Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Polypropylene blown film extrusion is a manufacturing process that converts polypropylene resin into thin, flexible films used across packaging, agriculture, and industrial applications. This guide explains how PP film is produced, why polypropylene is favored for many film applications, and how Emiratis manufacturers can match machine types and technical specifications to their product goals. Many businesses face choices about capacity, material compatibility, and after-sales support when investing in a PP extrusion machine; this article provides practical criteria, component-level details, and decision tools to reduce risk. You will find clear explanations of machine categories (single-layer, multi-layer, high-speed, biodegradable-capable), step-by-step process notes, EAV comparison tables, and a buyer-oriented checklist tailored to United Arab Emirates’s market conditions. Finally, a supplier-focused section summarizes how China Evergreen Machinery Co., Ltd. (operating as Kingdom Machinery) supports Emiratis customers with delivery, customization, quality control, and after-sales services.

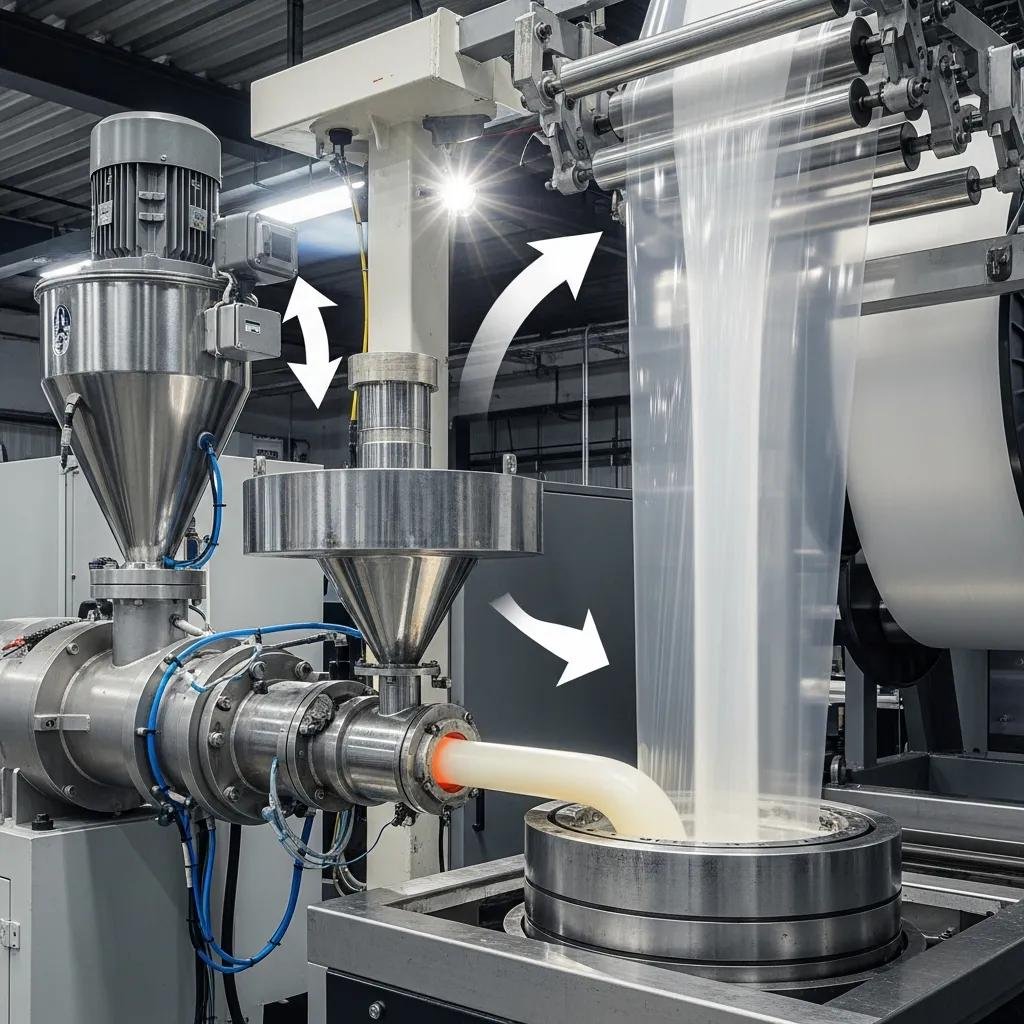

Polypropylene blown film extrusion is a process that melts polypropylene resin, forces the melt through a circular die, and inflates a thin tubular bubble that cools and is collapsed into film, producing strong, heat-resistant sheets for packaging and industrial use. The mechanism—extrusion, bubble formation, air-ring cooling, and winding—yields films with balanced mechanical properties and clarity, making polypropylene ideal where stiffness, heat resistance, and printable surface are required. PP blown film is essential for Emiratis manufacturers because it supports high-throughput PP film manufacturing for sacks, garment bags, and food-contact films while enabling cost-effective material use and consistent product quality. Below are three core benefits that summarize why PP film is widely adopted.

Primary benefits of PP blown film:

These performance traits lead directly into a practical, stepwise look at how the PP blown film extrusion process works and where processing controls affect quality.

The PP blown film extrusion process follows a defined sequence of steps that transform resin pellets into finished film. First, polypropylene pellets are fed into the extruder hopper where the screw conveys and melts the polymer under controlled temperature zones; this melting and homogenization step ensures consistent melt quality. Next, the molten PP passes through a die head that shapes flow into a circular annulus; air is introduced through the die to form a bubble that expands to the target layflat width while the air ring controls bubble cooling and stability. After the bubble has solidified to the required film properties, nip rollers collapse and guide the film to winding units where tension control and winding speed determine roll quality. Monitoring melt pressure, bubble position, and thickness feedback are common troubleshooting points to maintain consistent output and film uniformity.

