Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Air bubble film, commonly known as bubble wrap, is a two- or multi-layer polyethylene film engineered to trap air in discrete pockets that provide cushioning and impact protection for packed goods. The core production sequence unites extrusion, bubble formation, lamination, and finishing to convert polyethylene resin into continuous air-cushioning rolls suitable for diverse packaging applications. This guide explains the essential raw materials, the step-by-step manufacturing workflow, critical machinery and components, machine types on the market, primary applications and benefits, and sustainability trends shaping the sector. Readers will gain practical production parameters, troubleshooting pointers, and specification tables that aid equipment selection and process tuning. Along the way, the article highlights how material selection and machine configuration influence bubble integrity, film strength, and cost efficiency. Finally, readers will find targeted advice on machine features and vendor capabilities relevant to in-house bubble wrap production and ROI considerations.

Air bubble film manufacturing relies primarily on polyethylene resin grades designed for film extrusion, additives that tune processing and performance, and optionally recycled feedstocks that reduce material cost and environmental impact. Low-density polyethylene (LDPE) is the dominant resin because its molecular branching and melt characteristics produce flexible, sealable films with good bubble formation; typical melt flow index ranges used in bubble film production influence bubble stability and processability. Additives include anti-static agents, UV stabilizers, slip and anti-blocking agents, and colorants; each additive adjusts surface behavior, long-term durability, or handling properties without compromising seal strength. Recycled pellets — from post-industrial or post-consumer sources — are increasingly blended with virgin resin, but require tighter melt index control and filtration to avoid defects in bubble structure. Understanding these material choices informs die design, extrusion temperature profiles, and downstream lamination parameters that preserve cushion performance and throughput.

Polyethylene is a thermoplastic polymer composed of repeating ethylene units; its density and branching determine mechanical and thermal behavior important for film-making. LDPE is preferred for bubble film because its branched structure yields flexibility, good elongation at break, and reliable heat-sealability, which together allow stable bubble formation and secure lamination to a flat film layer. Processing advantages of LDPE include predictable melt behaviour across extruder temperature zones and tolerance for higher shear during screw conveyance, which reduces melt fracture that would harm bubble integrity. Typical property targets for bubble film include moderate tensile strength, high elongation, and a melt flow index selected to balance extrusion throughput and film gauge control. Comparing LDPE to higher-density PEs shows trade-offs where LDPE delivers cushioning and sealability while HDPE favors stiffness and is seldom used alone for bubble film.

Sustainable alternatives such as mechanically recycled LDPE blends, post-consumer recycled (PCR) pellets, and emerging bio-based polyethylenes offer routes to reduce virgin resin use, but each brings processing and quality trade-offs. Recycled LDPE requires rigorous sorting, cleaning, and often filtration systems in the feed to prevent contaminants that can cause pinholes or weak seals in the finished film. Bio-based PE chemically identical to conventional PE can often be processed without major machine changes but may come at higher cost and limited supply; biodegradable polymers are less common due to lower moisture and seal performance in demanding packaging. Adopting recycled or bio-based feedstocks typically requires adjustments to screw design, melt temperature setpoints, and quality-control sampling frequency to maintain bubble geometry and mechanical strength. These operational considerations will directly affect production yield and the downstream finishing process.

