Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Blown stretch film machines manufacture oriented, multi-layer polyethylene film designed to combine elasticity, tensile strength, and toughness so packaged loads resist puncture and abrasion under heavy use. This article explains how blown film extrusion and co-extrusion strategies increase puncture resistance, which polymer choices and layer architectures matter most, and how machine technologies translate formulation into consistent, heavy-duty stretch film. Readers will learn practical selection criteria for 3-, 5-, and 7-layer blown films, how advanced screw and die designs plus internal bubble cooling improve gauge uniformity and molecular orientation, and which industrial and agricultural applications benefit most. This hub also supports procurement decisions: Content intent: Information Hub, Lead Generation. Throughout the guide we integrate technical evidence first and then outline how Kingdom Machine Co., Ltd. supports custom blown stretch film production with manufacturing, testing, and service options to help specify the right machine and line configuration.

Blown stretch film machines produce film by extruding molten polymer into a bubble that is biaxially oriented during inflation and take-up, creating improved tear resistance and elasticity compared with many cast processes. The mechanism—melt extrusion, bubble expansion, controlled cooling, and drawdown—aligns polymer chains and increases impact strength and puncture resistance, delivering load retention and puncture tolerance for sharp or irregular loads. In practice, blown stretch film for wrapping heavy pallets combines material selection (LLDPE, metallocene blends), multi-layer architecture, and process control to yield tough packaging film that stretches, recovers, and resists pinholes. The next section explains the core extrusion steps—bubble formation, cooling, and take-up—and how each parameter influences final film properties and puncture performance.

Blown stretch film machines are essential for puncture resistance because they integrate process-induced molecular orientation with flexible material recipes that preserve elasticity and toughness. This combination is particularly effective where load containment and surface protection are critical, and it leads naturally into a closer look at the blown film extrusion mechanism and material choices.

The blown film extrusion process enhances durability by inflating an extruded tubular melt into a controlled bubble that stretches the polymer both circumferentially and longitudinally, improving tensile strength and energy absorption. Key variables—blow-up ratio, die gap, take-up speed, and cooling rate—control molecular orientation and crystallinity, which directly affect puncture resistance and gauge uniformity. For example, slower cooling and optimized take-up produce balanced orientation that resists tear propagation, while precise gauge control reduces weak spots that invite pinholes. Understanding how to tune these parameters helps manufacturers produce consistently tough film for heavy-duty stretch and pallet wrap applications.

Controlling bubble stability and cooling leads to fewer defects and better load-holding performance, which sets the stage for selecting polymers that best exploit those process advantages.

Polymer choice dictates intrinsic film toughness: LLDPE provides excellent toughness and puncture resistance due to its linear structure with short-chain branching, HDPE adds stiffness for dimensional stability, and LDPE contributes processability and cling. Metallocene-catalyzed resins combine clarity with tunable molecular weight distribution, improving both strength and film optics when blended as tie or adhesive layers. Additives and compatibilizers—antioxidants, slip agents, and tie resins—further tailor impact resistance and interlayer adhesion, enabling recycled-content inclusion without sacrificing performance. Selecting the right resin matches desired film attributes—higher LLDPE content for heavy puncture resistance, metallocene blends for clarity plus strength, and HDPE layers when stiffness or barrier rigidity is required.

Material pairing decisions determine whether the film tolerates sharp edges or flexible recovery after impact, and that leads naturally into how multi-layer co-extrusion multiplies these material advantages.

Multi-layer co-extrusion combines distinct polymer layers into a single blown film structure so each layer addresses a specific functional need—core strength, outer abrasion resistance, cling, or barrier—yielding puncture-resistant film with balanced mechanical properties. By distributing stress across layers and using tie layers for adhesion, co-extrusion reduces tear propagation and increases energy absorption at impact points. Layer count is a trade-off between cost and performance: 3-layer lines are efficient and robust for general heavy-duty wrap, while 5- and 7-layer architectures allow recycled content or dedicated barrier/toughness skins. Below is a concise EAV-style comparison of common layer strategies for puncture resistance.

