The One Layer Stretch Film Machine is characterized by the following attributes:

– It can run at speeds of up to 800 meters per minute.

– The machine boasts high efficiency in production and facilitates quick changeovers.

– Its fully automated operations are overseen by a Programmable Logic Controller (PLC).

– The machine can handle paper cores of 1, 2, or 3-inch diameters.

– It rewinds film without stretching, ensuring proper tension.

– Compatible with LLDPE stretch film, PVC stretch film, LLDPE cling wrap film, and PVC food wrap film.

– Capable of rewinding film from large rolls to small rolls.

– It features inverter control for customizable rewinding speeds, promoting power efficiency and cost-effectiveness.

– The machine accommodates film widths from 100mm to 500mm and includes a meter counter.

– It comes with a one-year warranty, supporting continuous 24/7 operation.

– Designed for user-friendliness to facilitate easy operation.

– Economically designed to cater to newcomers or beginners in the industry.

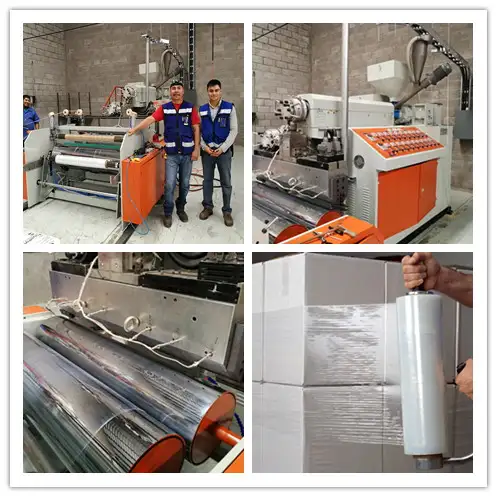

One Layer Stretch Film Machine

This particular device utilizes a variety of materials including LLDPE, LDPE, CaCO3 compounds, recycled materials, biodegradable materials, masterbatch, and additives. Through the control of the inverter, the speed of the film extruder is regulated, resulting in energy efficiency, environmental friendliness, and cost-effectiveness. The film thickness ranges from 0.017mm to 0.04mm, with widths ranging from 100mm to 500mm, making it suitable for applications like stretch film, pallet packing, carton packing, building material packing, auto parts packing, hardware packing, and luggage wrap packing. The screw material, 38CrMoAl, ensures long-lasting durability. Backed by a one-year warranty, this machine can operate around the clock. Its user-friendly design and cost-effective structure make it an ideal choice for newcomers to the industry. The power supply configuration can be tailored to different regions, whether it be 220V, 380V, 440V, or 480V.

Optional Equipment:

1)Auto load

2)Auto dry hopper

3)Motorize net changer

4)Hydraulic net changer

5)gule pump

6.air compressor

7.Chiller

8.Waste film crush online

Main Technical Parameter

| Model | KD-50 | KD-75 |

| Material | LLDPE,LDPE,biodegradable material | |

| Screw Diameter | Φ50mm | Φ75mm |

| Film Layer | One layer | One layer |

| L/D Ratio Of Screw | 30:1 | 30:1 |

| Speed of Screw | 10-120rpm | 10-120rpm |

| Film Width | 200-500mm | 200-1000mm |

| Film Thickness | 0.017-0.04mm | 0.017-0.04mm |

| Main Motor Power | 11kw | 30kw |

| Film Color | Transparent,Black,Red,White,blue…bag color changed by mastbatch | |

| Max Output | 35kg | 80kg |

| Heating power | 15KW | 40KW |

| Water Consumption | 0.5m3/h | 0.5m3/h |

| Air Comsumption | 3m3/h | 3m3/h |

| Machine Weight | 3T | 4T |

| Overall Dimensions(L*W*H) | 56*15*18cm | 60*15*25cm |

| Total Power | 40kw | 80kw |

| Power Voltage | 220V,380V,440V | 220V,380V,440V |

| Machine Working time | 24 hours*7 | 24 hours*7 |

| Material Core Diamater | 76mm(3 inch) | 76mm(3 inch) |

| Warranty | 1 year | 1 year |

| Technical Assistance | Engineers available to service machinery overseas | |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Stretch film machine.