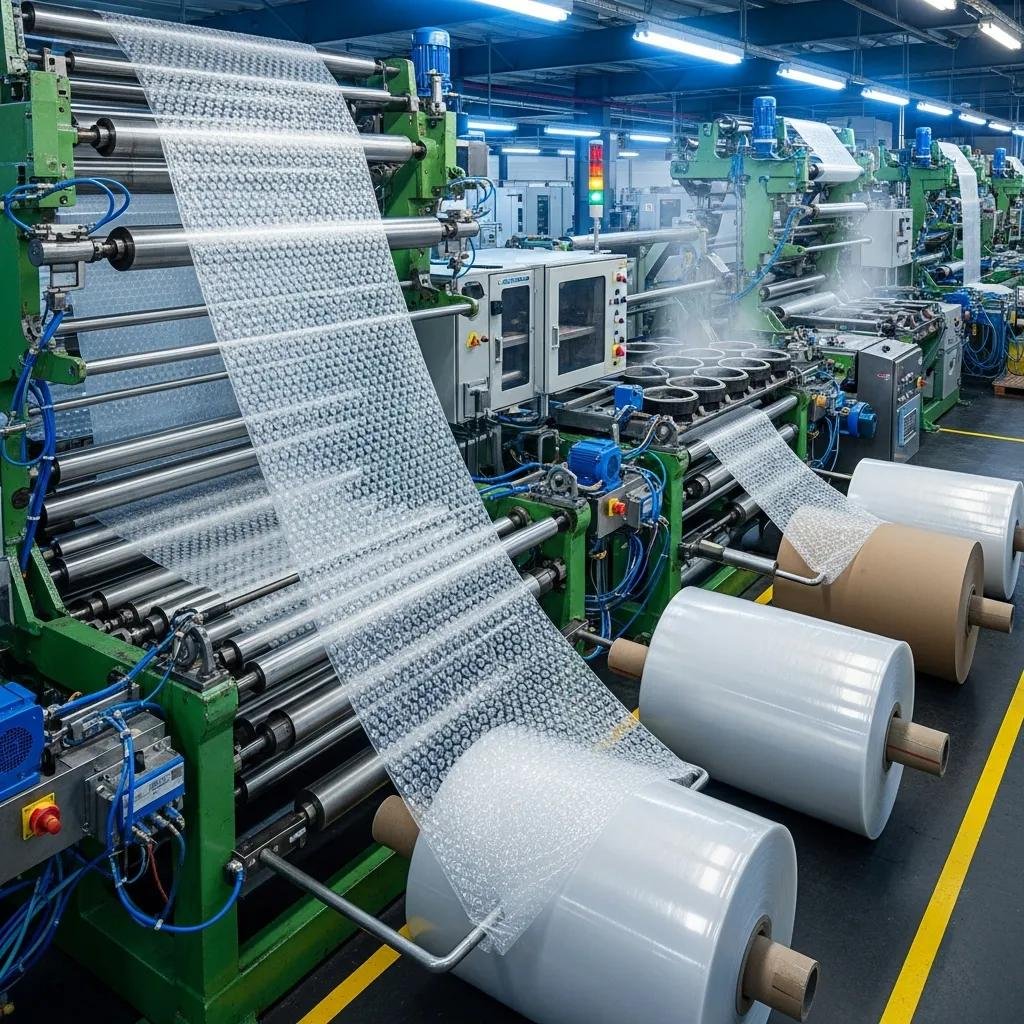

The air bubble film production line converts resin pellets into finished cushioning film through a sequence of coordinated process stages — feeding and extrusion, bubble forming and lamination, cooling and trimming, and slitting/winding — each with specific control parameters to ensure consistent outcomes. Material feeding meters resin into the extruder hopper where a temperature-profiled screw melts and pressurizes the polymer; extrusion through a die head produces a continuous flat film layer that feeds into the bubble former. Bubble formation typically uses a vacuum former drum or patterned former to create discrete pockets, after which a second flat film is laminated over the bubbles using heat and pressure to trap air. Downstream operations include trimming, slitting to width, and winding into rolls with controlled tension and core handling; inline inspection and pressure tests verify bubble integrity and seal quality. Process control variables such as melt temperature, line speed, vacuum level, and nip roll pressure directly influence bubble geometry and production yield.

The production workflow can be summarized in these key steps:

These numbered steps capture the functional flow; the following subsections expand on feeding and extrusion, then bubble forming and lamination in greater detail.

Material feeding begins at the hopper where pellets are metered into the extruder, and drying or storage conditions are managed if recycled or hygroscopic additives are present. Inside the extruder, a segmented screw with tailored geometry generates shear and pressure that melt the polymer and homogenize additives; temperature zones are set to prevent thermal degradation while maintaining sufficient melt strength for bubble formation. Screw design — such as compression ratio and barrier sections — affects throughput, melt homogeneity, and pressure required at the die head; matching screw spec to resin MFI and desired kg/hr throughput reduces surge and film-gauge variation. Practical throughput ranges vary by machine class, but operators tune screw RPM, melt temperature, and downstream line speed while monitoring melt pressure and motor load to stabilize the extrusion process and prevent defects.

