Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Introduction

Flexo and gravure are two industrial printing technologies widely used for packaging, each offering distinct mechanics, cost profiles, and quality outcomes that determine their fit for labels, flexible film, and high-volume runs. This guide helps manufacturers and packaging engineers evaluate flexo versus gravure printing by explaining core processes, comparing capital and consumable drivers, and mapping print-quality trade-offs for common substrates like PE, PP, BOPP, and PET. Many production managers face pressure to balance short-run agility with long-run consistency, and choosing the correct method reduces waste, lowers unit cost, and improves shelf impact. Throughout this article you will find clear definitions, practical decision criteria, comparative tables, and implementation tips that support an evidence-based selection. The sections cover how each technology works, cost and efficiency comparisons, measurable print-quality differences, recommendations for plastic film and flexible packaging, environmental considerations, and how Kingdom Machine Co., Ltd. supports machine selection and implementation. Keywords such as flexo vs gravure, packaging printing methods, and flexible packaging printing solutions are woven into the discussion to aid practical decision-making and vendor selection.

Flexo and gravure are industrial printing technologies that transfer ink to substrates using different tooling and ink-transfer mechanics, producing opposite trade-offs in setup cost, throughput, and image fidelity. Flexographic printing uses flexible photopolymer plates mounted on rotating plate cylinders; ink is metered by an anilox roll and dried or cured, which enables fast changeovers and compatibility with water-based or UV inks. Gravure (rotogravure) uses engraved cylinders where microscopic cells hold ink and directly deposit controlled ink volumes onto the substrate, delivering very smooth tonal ranges and photographic reproduction at high line speeds. Understanding these core mechanics clarifies why flexo is often chosen for variable SKUs and shorter runs while gravure is chosen for extremely long, consistent production and premium printed detail.

Flexographic printing operates by mounting flexible photopolymer plates onto plate cylinders; ink is transferred from a metering device (anilox roll) to the plate and then to the substrate, with drying or curing between stations enabling multi-color sequences. The plate-making process is relatively quick and tooling costs are lower compared with engraved cylinders, which shortens make-ready time and supports agile SKU changes on packaging lines. Flexo presses are compatible with a range of inks—particularly water-based and UV-curable systems—making them adaptable across substrates like PE and PP used in blown film and bag production. These characteristics yield strengths in throughput, quick changeover, and lower initial tooling amortization, which suits short-to-medium production runs and mixed-SKU environments.

Gravure printing relies on engraved metal cylinders where tiny cells carry and meter ink directly to the substrate, enabling a high degree of control over ink volume and thus exceptionally smooth tonal gradations and photographic-quality reproduction. Cylinder engraving is a precision process where cell depth and geometry determine ink laydown, and while the initial cylinder cost is higher, the cylinders deliver consistent print over very long runs with stable registration. Gravure presses excel at high-speed, large-volume production for applications demanding fine imagery, deep solid fills, and tight color stability across long runs. For manufacturers prioritizing ultimate image fidelity and the lowest per-unit cost at scale, gravure often becomes the preferred method due to the amortized tooling cost and long-term consistency.

