Customizable Shopping Bag Solutions for Retailers

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

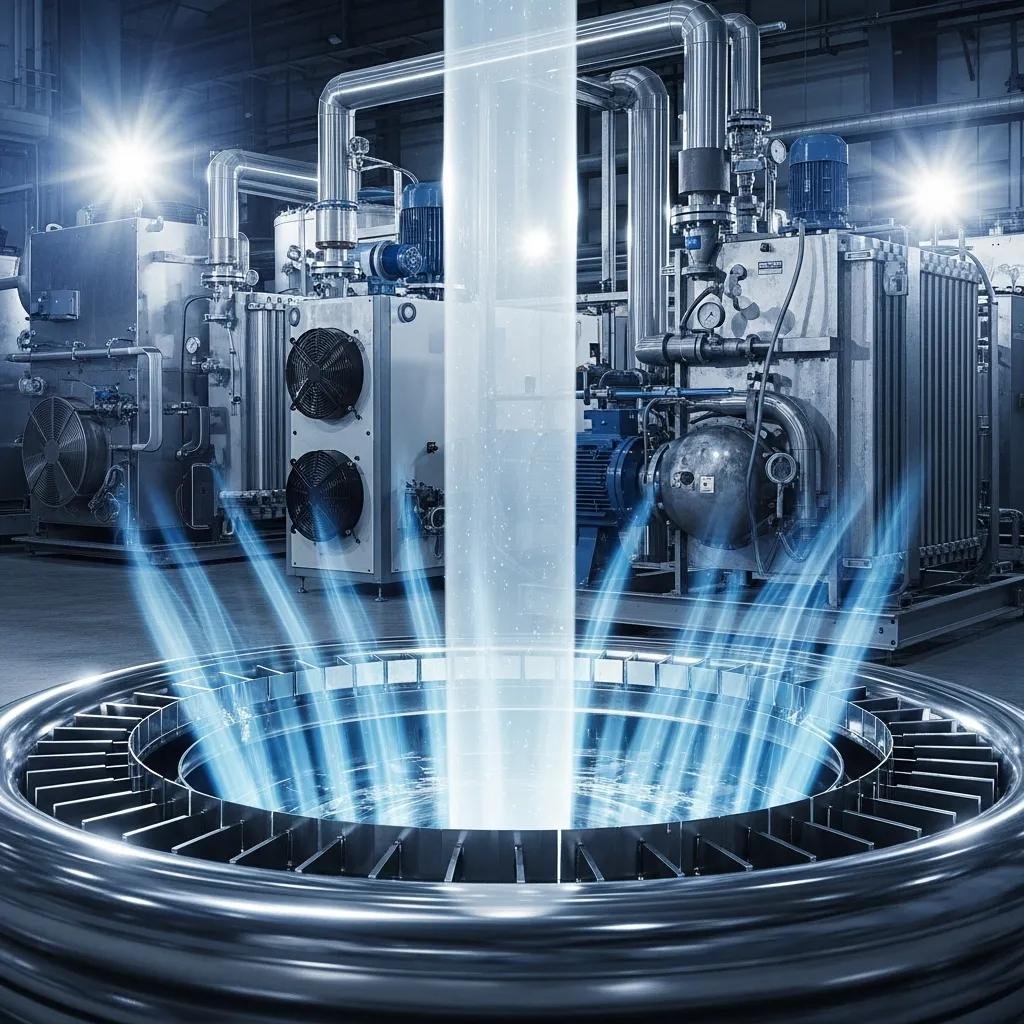

Effective heat management is crucial in plastic film production, as it directly influences the quality of the final product. This article delves into the key components of heat management, the importance of melt temperature optimization, and advanced temperature control systems that enhance extrusion efficiency. Readers will learn how to optimize extrusion temperature control to improve film quality and reduce defects, while also exploring the role of cooling technologies in the production process. Additionally, we will discuss how Kingdom Machine Co., Ltd. contributes to these advancements in thermal management.