Controlling these variables during extrusion sets the stage for reliable bubble formation, so the next section examines how bubbles are formed and sealed.

Bubble formation relies on a forming drum or vacuum former that draws the extruded film into a patterned cavity, creating discrete air pockets whose size and spacing are dictated by the former geometry and line speed. Vacuum levels and the contour of the bubble former control the depth and wall thickness of each pocket; properly tuned nip rollers and lamination temperature ensure the second film layer bonds without collapsing bubbles. Lamination may employ heat and pressure or ultrasonic techniques to secure the seal; critical parameters include lamination temperature, dwell time, and roller pressure to avoid weak seals or trapped volatiles. Bubble geometry — small, medium, or large — affects cushioning performance, with smaller bubbles offering higher point-load protection and larger bubbles delivering superior shock absorption for heavy items.

With bubble creation and lamination defined, we next describe the machines and components that perform these functions on production lines.

A complete bubble film production line comprises multiple interdependent machines: extruders that melt and pressurize resin, die heads that shape the molten film, bubble formers (vacuum drums) that create cavities, rollers and nip units that manage lamination, cooling systems to set film dimensions, and slitting/winding units that finalize roll formats. Control systems such as PLC panels, tension control loops, and motor drives coordinate speed, temperature, and pressure to ensure repeatable film gauge and bubble integrity. Component choices — motor sizing, heater zones, die lip adjustability, and vacuum pump capacity — influence parameters like throughput (kg/hr), line speed (m/min), and achievable film thickness (microns). Well-specified components reduce scrap, simplify maintenance, and expand material handling options when using recycled content or specialty additives.

Below is a concise comparison table of core machinery components and typical performance attributes to help match line components to production needs.

| Component | Key Attribute | Typical Value / Range |

|---|---|---|

| Extruder | Throughput | 150–400 kg/hr |

| Die Head | Adjustable lip width | 300–1200 mm effective width |

| Bubble Former | Vacuum capacity | 0.4–0.8 bar vacuum range |

| Winding Unit | Tension control | Servo-driven tension with PID control |

A bubble film machine follows a start-up sequence that includes pre-heating extruder zones, establishing melt pressure, confirming die flow, and slowly ramping line speed to target while monitoring melt pressure and motor loads. During steady-state production, operators monitor KPIs like m/min line speed, kg/hr throughput, melt pressure, and film thickness uniformity using inline gauges and PLC alarms; process stability is achieved by small adjustments to screw speed, extruder temperature, or nip roller pressure. Shutdown and maintenance procedures include controlled cool-down, cleaning of the die and bubble former, and inspection of wear parts like heater bands and bearings to prolong service life. Operator interfaces (PLC HMI) and safety interlocks simplify control and help maintain consistent quality across shifts.

These operational behaviors connect directly to component roles, which are described next.

The extruder is responsible for melting resin and providing the pressure and flow necessary for a stable film mass, with screw geometry and motor torque determining throughput and melt homogeneity. The die head shapes the molten film profile and sets the initial film thickness; adjustable die lips and flow channels are essential for fine-tuning gauge and preventing lip drool or thin spots. Rollers — including chill rolls, nip rollers, and lamination rolls — control film cooling, bubble formation engagement, and the heat/pressure needed for lamination, directly affecting bubble integrity and dimensional accuracy. Regular maintenance of wear parts such as die lips and roller bearings, plus monitoring for common failure modes like air leakage in vacuum systems or heater element drift, preserves uptime and film quality.