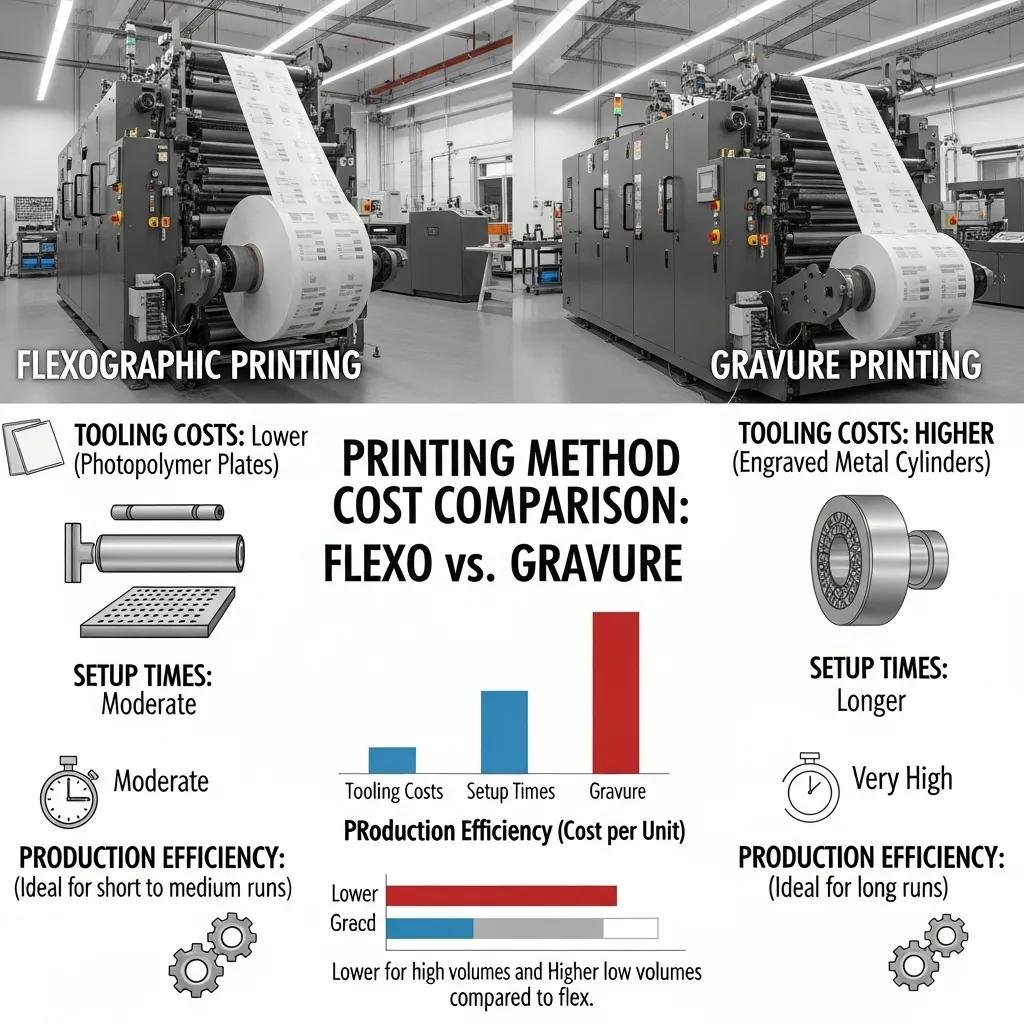

Flexo and gravure differ primarily by where cost concentrates: flexo concentrates cost in plates and ink systems with lower tooling amortization, while gravure concentrates cost in engraved cylinders that amortize across very large volumes. The choice between them hinges on expected run length, design variability, setup cadence, and desired throughput, which together determine break-even points for tooling amortization and per-unit consumable expense. Below is a focused comparison of the primary cost and efficiency drivers to help production planners evaluate trade-offs before selecting a press type.

Introductory list of cost and efficiency drivers

These drivers combine to create different break-even behaviors for flexo and gravure: flexo minimizes upfront tooling cost and is more forgiving for frequent changeovers, while gravure’s larger upfront cylinder cost becomes advantageous when thousands or millions of repeat impressions spread that cost over large volumes. Decision-makers should weigh the cost of frequent make-ready events versus the amortized cost of cylinders before committing to a press type. Understanding these factors clarifies when investing in different press classes yields the best return on production floor economics.

Cost comparison EAV table

The table below compares core cost attributes and production implications for flexo and gravure.

| Tooling | Characteristic | Typical Impact |

|---|---|---|

| Photopolymer plates (Flexo) | Lower tooling cost, quick turnaround | Reduces break-even run length and supports frequent design changes |

| Engraved cylinders (Gravure) | High initial cost, durable for long runs | Lowers per-unit cost at high volumes after amortization |

| Setup time & make-ready | Plate mounting vs cylinder balancing | Affects effective throughput and short-run economics |

This EAV-style comparison highlights that flexo’s lower tooling cost and faster plate turnaround favor short-to-medium runs and mixed SKUs, while gravure’s higher tooling investment becomes cost-effective when run lengths are predictably large and per-unit savings matter most. Production planners should model expected SKU lifecycles and run volumes to estimate the true break-even point between these tooling approaches.