The table demonstrates how co-extrusion architectures allocate functions across layers to improve puncture tolerance and maintain desirable film handling properties.

| Layer Role | Typical Material / Composition | Contribution to Durability |

|---|---|---|

| Outer skin | LLDPE/LDPE blend or metallocene skin | Provides abrasion resistance and controlled cling while resisting micro-tears |

| Core / structural | High-toughness LLDPE or high-MFI metallocene blend | Absorbs impact energy and prevents through-puncture |

| Tie/adhesive | Functionalized polyolefin | Ensures interlayer adhesion and stress transfer between dissimilar polymers |

| Barrier (optional) | EVOH or barrier-modified layer (in some constructions) | Limits gas/moisture permeation where required without compromising puncture strength |

| Recycle/tie layers | Reclaimed polyethylene with compatibilizer | Enables recycled content while preserving cohesion and puncture performance |

This layered approach means manufacturers can specify the roles each polymer plays rather than relying on a single material to deliver every property, and it naturally raises the question of how many layers are optimal for a given application.

Choosing between 3-, 5-, and 7-layer structures balances performance, material flexibility, and cost. Three-layer constructions typically offer a strong core plus skins for abrasion and cling, delivering cost-effective puncture resistance for most pallet wrap uses. Five-layer systems introduce additional functional layers—such as a dedicated tie or recycled-content layer—improving interlayer adhesion and allowing specialized outer skins for UV or anti-scratch properties. Seven-layer lines maximize customization: they can separate barrier, strength, and functional skins to combine recycled content with high-performance outer layers. Each step up in layer count increases tooling and control complexity but yields finer tuning of puncture resistance and other performance metrics.

Choosing the right layer count depends on the application’s need for barrier performance, recycled content, or specialized outer properties, which leads into how layers interact mechanically to resist puncture.

Different polymer layers enhance film strength through load distribution, interfacial adhesion, and complementary deformation behavior under stress. Softer, energy-absorbing outer layers blunt and spread the force of an impacting object, while a tougher core resists penetration and maintains structural integrity. Tie layers chemically bond incompatible polymers, ensuring stress transfers across the stack rather than concentrating at weak interfaces. Properly engineered layer pairings—such as a metallocene skin over an LLDPE core with a functional tie layer—create synergy: the skin shields and the core sustains load, producing a film that resists both puncture and tear propagation. Understanding these interactions helps specify materials and processing to meet target puncture-resistance metrics.

This interlayer synergy points directly to the machine-level technologies needed to realize those performance gains reliably.