To help buyers compare components by specification, the following table maps entities to attributes and typical values.

| Machine Element | Attribute | Typical Specification |

|---|---|---|

| Extruder | Motor power | 30–120 kW |

| Die Head | Lip adjustability | ± 0.05 mm control |

| Bubble Former | Diameter | 400–1,200 mm |

| Slitting Unit | Knife types | Rotary or razor slitting |

Kingdom Machine Co., Ltd. manufactures a range of bubble film machines including 2-layer, 3-layer, and multi-layer co-extrusion lines tailored for different production scales and product performance requirements. Their equipment portfolio supports automatic cutting and winding options, and machines are configurable to handle virgin LDPE and recycled pellets with appropriate feeding and filtration setups. Kingdom Machine Co., Ltd.’s factual selling points include: Simple operation and perfect performance; easy maintenance and timely after-sales service; quality assurance with 100 percent final inspection during production and defective rate controlled between 1% and 3%; two-year warranty on timer switches; strong R&D team and production capacity (16 production lines, internal R&D lab with 30+ testing equipment); one-stop service with customization options; competitive prices via large-scale production and trained workers; fast delivery (samples within 3 days, bulk 15-20 days, standard machines 25-30 days); global reach with over 1,700 machines installed worldwide in 102 countries since 2005. Prospective buyers seeking material-handling configurations or quotes are encouraged to contact Kingdom Machine Co., Ltd. to discuss machine models and customization.

For quick comparison, the table below summarizes typical machine types, primary features, and recommended use-cases for selection.

| Machine Type | Feature | Recommended Use-Case |

|---|---|---|

| 2-Layer Machine | Simpler design, lower material usage | Cost-sensitive cushioning for light-duty shipments |

| 3-Layer Machine | Improved mechanical properties | Higher-performance cushioning and barrier options |

| Multi-Layer Co-extrusion | Customized layer functions | Specialty films with recycled content or barrier layers |

Two-layer machines extrude a single bubble layer laminated to a flat web and are valued for simplicity, lower capital cost, and easy maintenance, making them suitable for straightforward cushioning applications. Three-layer machines add an intermediate or skin layer that improves mechanical strength, permits different material blends, and supports enhanced barrier or sealing performance when required. Multi-layer co-extrusion lines enable complex layer architectures that combine virgin and recycled resins, integrate barrier additives, or tune outer-surface properties for slip and printability, but they increase process complexity and equipment cost. Selecting among these options balances cost-per-roll, desired protective performance, and flexibility for future product variants.

Automatic cutting units integrated with PLC control deliver consistent cut lengths, reduce manual handling, and minimize variability in finished roll formats, improving throughput and lowering labor requirements. Precision cutting reduces waste from irregular edges and speeds packaging downstream, while integration with winding and slitting units eliminates handoffs that can cause downtime. Measurable benefits include reduced changeover time between roll sizes, fewer operator interventions, and improved yield consistency; these gains are especially valuable in high-mix production environments or when supplying diverse roll sizes to e-commerce clients. Automated systems also support repeatable quality control, enabling tighter tolerances on roll length and edge finish.

Air bubble film provides versatile protective packaging solutions across many industries by offering high cushioning-to-weight ratio, ease of use, and adaptability to custom roll formats, which together lower shipping damage rates and logistic costs. Primary application areas include e-commerce parcel cushioning, electronics protection (with anti-static variants), pharmaceutical inner packaging requiring cleanliness controls, and industrial parts protection during transport. Benefits include lightweight protection that reduces freight expense, void filling and surface protection that minimize product returns, and the ability to combine bubble films with adhesive or printed layers for branding or instruction. The following list highlights core advantages manufacturers and packers typically cite when choosing bubble film.

In e-commerce, bubble film is often supplied in multiple roll widths and bubble sizes to accommodate diverse SKU profiles, enabling packers to tailor cushioning to each shipment and reduce oversized packaging. Electronics manufacturers and assemblers prefer anti-static bubble films and smaller-bubble formats to protect circuit boards and components from mechanical shock and electrostatic discharge. Pharmaceutical packagers require validated materials and clean handling — bubble film for this sector is often specified with controlled additives and handling protocols to meet regulatory expectations. Customization options such as printed instructions or tamper-evident layers add further value for regulated industries.