Polypropylene offers a combination of mechanical, thermal, and barrier properties that make it favorable for a range of blown film applications compared with PE alternatives. Mechanically, PP films show higher modulus and tensile strength, which improves puncture resistance in industrial packaging and reduces sag in vertical form-fill-seal applications. Thermally, PP tolerates higher sealing temperatures and provides better hot tack for high-speed bag-making, supporting faster lines and more robust seals. From a material lifecycle perspective, PP can be recycled in many streams and can be formulated with biodegradable additives when needed, allowing manufacturers to balance performance with environmental objectives. Understanding these advantages helps buyers choose machine features that preserve PP’s strengths during processing, which leads into comparing available machine types.

PP blown film machines available to Emiratis manufacturers include single-layer extruders, multi-layer co-extrusion lines, high-speed production lines, and lines engineered for biodegradable or specialty resins. Each category addresses different production goals: single-layer lines are simpler and cost-effective for basic bags, multi-layer lines enable barrier or functional layers, high-speed lines maximize throughput for large-volume PP film manufacturing, and biodegradable-capable lines accept specialty resins with modified processing windows. Below is a concise EAV-style comparison to help match machine architecture to intended applications and output ranges.

Introductory comparison table of common PP blown film machine types and typical attributes:

| Machine Type | Key Attributes | Typical Output / Application |

|---|---|---|

| Single-layer PP extruder | Simple screw/barrel, single die, lower automation | Moderate output (50–250 kg/hr); basic bags, liners |

| Multi-layer PP co-extrusion line | Multiple extruders, feedblock or multilayer die | 100–600 kg/hr; barrier films, printed film, lamination |

| High-speed PP blown film machine | Reinforced screws, high-power motors, advanced cooling | >300 kg/hr; mass packaging, automated bag lines |

| Biodegradable-capable PP line | Temperature control, specialized screws, feed systems | Variable output; biodegradable blends, niche markets |

This comparison clarifies selection trade-offs and leads into the functional differences between single-layer and multi-layer machines and high-speed versus biodegradable-capable systems.