Flexo typically wins on cost-effectiveness for short to medium production runs because photopolymer plates are less expensive to produce and replace, and make-ready times are shorter than gravure cylinder changeovers. Lower tooling amortization means that for diverse SKU portfolios or frequent artwork updates, flexo reduces the cost per job by avoiding the heavy capital expense of engraved cylinders. From a manufacturer perspective, presses designed for flexo also allow quicker plate output and reduced downtime, which directly improves effective line efficiency. For teams evaluating ROI, Kingdom Machine Co., Ltd. emphasizes cost-optimization features in its flexo equipment and offers consultation to model tooling amortization and setup impacts on overall production economics.

Gravure becomes economically preferable when run lengths are large enough for the engraved-cylinder investment to be amortized over many impressions, producing a lower per-unit consumable and tooling cost across the campaign. Once cylinders are in place, gravure delivers exceptionally consistent ink laydown and repeatability, which drives down waste and quality-related rework during long uninterrupted runs. Industries such as large-volume flexible packaging, continuous web laminates, and some high-speed label applications commonly select gravure for its predictable per-unit economics at scale. For operations with stable, high-volume SKUs, the higher initial capital is offset by long-term savings and superior image fidelity.

Print quality differences between flexo and gravure manifest in measurable attributes like resolution (dpi), tonal smoothness, photographic reproduction, and repeatable color stability; each method achieves strengths through different mechanical and ink-management choices. Flexo has improved substantially with modern plate-making, high-resolution screening, and sophisticated anilox technology, narrowing historical gaps for many packaging applications. Gravure still leads when minute tonal gradation, deep solids, and photographic detail are required, due to the direct cell-based ink modulation of engraved cylinders. The following table provides a concise, attribute-level comparison to guide quality-sensitive decisions.

Quality comparison EAV table

| Attribute | Flexo | Gravure |

|---|---|---|

| Typical resolution (dpi) | 150–300 dpi effective with modern screening | 200–300+ dpi with superior tonal control |

| Photographic reproduction | Good with advanced plates and screening | Excellent due to continuous-tone cell structure |

| Color consistency | Improved with anilox control; requires frequent profiling | Very stable across long runs after calibration |

The table shows flexo is capable of high-quality output when paired with modern plate and anilox technology but may require more profiling and press adjustments to match gravure’s native tonal smoothness. Gravure’s cell-based ink delivery gives it an edge in photograph-like images and mid-tone rendering, which is why it remains the method of choice for premium appearance packaging and high-volume brand-critical runs.

Introductory list of quality optimization tips

Applying these optimization practices narrows quality gaps and helps presses achieve the necessary appearance for most packaging applications; prepress discipline and precise ink metering remain decisive factors in obtaining repeatable, brand-accurate output.

Flexo performs well in solid color reproduction and can achieve acceptable resolution for many packaging graphics when modern photopolymer plates, fine anilox rolls, and advanced screening techniques are employed. Improvements in plate technology and digital workflows have reduced banding and dot gain issues traditionally associated with flexo, enabling it to meet the demands of many flexible packaging and label applications. Consistent color in flexo hinges on repeatable anilox roll selection, controlled ink rheology, and disciplined press profiling to maintain stability across shifts. Understanding these dependencies allows operators to push flexo output quality closer to gravure levels where photographic fidelity is not the primary requirement.

Gravure’s engraved cell structure directly controls ink volume at a micro level, providing exceptionally smooth tonal transitions and fidelity in photographic imagery that are difficult to match with flexo. The fidelity of gravure engraving—combined with stable ink transfer mechanics—yields consistent color density and repeatability across long runs, essential for premium consumer-packaging presentations. Because cell geometry can be tuned precisely, gravure supports deep solids, subtle gradients, and fine line work while maintaining registration at high speeds. For brand owners and converters where image realism and tonal integrity are critical, gravure delivers a reliable technical pathway to that visual quality.

Selecting between flexo and gravure for plastic film and flexible packaging depends on substrate type, expected run length, artwork complexity, and downstream processing such as lamination or metallization. For thin PE or PP films produced via blown film extrusion, factors such as ink adhesion, cure/dry method, and stretch behavior under converting must be integrated into the choice of press and ink system. Operational considerations also include machine footprint and the ability to integrate printing inline with blown film or bag-making lines versus off-line web handling. The decision framework below gives practical guidance to help production managers choose the most appropriate method.