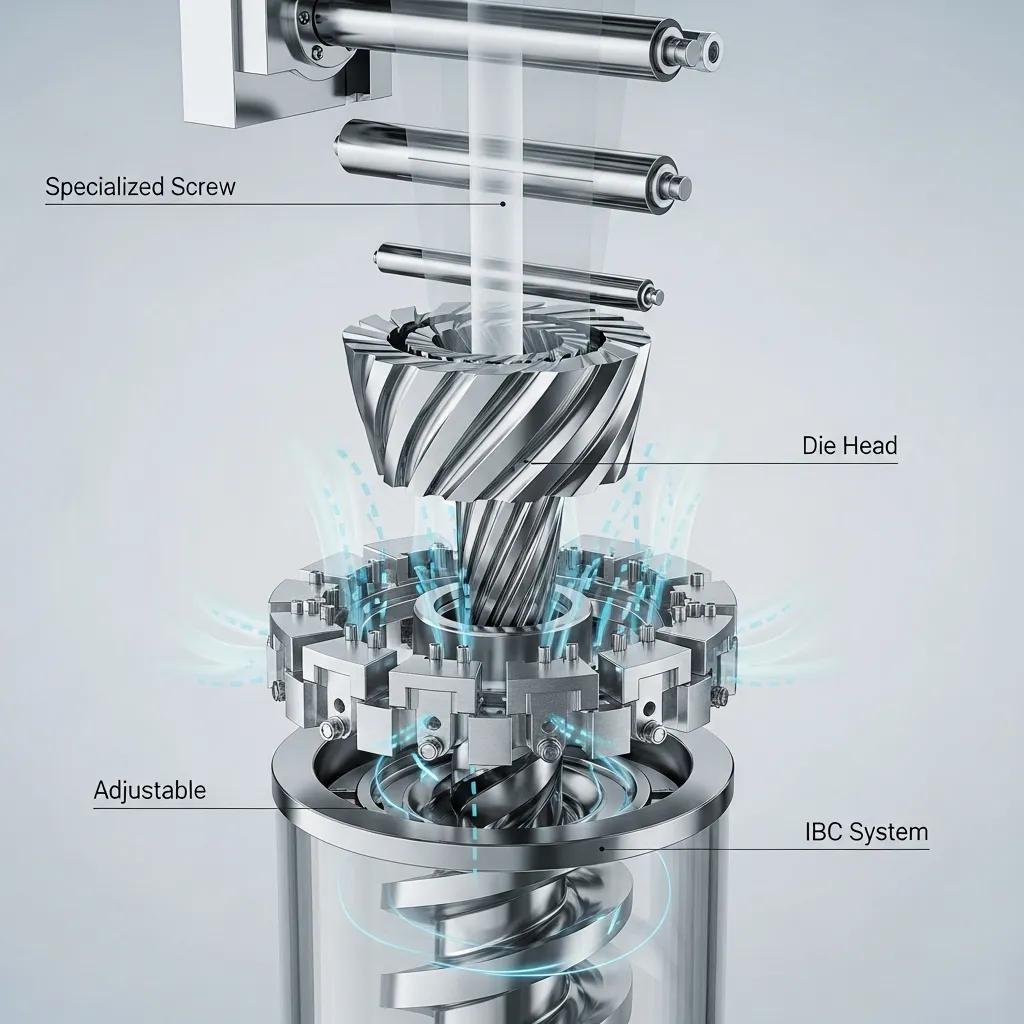

Advanced blown film machines incorporate specialized screws, precision die heads, internal bubble cooling, gravimetric dosing, and PLC process control to convert formulations into uniform, puncture-resistant film. Screw geometry and mixing zones optimize melt homogeneity and degassing, die head design stabilizes the bubble and minimizes shear, and internal bubble cooling (IBC) tightens gauge control and improves molecular orientation for toughness. Process automation—gravimetric feeders and PLC closed-loop control—maintains consistent output and reduces thickness variation that can create weak points. Additionally, energy-saving designs and recycling-friendly extruders enable efficient production of heavy-duty blown stretch film with lower operating costs and environmental impact. The EAV table below maps specific components to film-quality outcomes.

Providing a clear link between machine components and film benefits helps procurement teams evaluate equipment specifications against puncture-resistance goals.

| Machine Component | Technical Attribute | Film Quality Benefit |

|---|---|---|

| Screw (mixing design) | Optimized mixing zones and degassing ports | Homogeneous melt, reduced gel/pinch points, improved tensile strength |

| Die head (annular / adjustable) | Even flow distribution and bubble stability control | Enhanced gauge uniformity and lower pinhole rates |

| Internal Bubble Cooling (IBC) | Controlled internal airflow and temperature control | Better molecular orientation, tighter thickness tolerance, improved tear resistance |

| Gravimetric dosing | Real-time feed accuracy | Consistent composition across runs and reduced material waste |

| PLC closed-loop control | Automated parameter adjustments | Stable process, reproducible mechanical properties, higher uptime |

These component-level advantages explain how process control translates polymer science into tough, reliable film, and they lead naturally to deeper details on screw/die design and IBC operation.

Innovative screw designs optimize melt homogenization and residence time distribution to lower melt temperature variance and eliminate unmelted pockets that become defects in the film. Mixing sections, barrier flights, and venting zones combine to degas and distribute polymer additives evenly, producing a melt that extrudes uniformly through the die head. Die head geometry—gap uniformity, lip design, and flow channel smoothing—determines how evenly material arrives at the air ring; a balanced flow reduces local over- or under-thickness that can compromise puncture resistance. The result is a stable bubble and consistent gauge control, which directly improves film tear resistance and load-holding capacity.

