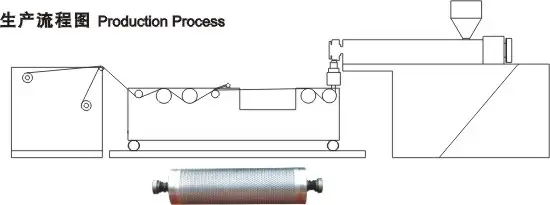

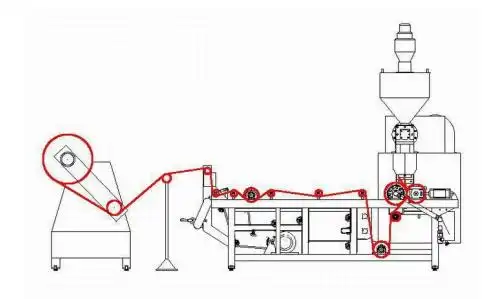

The 2-layer air bubble film machine, known as the air bubble wrap film extrusion device, utilizes Low Density Polyethylene (LDPE) and recycled LDPE materials for production. It is offered in widths of 1200mm, 1500mm, 2000mm, 2500mm, and 3000mm, incorporating two layers of bubble film. This equipment functions on power inputs of 220V, 380V, 440V, or 480V, and generates bubble film in a variety of colors like red, blue, and yellow. Its uncomplicated design and user-friendly operation render it suitable for continuous round-the-clock usage.

two layers air bubble film machines

two layers air bubble film machine

Main Technical Variables:

| Model | KDPE-1000 | KDPE-1200 | KDPE-1500 |

| Raw Material | LDPE | LDPE | LDPE |

| Screw Diameter | φ65mm | φ75mm | φ90mm |

| Film Width | 1000mm | 1200mm | 1500mm |

| Film Layer | Two Layers | Two Layers | Two Layers |

| Bubble Hole Diameter(mm) | 6,8,10,12,14,16,18,20mm | ||

| Film Color | Transparent,Black,Red,White,blue…bag color changed by masterbatch | ||

| Output | 50kg/h | 60kg/h | 70kg/h |

| Total Power | 48kw | 58kw | 68kw |

| L/D Ratio Of Screw | 28:1 | 28:1 | 28:1 |

| Water Consumption | 0.5m3/h | 0.5m3/h | 0.5m3/h |

| Machine Weight | 3 | 4 | 5 |

| Power Voltage | 220V,380V,440V | ||

| Air Shaft Diamater | without paper core ,58mm,76mm | ||

| Machine Working Time | 24 hours*7 | 24 hours*7 | 24 hours*7 |

| Warranty | 1 year | ||

| Technical Assistance | Engineers available to service machinery overseas | ||

two layers air bubble film machines

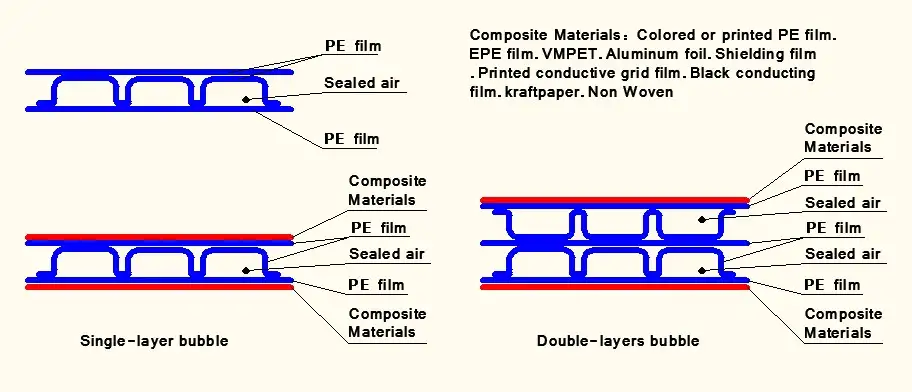

air bubble wrap film bubble bag

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

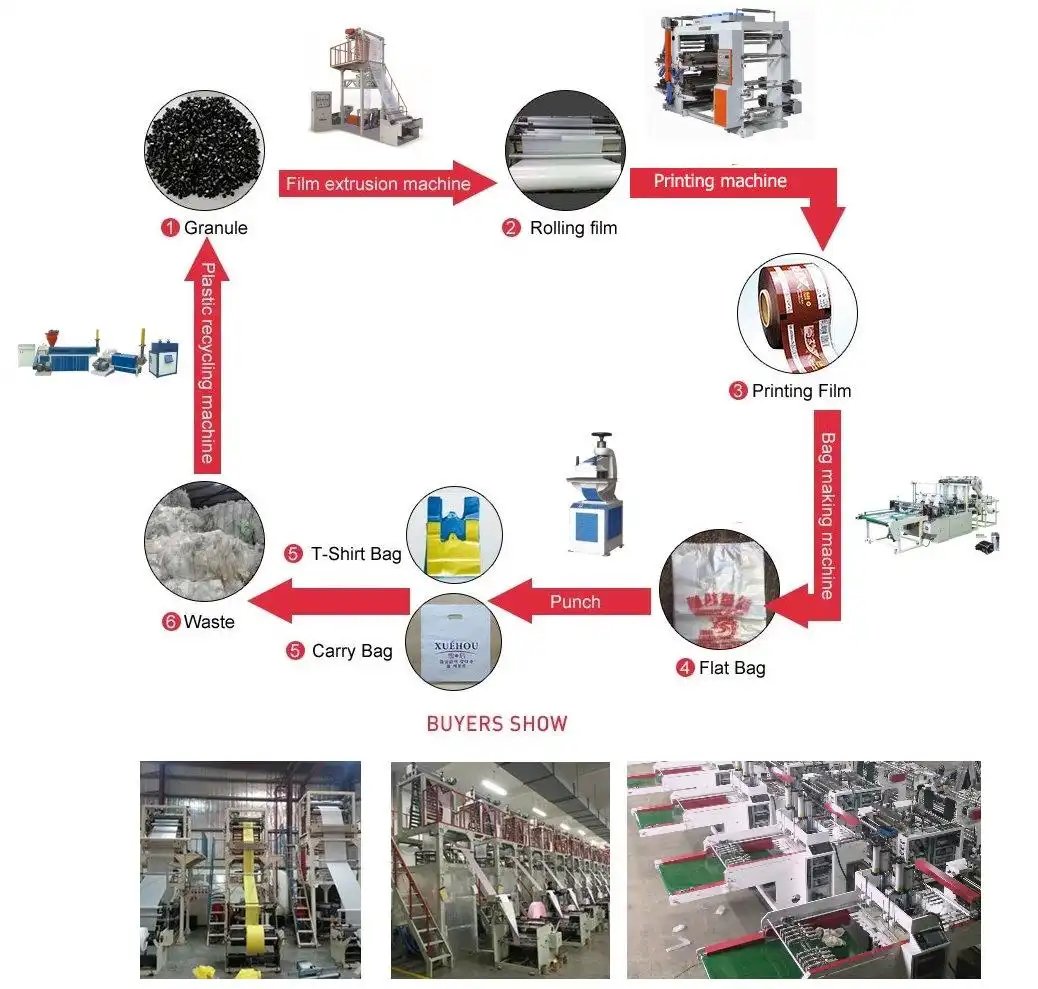

Bubble Film Machine Working in Customer Factory

two layers air bubble film machines

Install Strech Film Machine in Customer Factory

install machines in customers factory

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;