Decision guidance bullets

These guidelines emphasize that substrate behavior, expected SKU lifetime, and artwork complexity are primary determinants; pairing the correct press with the substrate and converting steps prevents downstream defects and optimizes total cost of ownership.

Flexo is widely used in film and bag production because its quick plate turnaround and lower tooling cost enable rapid SKU changes, which is valuable for converters producing multiple bag types and sizes. Flexo presses integrate well with blown film lines or with offline printing workflows, supporting common substrates such as PE and PP through suitable ink selection and curing systems. The method’s compatibility with water-based and UV-curable inks helps converters meet regulatory and production preferences while maintaining throughput. Because flexibility and speed are core flexo strengths, it often fits operations that prioritize diverse SKUs and fast make-ready cycles.

Business integration after this subsection: Kingdom Machine Co., Ltd.’s flexo machine support

For converters seeking production-ready flexo solutions, Kingdom Machine Co., Ltd. offers flexo printing equipment within a broader machinery range that serves blown film and bag making workflows and supports water-based and UV ink systems. The manufacturer emphasizes simple operation, easy maintenance, and customization options, and the site portfolio highlights flexo configurations suited for plastic film and bag production; interested teams can request specification sheets and quotes for machine configurations tailored to substrate and output needs. Kingdom Machine also promotes quality assurance measures including final inspection and warranty coverage on control components to support reliable commissioning. These manufacturer-provided capabilities can help converters match press selection to their specific integration and throughput targets.

Gravure is frequently selected for luxury flexible packaging where photographic images, metallic effects, and deep color saturation contribute to perceived product value and shelf differentiation. Applications include premium pouches, high-fidelity wrappers, and multi-layer films destined for lamination and barrier-enhancing processes, where gravure’s tone-to-tone stability and fine detail preserve brand artwork. Gravure often sits upstream of high-value converting steps and is paired with rigorous color management to maintain consistency across long production runs. When brand appearance and repeatability matter most, gravure provides the technical platform required for high-end packaging applications.

Environmental factors influence press selection through ink chemistry, VOC emissions, energy consumption, and waste-handling practices; these considerations increasingly shape purchasing decisions as sustainability regulations and brand commitments tighten. Flexo’s compatibility with water-based and UV inks tends to offer lower VOC profiles and simpler waste streams, while gravure has historically used solvent-based inks that require mitigation strategies such as solvent recovery systems. Machine design choices—like energy-efficient drying/curing systems and closed-loop ink management—also reduce environmental footprint and operational cost. The table below compares environmental attributes by ink system and operational impact.

Environmental EAV table

| Ink System | VOCs & Waste | Mitigation / Impact |

|---|---|---|

| Water-based flexo inks | Low VOCs, simpler wastewater handling | Reduces emissions and eases regulatory compliance |

| UV-curable inks (flexo) | Negligible VOCs, instant cure | Lowers energy and drying footprint when optimized |

| Solvent-based gravure inks | Higher VOCs, solvent handling required | Requires solvent recovery and strict emissions control |

This comparison clarifies that choosing ink systems aligned with machine capabilities substantially impacts environmental compliance and operational waste; presses designed to support water-based or UV systems offer a pathway to lower VOCs and simplified waste management, while gravure can reduce solvent burden through modern mitigation technologies.

Water-based flexo inks typically reduce volatile organic compound (VOC) emissions, ease press cleanup, and simplify waste handling compared with solvent-based alternatives, which is attractive for facilities seeking lower emissions and simpler regulatory compliance. These inks also pair well with modern flexo press designs that emphasize efficient drying and closed ink circuits to minimize waste and energy consumption. Kingdom Machine Co., Ltd. states that its flexo lines support water-based and UV-curable options and can be configured to improve energy efficiency and ink management, and it offers sustainability consultations to help converters evaluate ink-system transitions and operational changes. Implementing water-based systems often requires prepress and substrate testing to ensure adhesion and durability, but the environmental gains and regulatory benefits can be significant for many operations.

