Customizable Shopping Bag Solutions for Retailers

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

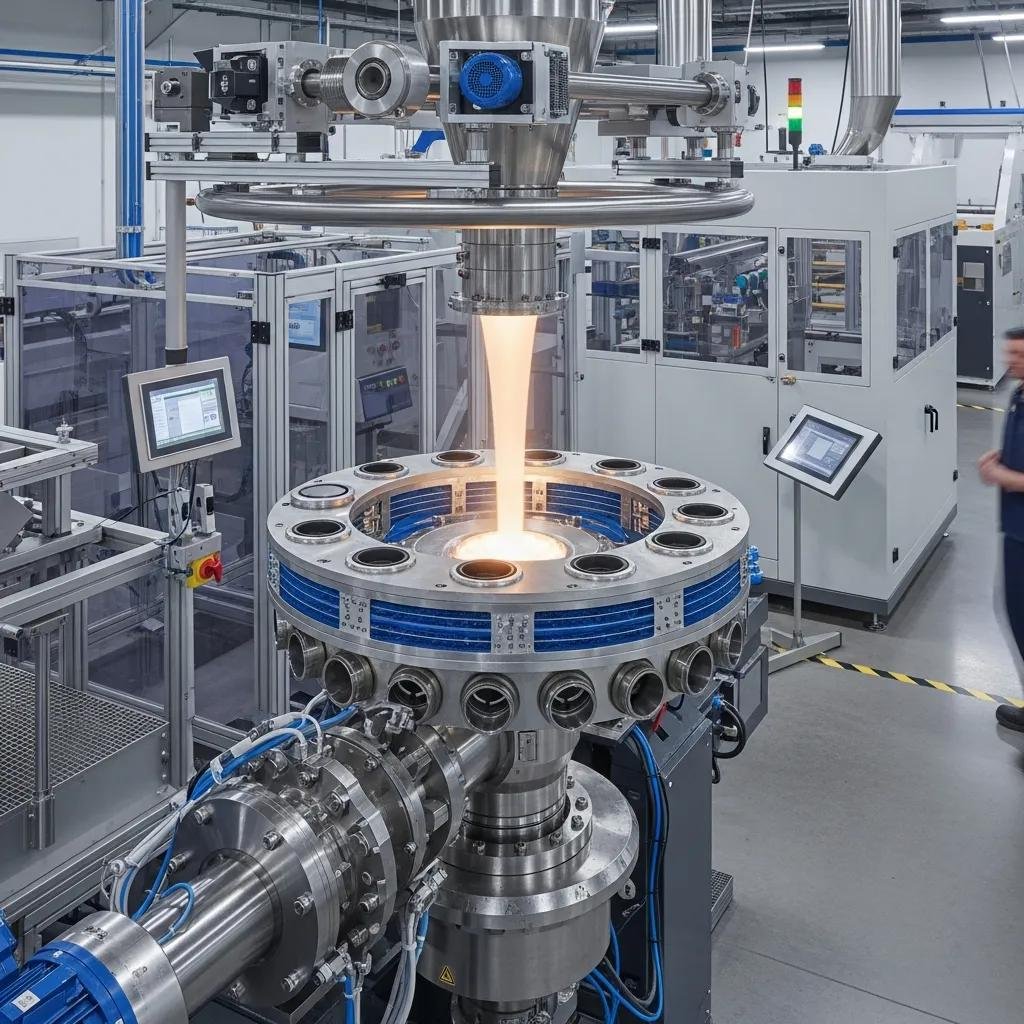

In the realm of blown film extrusion, optimizing film cooling is crucial for achieving high-quality plastic films. Advanced air ring technology plays a pivotal role in this process, enhancing cooling efficiency and film quality. This article delves into the mechanisms, benefits, and innovations surrounding air ring technology, providing insights into how it can significantly improve production outcomes. Many manufacturers face challenges in maintaining consistent film quality and production efficiency, but advanced air ring systems offer a solution by stabilizing the film bubble and optimizing cooling processes. We will explore the role of air rings in film cooling, the types of air rings available, and how Kingdom Machine Co., Ltd. leverages this technology to enhance blown film extrusion performance.

Advanced air ring technology is integral to the blown film cooling process, as it stabilizes the film bubble and ensures uniform cooling. By directing airflow precisely around the film, air rings help maintain the desired temperature and pressure, which is essential for producing high-quality films. This technology not only enhances cooling efficiency but also contributes to the overall quality of the plastic film produced. The importance of air ring technology cannot be overstated, as it directly impacts the mechanical properties and clarity of the final product.

