Customizable Shopping Bag Solutions for Retailers

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

Melt purity is a critical factor in the plastic extrusion and recycling processes, directly influencing product quality and operational efficiency. This article delves into the importance of maintaining melt purity and how efficient screen changer systems play a pivotal role in achieving this goal. Readers will learn about the mechanisms of melt contamination, the types of screen changers available, and the benefits of using polymer melt purification equipment. Additionally, we will explore best practices for troubleshooting and maintaining melt filtration systems, ensuring optimal performance in plastic production. By understanding these concepts, manufacturers can enhance their production processes and reduce waste, ultimately leading to more sustainable practices in the plastic industry.

Melt purity refers to the cleanliness of the polymer melt during the extrusion process, which is essential for producing high-quality plastic products. Maintaining melt purity ensures that the final products are free from contaminants that can compromise their integrity and performance. Contaminants can lead to defects, affecting both the aesthetic and functional properties of the plastic. Therefore, understanding melt purity is crucial for manufacturers aiming to optimize their production efficiency and product quality.

Melt contamination can significantly impact product quality and production efficiency. Contaminants such as dirt, dust, and foreign materials can lead to defects in the final product, including discoloration, weak spots, and inconsistent thickness. These defects not only compromise the aesthetic appeal of the products but also affect their mechanical properties, leading to potential failures in application. Additionally, contamination can cause production delays as manufacturers may need to halt operations to clean equipment or address quality issues, resulting in increased costs and reduced output.

Common sources of contaminants in polymer melt include material impurities, environmental factors, and process-related issues. Material impurities can arise from the raw materials used in production, such as recycled plastics that may contain residual contaminants. Environmental factors, such as dust and airborne particles, can also contribute to contamination during the extrusion process. Furthermore, process-related issues, such as inadequate cleaning of equipment or improper handling of materials, can introduce contaminants into the melt, compromising its purity.

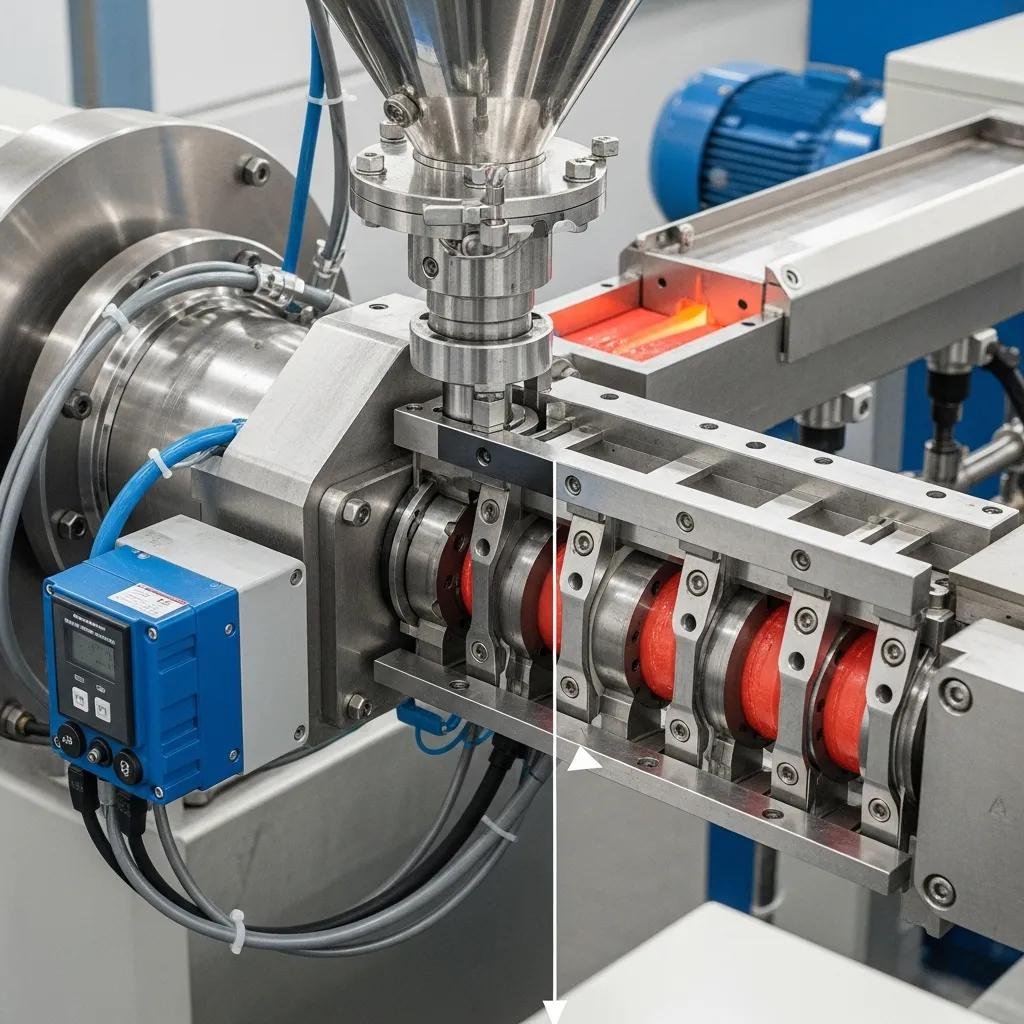

Screen changer systems are essential for ensuring continuous melt filtration during the extrusion process. These systems effectively remove contaminants from the polymer melt, maintaining its purity and quality. By employing various filtration techniques, screen changers help prevent blockages and ensure a smooth flow of material through the extruder, which is vital for consistent product quality.