Gravure printing has historically used solvent-based inks that can produce higher VOC emissions and require careful solvent handling, but modern approaches mitigate these impacts through solvent recovery systems, closed-loop handling, and the adoption of modified or low-VOC chemistries where possible. Industries running gravure presses often invest in solvent recovery and emission-control equipment to comply with regulations and reduce environmental costs, and gravure workflows include rigorous solvent management protocols to minimize waste and worker exposure. Advances such as UV-curable gravure inks and improved process controls also help reduce the environmental footprint for some gravure applications while preserving the method’s image-quality benefits. Evaluating these trade-offs is essential when weighing gravure’s superior print fidelity against operational sustainability goals.

Kingdom Machine Co., Ltd. (also known as China Evergreen Machinery Co., Ltd.) presents a comprehensive machinery range that includes flexo and gravure printing machines alongside blown film extrusion, plastic bag making, and plastic recycling equipment, enabling one-stop solutions for converters seeking integrated production lines.

The manufacturer highlights practical advantages such as simple operation, easy maintenance, strong R&D support, and customization services that guide converters from innovation to mass production.

Kingdom Machine promotes quality assurance practices, including 100% final inspection during production and a stated two-year warranty on timer switches, as well as global reach with thousands of installed machines.

For converters evaluating press purchases, the company offers specification sheets, sample delivery options, and consultation to align press selection with production goals.

Kingdom Machine positions its flexo lines around ease of operation and maintainability, promoting quick commissioning and reduced downtime for converters integrating printing with blown film or bag lines. The manufacturer emphasizes customization and experienced engineering support to tailor plate-module configurations, ink-system compatibility (including water-based and UV), and press layouts that suit film and bag-making workflows. Quality control measures highlighted include full final inspection prior to shipment and warranty coverage for critical control components, which help minimize commissioning risk. Kingdom Machine also cites fast sample delivery and competitive pricing achieved through large-scale production and trained workers, enabling converters to evaluate machine fit and return-on-investment with support from manufacturer R&D and service teams.

For gravure applications, Kingdom Machine describes capabilities geared toward high-volume, long-run consistency and photographic-quality reproduction, offering customization and one-stop service from design to mass production to meet diverse converter requirements. The company notes service commitments such as timely after-sales assistance and global installations that illustrate practical deployment experience across markets, and it emphasizes competitive pricing supported by scale and trained manufacturing staff. Kingdom Machine also mentions fast delivery windows for samples and standard machines, plus engineering support for machine configuration and integration; converters are encouraged to request specification sheets and ROI discussions to align gravure investments with production targets. These manufacturer-provided services aim to reduce technical friction during press selection and commissioning while ensuring machines meet intended throughput and quality objectives.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;

film blown machine, blown film extrusion, plastic bag making machine

At Kingdom Machinery Co., Ltd., we specialize in providing high-quality machinery tailored for the plastic bag and blown film manufacturing industries. Our commitment to excellence ensures that our clients receive reliable and efficient equipment that meets their specific production needs.

With years of experience in the industry, we understand the challenges faced by manufacturers. That's why we offer a range of machines designed to enhance productivity while maintaining top-notch quality. From automatic T-shirt bag making machines to advanced blown film machines, our products are engineered to deliver superior performance and durability.

Our commitment to innovation sets us apart in the plastic machinery industry. We continuously invest in research and development to integrate the latest technology into our machines, ensuring they operate at peak efficiency and produce high-quality products.

For instance, our advanced film blowing machines utilize cutting-edge technology to optimize the extrusion process, resulting in consistent film thickness and excellent tensile strength. This not only enhances the quality of the finished product but also reduces material waste, making our machines an eco-friendly choice for manufacturers.

At Kingdom Machinery, we prioritize our customers' needs and satisfaction. Our dedicated support team is available to assist clients throughout the entire process, from selecting the right machinery to providing after-sales service and maintenance.

We believe that strong customer relationships are built on trust and reliability. That's why we offer flexible customization options for our machines, ensuring they fit seamlessly into our clients' production lines. Our timely after-sales service further reinforces our commitment to providing exceptional support.

As a leading manufacturer of plastic bag machinery, we recognize the importance of environmental sustainability. Our machines are designed to minimize energy consumption and reduce waste, aligning with global efforts to promote eco-friendly manufacturing practices.

We also offer a range of recycling machines that facilitate the processing of plastic waste into reusable materials, helping businesses contribute to a circular economy. By choosing our machinery, clients not only improve their production efficiency but also play a vital role in protecting the environment.