factors can lead to significant improvements in film performance.

The choice of resin plays a vital role in film quality. Different resins exhibit varying properties, such as melt flow rate and thermal stability, which can influence the extrusion process. Selecting the appropriate resin for specific applications can help minimize defects and enhance film performance.

The blow-up ratio and cooling rate are critical parameters that affect film uniformity. A higher blow-up ratio can lead to thinner films, while inadequate cooling can result in uneven thickness. Balancing these parameters is essential for producing uniform films with consistent properties.

Kingdom Machine Co., Ltd. specializes in providing advanced blown film extrusion equipment designed to address common production challenges. Their machinery incorporates innovative features that enhance stability and efficiency.

Kingdom Machine’s blown film machines are equipped with advanced control systems that ensure consistent temperature and pressure throughout the extrusion process. Additionally, their die designs are optimized to minimize shear stress, reducing the risk of melt fracture and improving film quality. These features contribute to enhanced stability and overall production efficiency.

Kingdom Machine Co., Ltd. offers comprehensive after-sales service to support troubleshooting and maintenance. Their team of experts provides guidance on optimizing machine performance and addressing any operational issues that may arise. This support is crucial for manufacturers seeking to maintain high production standards and minimize downtime.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;

film blown machine, blown film extrusion, plastic bag making machine

At Kingdom Machinery Co., Ltd., we specialize in providing high-quality machinery tailored for the plastic bag and blown film manufacturing industries. Our commitment to excellence ensures that our clients receive reliable and efficient equipment that meets their specific production needs.

With years of experience in the industry, we understand the challenges faced by manufacturers. That's why we offer a range of machines designed to enhance productivity while maintaining top-notch quality. From automatic T-shirt bag making machines to advanced blown film machines, our products are engineered to deliver superior performance and durability.

Our commitment to innovation sets us apart in the plastic machinery industry. We continuously invest in research and development to integrate the latest technology into our machines, ensuring they operate at peak efficiency and produce high-quality products.

For instance, our advanced film blowing machines utilize cutting-edge technology to optimize the extrusion process, resulting in consistent film thickness and excellent tensile strength. This not only enhances the quality of the finished product but also reduces material waste, making our machines an eco-friendly choice for manufacturers.

At Kingdom Machinery, we prioritize our customers' needs and satisfaction. Our dedicated support team is available to assist clients throughout the entire process, from selecting the right machinery to providing after-sales service and maintenance.

We believe that strong customer relationships are built on trust and reliability. That's why we offer flexible customization options for our machines, ensuring they fit seamlessly into our clients' production lines. Our timely after-sales service further reinforces our commitment to providing exceptional support.

As a leading manufacturer of plastic bag machinery, we recognize the importance of environmental sustainability. Our machines are designed to minimize energy consumption and reduce waste, aligning with global efforts to promote eco-friendly manufacturing practices.

We also offer a range of recycling machines that facilitate the processing of plastic waste into reusable materials, helping businesses contribute to a circular economy. By choosing our machinery, clients not only improve their production efficiency but also play a vital role in protecting the environment.