Achieving that uniform melt and flow equilibrium supports the next critical technology: internal bubble cooling.

Internal bubble cooling (IBC) accelerates and evens cooling from within the bubble so the film solidifies with uniform chain orientation and controlled crystallinity, improving tensile strength and puncture resistance. Compared with external-only cooling, IBC reduces temperature gradients across the film thickness and stabilizes the bubble at higher blow-up ratios, enabling greater transverse orientation without sacrificing machine speed. For heavier-gauge, heavy-duty films, tuning IBC airflow and temperature preserves toughness while maintaining capacity, making it easier to produce thicker films that resist puncture. Proper IBC setup complements optimized screw and die systems to deliver both performance and consistent production yields.

IBC’s effect on crystallinity and orientation ties directly to application-specific demands for heavy-duty containment.

Durable blown stretch film is well suited to industrial pallet unitization, protection of irregular or sharp-edged loads, outdoor agricultural uses like silage and greenhouse materials, and specialty packaging where puncture resistance, weatherability, or cling behavior are essential. In industrial logistics, film must secure heavy, stacked loads against shifting, abrasion, and edge damage, while agricultural films require UV resistance and tear robustness for seasonal exposure. Specialty uses include cold-storage palletization where film must tolerate low temperatures without brittle failure. The following list outlines primary applications and why puncture-resistant blown film is chosen for each.

The application mapping clarifies how film properties translate to operational benefits for warehouse, farm, and specialty packaging teams.

These application examples underscore typical selection criteria—tensile strength, puncture resistance, UV stability—that guide film formulation and machine configuration, which we now apply to pallet-specific workflows.

Heavy-duty blown stretch film secures pallets through controlled stretch and elastic recovery that maintain pre-tension and cling over time, distributing containment forces across the load to prevent movement and breakage. For irregular loads with protrusions or sharp edges, thicker outer skins and tougher cores reduce stress concentration and puncture risk, and using films with higher tear resistance ensures that localized damage does not propagate into structural failure. Machine settings—pre-stretch percentage, wrap tension, and film overlap—combine with film selection to create stable unit loads, lowering damage rates and freight claims. Practical workflows match film gauge and layer construction to load profile, balancing material usage against protection needs.

Applying these selection rules reduces load damage and optimizes film cost-per-load, which manufacturers may evaluate against procurement metrics.

Blown film offers weatherability, UV-stabilized formulations, and customizable mechanical profiles that make it ideal for agricultural and specialty packaging where outdoor exposure and mechanical stresses are common. UV additives in skin layers protect against sunlight degradation, while abrasion-resistant outer layers and tough cores resist animal damage and handling wear. Recycled-content options can be integrated via dedicated recycle layers with compatibilizers to preserve durability without forfeiting performance. These customization pathways allow growers and specialty packagers to specify films that meet seasonal durability, clarity, or barrier needs while maintaining puncture and tear resistance.

Matching formulation and layer architecture to field or specialty conditions ensures long-term performance and cost-effective protection for agricultural products and specialty items.

Kingdom Machine Co., Ltd. offers one-stop blown film extrusion solutions focused on simple operation, reliable performance, easy maintenance, and timely after-sales service—attributes highlighted by the company’s information and service positioning. Their lines emphasize energy-saving designs, recycling compatibility, and strong production capacity to support both innovation and mass production. For procurement teams evaluating heavy-duty stretch film extrusion equipment, Kingdom Machine provides customization for layer counts, output capacity, and film width/thickness ranges, supported by experienced R&D engineers and 100 percent final inspection to ensure machines deliver the film properties specified. Below is an EAV table that summarizes key service and feature trade-offs to aid decision-making.