Air rings stabilize the film bubble by creating a controlled airflow that envelops the bubble as it is formed. This airflow helps to maintain the bubble’s shape and size, preventing defects such as sagging or uneven thickness. Techniques such as adjusting the airflow rate and optimizing the design of the air ring contribute to effective stabilization. The result is a more consistent film thickness and improved mechanical properties, which are critical for applications requiring high-performance films.

Optimized film cooling significantly enhances the quality of plastic films by ensuring uniform thickness and reducing defects. When cooling is efficient, the film solidifies properly, leading to better mechanical properties such as tensile strength and clarity. Studies have shown that films produced with optimized cooling exhibit fewer defects and improved performance characteristics, making them suitable for a wider range of applications. This improvement in quality not only meets industry standards but also enhances customer satisfaction.

Various types of advanced air rings are designed to enhance film cooling efficiency, each offering unique benefits. These include dual-lip air rings, multi-lip air rings, and automatic air ring systems. Each design is tailored to specific production needs, allowing manufacturers to choose the most suitable option for their operations.

Dual-lip and multi-lip air ring designs provide several advantages, including improved airflow distribution and enhanced cooling efficiency. The dual-lip design allows for better control of the air pressure around the film bubble, while multi-lip designs can create a more uniform cooling effect. These features contribute to higher film quality and reduced production waste, making them popular choices among manufacturers.

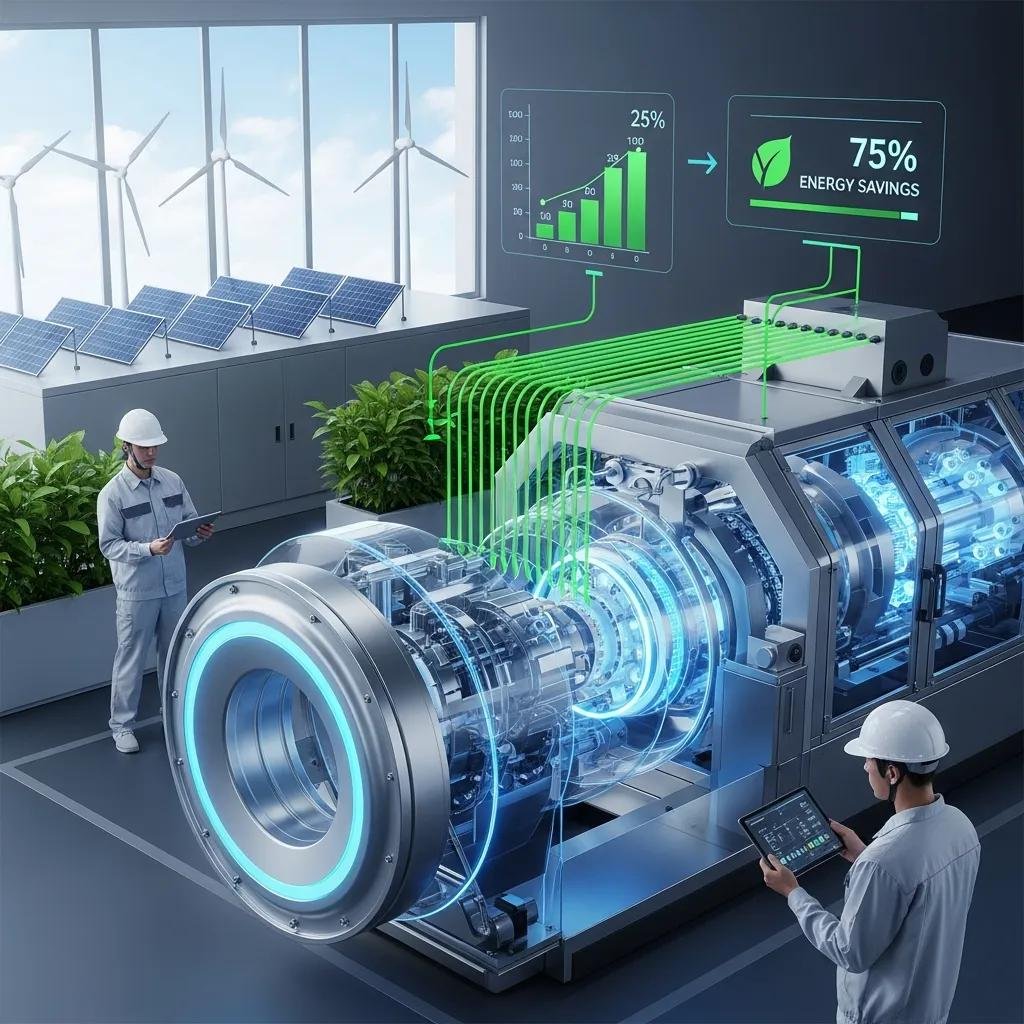

Automatic air ring systems utilize advanced sensors and controls to adjust airflow in real-time, ensuring optimal cooling conditions throughout the extrusion process. This automation allows for precise control over the cooling parameters, leading to consistent film quality and reduced energy consumption. By minimizing human error and optimizing performance, these systems significantly enhance overall production efficiency.