There are three primary types of screen changers: manual, hydraulic, and continuous. Manual screen changers require operators to stop the extrusion process to change the filter screens, which can lead to downtime. Hydraulic screen changers automate this process, allowing for quicker screen changes without halting production. Continuous screen changers, on the other hand, provide the most efficient solution by enabling uninterrupted filtration, significantly reducing downtime and enhancing overall production efficiency.

Continuous screen changers reduce downtime in plastic production by allowing for seamless filtration without interrupting the extrusion process. This system operates by using two or more filter screens that can be alternated, ensuring that one screen is always in use while the other is being cleaned or replaced. As a result, manufacturers can maintain a steady flow of production, minimizing delays and maximizing output, which is crucial for meeting market demands.

Using polymer melt purification equipment in blown film extrusion offers several benefits, including improved product quality, reduced scrap rates, and enhanced production efficiency. By ensuring that the polymer melt is free from contaminants, manufacturers can produce higher-quality films that meet stringent industry standards. Additionally, reducing scrap rates leads to cost savings and a more sustainable production process.

Melt purity directly influences the quality and consistency of blown film products. When the polymer melt is free from contaminants, the resulting films exhibit better surface quality, mechanical properties, and uniform thickness. This consistency is essential for applications that require precise specifications, such as packaging materials. By maintaining melt purity, manufacturers can ensure that their products meet customer expectations and regulatory requirements.

Screen changers play a vital role in protecting extrusion equipment and reducing scrap by filtering out contaminants before they can cause damage. By preventing foreign materials from entering the extruder, screen changers help maintain the integrity of the equipment, reducing wear and tear. This proactive approach not only extends the lifespan of the machinery but also minimizes the amount of scrap produced due to defects, leading to a more efficient and cost-effective production process.

Melt filtration is crucial in plastic recycling processes, as it ensures that the recycled materials are free from contaminants that could compromise their quality. Efficient filtration systems help produce high-grade recycled pellets that can be used in various applications, promoting sustainability in the plastic industry.

Efficient recycling plastic melt filtration is critical for producing high-grade recycled pellets that meet industry standards. Contaminants in recycled materials can lead to inferior quality pellets, which may not be suitable for certain applications. By implementing effective melt filtration systems, manufacturers can ensure that the recycled pellets maintain their integrity and performance, making them viable alternatives to virgin materials.

Screen changer systems are designed to handle contaminated post-consumer recycled plastics by effectively filtering out impurities during the extrusion process. These systems can accommodate varying levels of contamination, ensuring that the final recycled products meet quality standards. By utilizing advanced filtration techniques, screen changers help manufacturers produce high-quality recycled materials that contribute to a circular economy.

Screen changer systems must be compatible with existing extrusion and recycling equipment to ensure optimal performance. Features such as integration capabilities, performance enhancements, and customization options are essential for achieving seamless operation.

Kingdom Machine Co., Ltd. integrates advanced melt filtration technologies into their extrusion and recycling equipment to enhance performance. By utilizing high-quality screen changers, the company ensures that their machines operate efficiently, producing high-quality plastic products while minimizing downtime and maintenance needs.

Efficient screen changers for plastic film and bag production possess several key attributes, including high filtration capacity, ease of maintenance, and adaptability to various production processes. These features enable manufacturers to maintain melt purity while optimizing their production workflows, ultimately leading to improved product quality and reduced operational costs.

Implementing best practices for troubleshooting and maintaining melt filtration systems is essential for ensuring optimal performance. Regular maintenance schedules, staff training, and proactive identification of potential issues can help manufacturers avoid costly downtime and maintain product quality.

Identifying and resolving melt contamination issues in extrusion lines involves monitoring for signs of contamination, such as product defects or irregular flow rates. Manufacturers should implement routine inspections and testing to detect contaminants early, allowing for timely interventions that can prevent further issues.

To ensure optimal screen changer performance, manufacturers should adopt maintenance strategies that include regular cleaning, timely screen replacements, and thorough inspections. Establishing a routine maintenance schedule helps prevent contamination issues and extends the lifespan of the equipment, ultimately contributing to a more efficient production process.

| Screen Changer Type | Advantages | Disadvantages |

|---|---|---|

| Manual | Low cost, simple design | High downtime, labor-intensive |

| Hydraulic | Automated operation, reduced downtime | Higher initial investment, more complex maintenance |

| Continuous | Uninterrupted filtration, maximum efficiency | Higher cost, requires advanced technology |

In conclusion, ensuring melt purity through efficient screen changer systems is vital for optimizing plastic extrusion and recycling processes. By understanding the importance of melt purity, the types of screen changers available, and best practices for maintenance, manufacturers can enhance product quality, reduce waste, and promote sustainability in the plastic industry.

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

Learn about effective plastic recycling strategies implemented across Europe. Join the movement towards sustainability and reduce environmental impact today.

Learn how to effectively launch a high-volume bag production facility with our detailed case study. Optimize operations and maximize returns today!

Elevate your food safety with innovative plastic packaging. Our food-grade bags and films enhance freshness, ensuring quality and longevity in every bite.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;