Heat management in plastic film extrusion involves several critical components that work together to ensure optimal processing conditions. These components include the extruder barrel heating zones and cooling systems, which play vital roles in maintaining the desired temperature throughout the extrusion process. Proper heat management not only affects the melting of polymers but also influences the viscosity and flow characteristics of the material, ultimately impacting film quality.

Extruder barrel heating zones are designed to provide controlled heating to the polymer as it moves through the extrusion process. Each zone is set to a specific temperature, which is crucial for achieving the desired melting profile. The temperature distribution across these zones affects the viscosity of the polymer, which in turn influences the flow rate and the quality of the final film. For instance, if the heating zones are not properly calibrated, it can lead to uneven melting, resulting in defects such as thickness variations in the film.

Cooling systems are essential in blown film production as they help stabilize the temperature of the extruded film after it exits the die. These systems typically include air rings and water cooling systems, which rapidly cool the film to solidify it and maintain its shape. Effective cooling prevents issues such as sagging and ensures that the film retains its desired properties. Additionally, well-designed cooling systems contribute to energy efficiency by reducing the time required for the film to reach its final temperature.

Melt temperature optimization is a critical factor in enhancing the quality of plastic films. By maintaining a uniform melt temperature, manufacturers can achieve consistent film thickness and reduce the likelihood of defects. This section explores the impact of melt temperature uniformity on film production and how effective temperature control can prevent common film defects.

Uniform melt temperature is vital for producing films with consistent thickness. Variations in melt temperature can lead to differences in viscosity, which may cause uneven flow during the extrusion process. This inconsistency can result in defects such as weak spots or areas of excessive thickness. By optimizing melt temperature, manufacturers can ensure that the polymer flows evenly, leading to a more uniform film thickness and improved mechanical properties.

Temperature control is essential in preventing common defects in plastic films, such as bubbles, gels, and streaks. By closely monitoring and adjusting the melt temperature, manufacturers can mitigate these issues. For example, maintaining the correct temperature can help prevent the formation of bubbles, which occur when the polymer is overheated and begins to degrade. Effective temperature management not only enhances film quality but also improves production efficiency by reducing waste and rework.

Advanced temperature control systems play a significant role in optimizing the extrusion process. These systems include PID controllers and smart thermal management solutions that provide precise temperature regulation throughout the production cycle. By implementing these technologies, manufacturers can achieve greater efficiency and consistency in their operations.

PID (Proportional-Integral-Derivative) controllers are widely used in extrusion processes to maintain stable temperatures within the extruder. These controllers continuously monitor the temperature and make real-time adjustments to the heating elements, ensuring that the desired temperature is maintained. This level of control is crucial for achieving optimal melting and flow characteristics, ultimately leading to higher quality films.

Smart thermal management solutions leverage advanced algorithms and data analytics to optimize temperature control in real-time. These systems can predict temperature fluctuations and adjust heating and cooling processes accordingly. The benefits include improved energy efficiency, reduced production costs, and enhanced film quality. By adopting smart thermal management, manufacturers can stay competitive in the rapidly evolving plastic film industry.

Cooling technologies are integral to the blown film production process, as they ensure that the film solidifies correctly after extrusion. Various cooling methods, including air ring cooling and industrial chillers, are employed to achieve optimal cooling rates and film quality.

Air ring cooling is a widely used method in blown film production that stabilizes the frost line, which is the point at which the film begins to solidify. By directing a controlled flow of air around the film, the air ring helps maintain a consistent temperature, preventing sagging and ensuring uniform thickness. This technology is essential for producing high-quality films that meet industry standards.

Industrial chillers and heat exchangers are critical components in the cooling process of blown film production. Chillers provide a continuous supply of chilled water, which is used to cool auxiliary equipment such as air rings or rollers, rather than directly cooling the film as it exits the die. Heat exchangers help transfer heat away from the production line, maintaining optimal operating temperatures. Together, these technologies enhance cooling efficiency and contribute to the overall quality of the film.