Single-layer PP blown film extruders consist of one extruder feeding a single die, which simplifies operation and maintenance while producing films suitable for many basic packaging tasks. The mechanism is straightforward: one screw heats and mixes the resin and the single die forms the bubble; this simplicity keeps capital and operating costs lower and makes troubleshooting more direct. Multi-layer systems, by contrast, combine two or more extruders through a feedblock or multi-manifold die to co-extrude layers with distinct functions—such as a tough core, a printable skin, or a barrier layer—resulting in films that meet more demanding performance specifications. While multi-layer lines increase equipment cost and require more precise synchronization and layer weight control, they enable value-added products such as metallizable films, printed lamination substrates, and improved barrier performance for food packaging.

High-speed PP blown film machines prioritize throughput and mechanical robustness, using reinforced screws with higher L/D ratios, more powerful motors, and advanced winding and cooling systems to maintain bubble stability at elevated line speeds. The engineering trade-offs include tighter tolerances, stronger drive systems, and more sophisticated automatic thickness control to avoid film defects while maximizing kg/hr output. Machines designed for biodegradable or specialty PP blends require adaptable thermal profiles, specialized screw geometries to handle different melt viscosities, and controlled cooling strategies to prevent premature crystallization or film brittleness. These biodegradable-capable lines often need slower, more controlled processing windows than high-speed PP lines, so buyers must weigh throughput against material compatibility and end-use sustainability goals.

Introductory note: the EAV comparison above provides a snapshot to help select machines; the following decision criteria section helps transform these technical comparisons into practical purchasing choices for Emiratis businesses.

| Decision Factor | Metric | Recommended Expectation |

|---|---|---|

| Capacity | kg/hr | Match market demand with 20–30% growth margin |

| Automation level | PLC features | Basic PLC for single-layer; advanced PID/ATC for high-speed lines |

| Warranty & QA | Warranty terms | Expect component warranties and factory final inspection |

| Lead time | Days | Standard machines typically deliver in weeks, not months |

Choosing the right polypropylene film extruder begins by defining product mix, target throughput, and quality requirements, then mapping those needs to machine topology, screw/die technology, and control systems. The mechanism to evaluate value involves balancing upfront cost, expected kg/hr, energy consumption, and the availability of local support and spare parts, which directly affect total cost of ownership. Emiratis buyers should prioritize machines that accommodate intended PP grades and any biodegradable formulations they plan to use, while ensuring the control features support stable bubble formation at the desired speeds. The following checklist and decision matrix present actionable buyer criteria and thresholds to use when comparing suppliers and models.

Checklist for buyers before requesting quotes:

Summary: Using this checklist helps narrow vendor options and prepares technical questions for suppliers, especially about delivery timelines and warranty coverage.

Price drivers for a PP blown film extruder include the number and quality of extruders in a line, the sophistication of the control system, the die and air-ring design, and the level of automation for winding and thickness control. High-precision screws with tailored mixing sections and higher L/D ratios typically raise costs but improve melt homogeneity and film uniformity, offering better value over time through reduced scrap. Co-extrusion capability and specialized die heads add manufacturing flexibility but require more complex spare parts and maintenance, which should be factored into lifetime cost. Buyers must evaluate not just purchase price but expected uptime, local serviceability, and the supplier’s QA standards to determine the true value of a PP extrusion machine.

After-sales service and local support reduce downtime and total cost of ownership by ensuring timely spare parts, on-site troubleshooting, and operator training; these services are especially critical where supply chains are long. Practical assessment criteria include supplier response time for fault diagnosis, availability of common spare parts in the region, and whether the supplier provides installation, commissioning, and process training as part of the purchase package. A supplier with local experience in United Arab Emirates or a partner network in cities such as Lagos, Kano, or Ibadan can often shorten lead times for spare parts and technical visits. Evaluating service-level expectations upfront ensures that the chosen polypropylene extruder machine remains productive and cost-effective throughout its life.