Extrusion Film Extrusion use Polyethelene.

Linear Low Density Polyethylene(LLDPE):

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

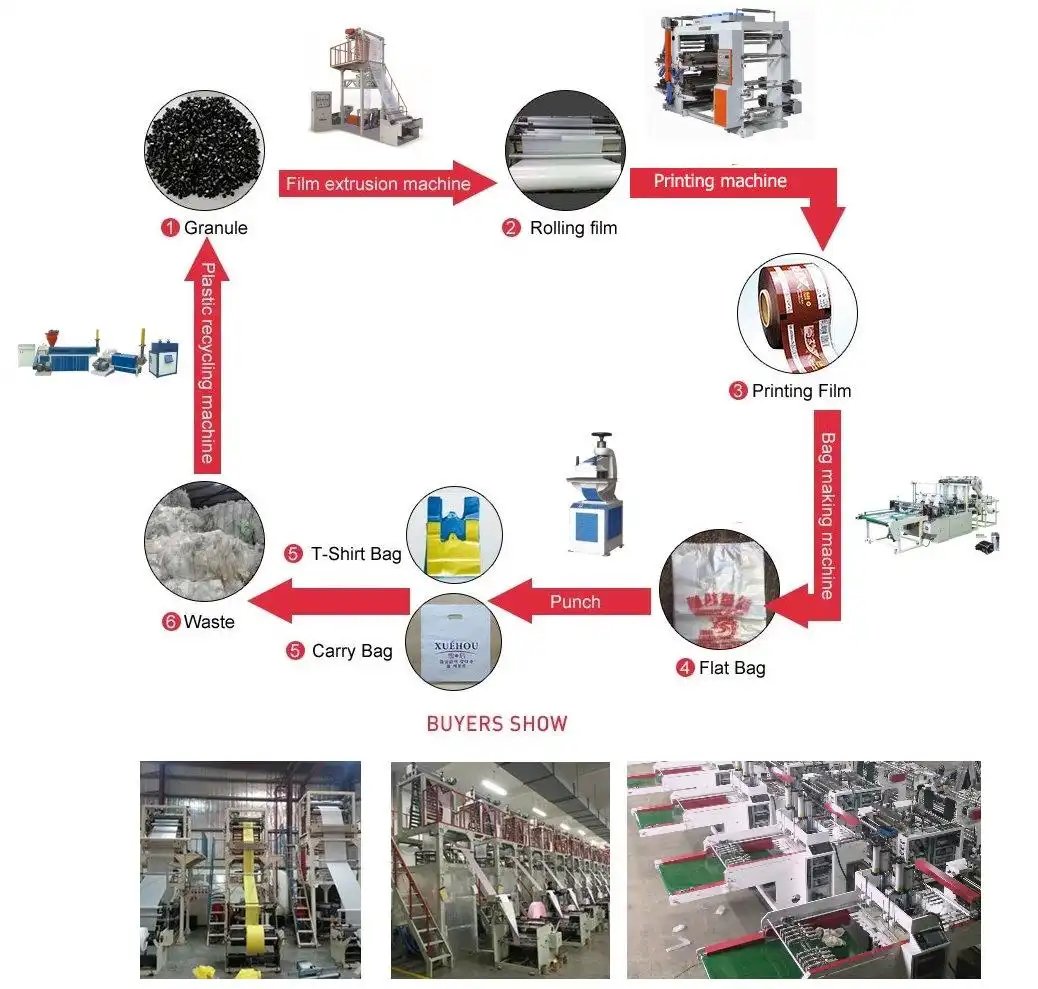

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;