Kingdom Machine Co., Ltd. has developed advanced air ring technology that optimizes blown film extrusion output through precision airflow control and energy-saving innovations. Their systems are designed to enhance bubble stability and improve cooling efficiency, resulting in higher production rates and better film quality.

The precision airflow control features of Kingdom Machine’s air rings include adjustable airflow rates and customizable nozzle designs. These features allow operators to fine-tune the cooling process, ensuring that the film bubble remains stable during production. By maintaining optimal conditions, manufacturers can achieve consistent film quality and reduce the likelihood of defects.

Energy-saving innovations in Kingdom Machine’s air ring technology help reduce operational costs while maintaining high production efficiency. By optimizing airflow and minimizing energy consumption, these systems not only lower energy bills but also contribute to a more sustainable production process. This focus on efficiency aligns with industry trends towards reducing environmental impact while maximizing output.

The integration of advanced air ring technology with internal bubble cooling and automation systems enhances the overall efficiency of the blown film extrusion process. This combination allows for more effective cooling and stabilization of the film bubble, leading to improved production outcomes.

Combining air rings with internal bubble cooling (IBC) systems offers several advantages, including enhanced cooling efficiency and improved film quality. IBC systems work in tandem with air rings to provide a more uniform cooling effect, which is essential for producing high-quality films. This integration also allows for better control over the cooling process, reducing the risk of defects and improving overall production efficiency.

AI-driven controls in modern air ring systems enhance film cooling consistency by utilizing data analytics to optimize airflow and cooling parameters. These systems can adapt to changing production conditions in real-time, ensuring that the film bubble remains stable and cool throughout the extrusion process. This level of control leads to higher quality films and increased production efficiency.

As the blown film extrusion industry evolves, several trends are shaping the future of film cooling technology. These include advancements in automation, the integration of AI, and a growing emphasis on sustainability.

AI is transforming blown film extrusion by enabling smarter, more efficient production processes. Through predictive analytics and real-time monitoring, AI systems can optimize cooling parameters and improve overall production efficiency. This technology not only enhances film quality but also reduces waste and energy consumption, aligning with industry goals for sustainability.What role does sustainability play in advanced film cooling solutions?

Sustainability is becoming increasingly important in the development of advanced film cooling solutions. Manufacturers are focusing on reducing energy consumption and minimizing waste throughout the production process. By implementing energy-efficient technologies and sustainable practices, companies can meet regulatory requirements and respond to consumer demand for environmentally friendly products.

Choosing Kingdom Machine Co., Ltd. for advanced blown film air ring and cooling solutions offers several unique advantages. Their commitment to innovation and quality ensures that customers receive state-of-the-art technology designed to enhance production efficiency and film quality.

Kingdom Machine’s technology is distinguished by its advanced design features, including customizable air ring configurations and precision airflow control. Additionally, their customer support services provide comprehensive training and assistance, ensuring that clients can maximize the benefits of their equipment. This focus on quality and service sets Kingdom Machine apart in the industry.

Customer case studies highlight the significant performance improvements achieved through the use of Kingdom Machine’s air ring technology. Many clients report enhanced film quality, increased production rates, and reduced energy consumption, demonstrating the effectiveness of their solutions in real-world applications. These success stories underscore the value of investing in advanced air ring technology for blown film extrusion.

| Air Ring Type | Design Features | Benefits |

|---|---|---|

| Dual-Lip Air Ring | Enhanced airflow control | Improved film stability and quality |

| Multi-Lip Air Ring | Uniform cooling distribution | Reduced defects and waste |

| Automatic Air Ring System | Real-time airflow adjustments | Consistent film quality and energy savings |

The table above summarizes the various air ring types and their respective benefits, illustrating how different designs contribute to improved film cooling efficiency and quality.

In conclusion, optimizing film cooling with advanced air ring technology is essential for enhancing blown film extrusion performance. By understanding the role of air rings, the types available, and the innovations offered by Kingdom Machine Co., Ltd., manufacturers can make informed decisions that lead to improved production outcomes and higher quality films.

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

Learn about effective plastic recycling strategies implemented across Europe. Join the movement towards sustainability and reduce environmental impact today.

Learn how to effectively launch a high-volume bag production facility with our detailed case study. Optimize operations and maximize returns today!

Elevate your food safety with innovative plastic packaging. Our food-grade bags and films enhance freshness, ensuring quality and longevity in every bite.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;