Optimized heat management not only improves film quality but also contributes to energy efficiency and sustainability in plastic film production. By implementing effective thermal management strategies, manufacturers can reduce energy consumption and minimize their environmental impact.

Waste heat recovery systems capture excess heat generated during the extrusion process and repurpose it for other applications, such as preheating materials or heating water. This approach significantly reduces energy consumption and lowers production costs. By utilizing waste heat, manufacturers can enhance their sustainability efforts while maintaining high production efficiency.

Energy-efficient systems in plastic film production help lower greenhouse gas emissions and reduce the overall carbon footprint of manufacturing operations. By optimizing energy use and implementing renewable energy sources, companies can contribute to a more sustainable future. These systems not only benefit the environment but also improve the bottom line by reducing operational costs.

Kingdom Machine Co., Ltd. provides innovative solutions for thermal management in plastic film production, ensuring that manufacturers can achieve optimal heat control throughout the extrusion process. Their advanced equipment is designed to enhance efficiency and improve film quality.

Kingdom Machine’s blown film extruders are equipped with state-of-the-art temperature control systems, including precise PID controllers and advanced cooling technologies. These features allow for accurate temperature regulation, ensuring that the polymer is processed under optimal conditions. The result is high-quality films with consistent properties that meet industry standards.

Clients utilizing Kingdom Machine’s thermal technologies have reported significant improvements in production efficiency and film quality. By implementing these advanced solutions, manufacturers have been able to reduce defects, lower energy consumption, and enhance overall productivity. Success stories highlight the effectiveness of Kingdom Machine’s equipment in optimizing heat management for plastic film production.

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

Learn about effective plastic recycling strategies implemented across Europe. Join the movement towards sustainability and reduce environmental impact today.

Learn how to effectively launch a high-volume bag production facility with our detailed case study. Optimize operations and maximize returns today!

Elevate your food safety with innovative plastic packaging. Our food-grade bags and films enhance freshness, ensuring quality and longevity in every bite.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;

film blown machine, blown film extrusion, plastic bag making machine

At Kingdom Machinery Co., Ltd., we specialize in providing high-quality machinery tailored for the plastic bag and blown film manufacturing industries. Our commitment to excellence ensures that our clients receive reliable and efficient equipment that meets their specific production needs.

With years of experience in the industry, we understand the challenges faced by manufacturers. That's why we offer a range of machines designed to enhance productivity while maintaining top-notch quality. From automatic T-shirt bag making machines to advanced blown film machines, our products are engineered to deliver superior performance and durability.

Our commitment to innovation sets us apart in the plastic machinery industry. We continuously invest in research and development to integrate the latest technology into our machines, ensuring they operate at peak efficiency and produce high-quality products.

For instance, our advanced film blowing machines utilize cutting-edge technology to optimize the extrusion process, resulting in consistent film thickness and excellent tensile strength. This not only enhances the quality of the finished product but also reduces material waste, making our machines an eco-friendly choice for manufacturers.

At Kingdom Machinery, we prioritize our customers' needs and satisfaction. Our dedicated support team is available to assist clients throughout the entire process, from selecting the right machinery to providing after-sales service and maintenance.

We believe that strong customer relationships are built on trust and reliability. That's why we offer flexible customization options for our machines, ensuring they fit seamlessly into our clients' production lines. Our timely after-sales service further reinforces our commitment to providing exceptional support.

As a leading manufacturer of plastic bag machinery, we recognize the importance of environmental sustainability. Our machines are designed to minimize energy consumption and reduce waste, aligning with global efforts to promote eco-friendly manufacturing practices.

We also offer a range of recycling machines that facilitate the processing of plastic waste into reusable materials, helping businesses contribute to a circular economy. By choosing our machinery, clients not only improve their production efficiency but also play a vital role in protecting the environment.