In-house bubble wrap production gives businesses control over lead times, customization, and long-term packaging costs by producing rolls sized for specific products, printing branding or instructions inline, and adjusting bubble geometry for unique protection needs. The ROI for in-house production typically depends on packaging volume, product fragility, and SKU mix; companies with stable, high-volume packing operations can realize lower per-unit costs and reduced dependency on external suppliers. Additional advantages include immediate response to material shortages, the ability to trial new film formulations rapidly, and capture of value from recycling programs when recycled feedstocks are reprocessed onsite. For businesses evaluating this investment, machine selection should factor in production flexibility, automation features, and anticipated material blends to ensure cost-effectiveness.

Sustainability trends are driving adoption of recycled content, energy-efficient motors and drives, and designs that simplify recycling at end-of-life, all of which influence machine specifications and process controls. Mechanically recycled LDPE blends and PCR content are the most immediate options for reducing virgin resin use, but they require optimized feeding, filtration, and melt-control systems to avoid defects. Energy-efficient components such as high-efficiency motors, variable-frequency drives, and improved insulation on heaters reduce operational power consumption and operating costs. Market and regulatory drivers increasingly favour recyclable mono-material designs and documented recycled content levels, prompting line upgrades and supplier verification processes.

Emerging eco-friendly options include higher-percentage PCR LDPE blends, chemically recycled resins that restore feedstock quality, and bio-based polyethylene equivalents that can be processed like conventional PE. Each approach has implications for processing: PCR requires robust contamination control and narrower MFI ranges; chemically recycled resins are closer to virgin quality but currently have limited commercial availability; bio-based options may depend on feedstock sourcing and certification. Process-wise, closed-loop systems that reclaim trim and rejects and refeed them after granulation can improve material-efficiency, but they necessitate additional extrusion cleaning and quality checks to maintain bubble integrity. Manufacturers weighing these options must consider supply chain availability, certification needs, and required machine adaptations.

Energy-efficient machines reduce operating costs through lower motor and heater demand and often include advanced control algorithms that minimize idle power consumption without sacrificing production speed. Introducing recycled content can reduce material cost and embodied carbon but often reduces melt strength or introduces variability, so processors compensate with modified screw profiles, tighter temperature control, and enhanced filtration to maintain bubble quality. Quality-control steps such as increased sampling frequency, inline thickness gauging, and pressure-hold testing ensure consistent bubble integrity when feedstock variability increases. Thoughtful integration of energy-efficient hardware and process tuning enables manufacturers to meet sustainability goals while preserving throughput and product performance.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;

film blown machine, blown film extrusion, plastic bag making machine

At Kingdom Machinery Co., Ltd., we specialize in providing high-quality machinery tailored for the plastic bag and blown film manufacturing industries. Our commitment to excellence ensures that our clients receive reliable and efficient equipment that meets their specific production needs.

With years of experience in the industry, we understand the challenges faced by manufacturers. That's why we offer a range of machines designed to enhance productivity while maintaining top-notch quality. From automatic T-shirt bag making machines to advanced blown film machines, our products are engineered to deliver superior performance and durability.

Our commitment to innovation sets us apart in the plastic machinery industry. We continuously invest in research and development to integrate the latest technology into our machines, ensuring they operate at peak efficiency and produce high-quality products.

For instance, our advanced film blowing machines utilize cutting-edge technology to optimize the extrusion process, resulting in consistent film thickness and excellent tensile strength. This not only enhances the quality of the finished product but also reduces material waste, making our machines an eco-friendly choice for manufacturers.

At Kingdom Machinery, we prioritize our customers' needs and satisfaction. Our dedicated support team is available to assist clients throughout the entire process, from selecting the right machinery to providing after-sales service and maintenance.

We believe that strong customer relationships are built on trust and reliability. That's why we offer flexible customization options for our machines, ensuring they fit seamlessly into our clients' production lines. Our timely after-sales service further reinforces our commitment to providing exceptional support.

As a leading manufacturer of plastic bag machinery, we recognize the importance of environmental sustainability. Our machines are designed to minimize energy consumption and reduce waste, aligning with global efforts to promote eco-friendly manufacturing practices.

We also offer a range of recycling machines that facilitate the processing of plastic waste into reusable materials, helping businesses contribute to a circular economy. By choosing our machinery, clients not only improve their production efficiency but also play a vital role in protecting the environment.