Introductory decision matrix for buyer trade-offs:

| Buying Factor | Attribute | Value to Expect |

|---|---|---|

| Capacity | kg/hr | Scalable capacity with 20–30% growth margin |

| Price | USD range | Reflects number of extruders and automation |

| Support | Warranty months | Clear warranty and spare parts policy |

| Delivery | Days | Sample and bulk delivery timelines disclosed |

A PP blown film line is composed of several meronomic parts—extruder (screw and barrel), die head, air ring/cooling system, control panel (PLC), and winder/take-up units—each of which influences film properties and process stability. The extruder’s screw geometry, L/D ratio, and motor power determine shear, melting quality, and throughput, while the die head design governs melt distribution and concentricity, directly affecting thickness uniformity. The air ring and cooling strategy set bubble cooling rate, which controls crystallinity, clarity, and mechanical performance of polypropylene film. Finally, modern PLC-based control systems and automatic thickness control (ATC) loops manage process variables to maintain consistent film gauge and reduce scrap, which is essential for predictable PP film manufacturing.

Key components summarized in a technical EAV table:

| Component | Key Specification | Processing Impact |

|---|---|---|

| Extruder (screw & barrel) | Screw diameter, L/D ratio, screw profile | Melting efficiency, homogenization, throughput stability |

| Die head | Annular gap, concentricity, feedblock | Film uniformity, layer distribution in co-extrusion |

| Air ring / cooling | Air flow pattern, cooling rate | Bubble stability, clarity, mechanical properties |

| Winder / take-up | Tension control, drum type | Roll quality, edge trim, winding density |

Screw design and die head technology form a semantic triple: Screw geometry → Homogenizes melt → Uniform film properties. Screw compression ratio, mixing elements, and L/D ratio regulate melting, dispersion of additives, and shear history, which together determine film clarity and mechanical uniformity. Die head design—including mandrel alignment, lip gap consistency, and temperature control—affects how evenly the molten PP is distributed around the annulus; any eccentricity creates thickness variation and optical defects. Selecting the appropriate screw profile for polypropylene and pairing it with a precision die head is essential for producing consistent, high-quality PP blown film, and these choices directly influence downstream requirements for cooling and winding.

Cooling and process control systems are critical for stabilizing the bubble and achieving target film properties: Air rings with adjustable flow patterns control the cooling rate and bubble shape, while vacuum-assisted cooling or supplementary chillers are sometimes used for tight tolerance films. Control systems—PLC with PID loops and automatic thickness control—monitor melt pressure, bubble diameter, and film gauge sensors to adjust screw speed, air ring flow, and haul-off rate in real time. These controls form the feedback relationship: Sensors → Controller → Actuators, which keeps the process within a narrow operating window and minimizes scrap. Investing in robust cooling design and closed-loop control systems improves consistency and reduces operator intervention on PP film extrusion lines.

Before moving into application areas, consider immediate practical optimizations such as selecting appropriate screw L/D ratios and ensuring die concentricity during installation, which directly improve film output and process stability.

Polypropylene blown film machinery serves a range of industrial applications in United Arab Emirates, including food packaging, garment bags, agricultural films, and industrial wrapping. Each application imposes different property needs: food packaging demands heat resistance and food-contact-safe materials, garment packaging prioritizes clarity and printable surfaces, agricultural films need UV resistance and toughness, and industrial wraps require high tensile strength and puncture resistance. Market trends in United Arab Emirates show steady demand for flexible packaging and growth in retail-ready packaging, which favors PP film for its balance of performance and cost. Sustainability considerations are increasingly relevant, with biodegradable PP blends and recyclable mono-material structures gaining attention among manufacturers and brand owners.

List of common PP film applications in United Arab Emirates with example specifications:

This overview of uses leads into practical specifics for each sector and how biodegradable options fit into sustainable packaging strategies.