This commercial overview is intentionally concise and supports technical evaluation; for machine selection, teams should match desired film performance to the specifications and services outlined below.

| Service / Feature | Specification / Metric | Business Benefit / Value |

|---|---|---|

| Customization options | 3/5/7-layer configurations; variable widths and microns | Enables tailored film formulations for puncture resistance or recycled content |

| Quality assurance | 100 percent final inspection; R&D support | Reduces commissioning defects and ensures delivered performance |

| After-sales service | Timely technical support and spare parts | Minimizes downtime and preserves ROI |

| Production capacity | Strong manufacturing throughput and fast delivery | Shorter lead times for commissioning and scale-up |

Kingdom Machine’s combination of machine-level features, QA practices, and service supports a smooth transition from pilot formulations to industrial production of puncture-resistant blown stretch film.

Quality assurance for blown stretch film lines centers on factory testing, functional trials, and final inspection to confirm gauge uniformity, film mechanical properties, and process stability before shipment. Kingdom Machine emphasizes 100 percent final inspection and R&D-backed design to catch defects and verify parameter repeatability, while after-sales services include technical training, spare-part provisioning, and responsive maintenance support. These measures help convert technical specifications into predictable on-site performance, reduce startup risk, and shorten time-to-spec production runs. A soft call to action: procurement teams can request machine test protocols and inspection reports to align acceptance criteria with their film performance goals.

Strong QA and responsive after-sales support protect production continuity and ensure film properties meet operational requirements.

Customization options map directly to application requirements: specify 3-layer lines for cost-effective heavy-duty wrap, 5-layer lines when recycled-content or extra functional skins are needed, and 7-layer lines for the highest degree of specialization such as combined barrier and toughness. Typical technical ranges include variable film widths, micron thickness options tailored to application, and process controls like gravimetric dosing and PLC for composition accuracy. By matching layer architecture, resin choices, and machine automation to the customer’s load profiles and throughput targets, Kingdom Machine’s configurations help ensure the chosen line delivers target puncture-resistance, uptime, and return on investment.

A pragmatic selection guide—align desired film performance, recycled-content goals, and throughput needs to the appropriate layer count and control features—simplifies procurement and reduces performance risk.

Content intent: Information Hub, Lead Generation. For specific machine inquiries, Kingdom Machine Co., Ltd. can be contacted by the validated business email and phone in procurement documents; their manufacturing base is located in Ruian Economic Zone, Wenzhou, China 325200.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;

film blown machine, blown film extrusion, plastic bag making machine

At Kingdom Machinery Co., Ltd., we specialize in providing high-quality machinery tailored for the plastic bag and blown film manufacturing industries. Our commitment to excellence ensures that our clients receive reliable and efficient equipment that meets their specific production needs.

With years of experience in the industry, we understand the challenges faced by manufacturers. That's why we offer a range of machines designed to enhance productivity while maintaining top-notch quality. From automatic T-shirt bag making machines to advanced blown film machines, our products are engineered to deliver superior performance and durability.

Our commitment to innovation sets us apart in the plastic machinery industry. We continuously invest in research and development to integrate the latest technology into our machines, ensuring they operate at peak efficiency and produce high-quality products.

For instance, our advanced film blowing machines utilize cutting-edge technology to optimize the extrusion process, resulting in consistent film thickness and excellent tensile strength. This not only enhances the quality of the finished product but also reduces material waste, making our machines an eco-friendly choice for manufacturers.

At Kingdom Machinery, we prioritize our customers' needs and satisfaction. Our dedicated support team is available to assist clients throughout the entire process, from selecting the right machinery to providing after-sales service and maintenance.

We believe that strong customer relationships are built on trust and reliability. That's why we offer flexible customization options for our machines, ensuring they fit seamlessly into our clients' production lines. Our timely after-sales service further reinforces our commitment to providing exceptional support.

As a leading manufacturer of plastic bag machinery, we recognize the importance of environmental sustainability. Our machines are designed to minimize energy consumption and reduce waste, aligning with global efforts to promote eco-friendly manufacturing practices.

We also offer a range of recycling machines that facilitate the processing of plastic waste into reusable materials, helping businesses contribute to a circular economy. By choosing our machinery, clients not only improve their production efficiency but also play a vital role in protecting the environment.