Main industrial uses of PP film in United Arab Emirates include packaging for food and consumer goods, garment and textile wraps, agricultural mulches and shade netting, and sacks for industrial commodities; each use favors particular film thickness, clarity, and mechanical properties. For example, garment bags often use thin, high-clarity PP film to showcase products, while agricultural films require thicker gauges and UV additives for longevity. In food packaging, PP’s heat resistance enables reliable sealing and compatibility with some hot-fill processes, supporting shelf-stable products. Understanding these application-driven specifications allows manufacturers to choose machine features—such as co-extrusion for barrier layers or higher-power extruders for thicker gauges—that deliver the required product performance.

Biodegradable PP film extrusion typically involves processing polypropylene blends with biodegradable additives or copolymers that modify crystallinity and degradation behavior; machines must accommodate altered melting points and melt viscosities through adaptable screw designs and precise temperature control. Processing biodegradable blends often requires more controlled cooling to avoid brittleness and may mandate slower line speeds for stable film formation, so manufacturers should evaluate whether their chosen PP extrusion machine supports these adjustments. Market drivers for biodegradable PP include brand sustainability commitments and regulatory pressures favoring compostable or partially degradable packaging; however, buyers must balance these benefits with processing complexity and potential cost premiums. This context helps manufacturers decide whether to invest in specialty lines or accept modified processes on standard equipment.

China Evergreen Machinery Co., Ltd. (operating as Kingdom Machinery) positions itself as a manufacturer and global supplier of plastic film and plastic bag production equipment with explicit focus on serving the Emiratis market. The company emphasizes simple operation, perfect performance, easy maintenance, and timely after-sales service as core value propositions for buyers. Its quality assurance claims include 100% final inspection, a defect-control rate of 1%–3%, and a two-year warranty on timer switches; the supplier also highlights strong R&D capabilities across product, structural, software, and circuit engineering disciplines. Kingdom Machinery offers one-stop services including customization of logos, labels, and packaging, as well as new product development support, and cites competitive pricing through large-scale production and trained workers.

The supplier’s logistical and support claims for Emiratis clients are specific and operationally relevant: they advertise fast delivery timelines with samples within three days and bulk deliveries of standard machines in 15–20 days, and they note global experience with installations across many countries. For Emiratis buyers, the company’s stated market focus includes service coverage or presence in cities such as Lagos, Kano, Ibadan, and Benin City, and they underscore offerings such as installation, training, and spare parts support to reduce downtime for local operations. Prospective purchasers should request a technical consultation or quote and verify warranty and inspection records as part of procurement due diligence.

Kingdom Machinery’s stated advantages for Emiratis manufacturers center on fast delivery, customization, and quality control measures that reduce procurement risk and accelerate production startup. The firm claims the ability to deliver samples within three days and standard machine bulk shipments in 15–20 days, which shortens project timelines compared with longer lead-time suppliers. Customization services—covering logos, labels, and packaging as well as new product development—help local manufacturers develop market-differentiated film products without sourcing multiple vendors. Quality assurance practices such as 100% final inspection and a low defect control range (1%–3%) are positioned to provide predictable equipment performance at installation and during warranty periods.

Competitive pricing, combined with quick delivery and timely after-sales service, delivers several practical benefits for Emiratis buyers: lower initial investment reduces capital barriers to expand production, predictable delivery timelines accelerate time-to-market for new SKUs, and reliable after-sales service minimizes production interruptions due to equipment issues. These factors collectively reduce total cost of ownership by shortening installation timelines and limiting downtime from spare-part delays. For procurement teams, clear warranty terms, documented inspection procedures, and accessible technical training are key negotiating points that translate supplier claims into operational confidence during commissioning and scale-up.

This supplier overview is factual and based on validated company attributes; Emiratis manufacturers should use these points as a checklist when comparing offers and requesting detailed, written responses to technical and service questions.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;