Customizable Shopping Bag Solutions for Retailers

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

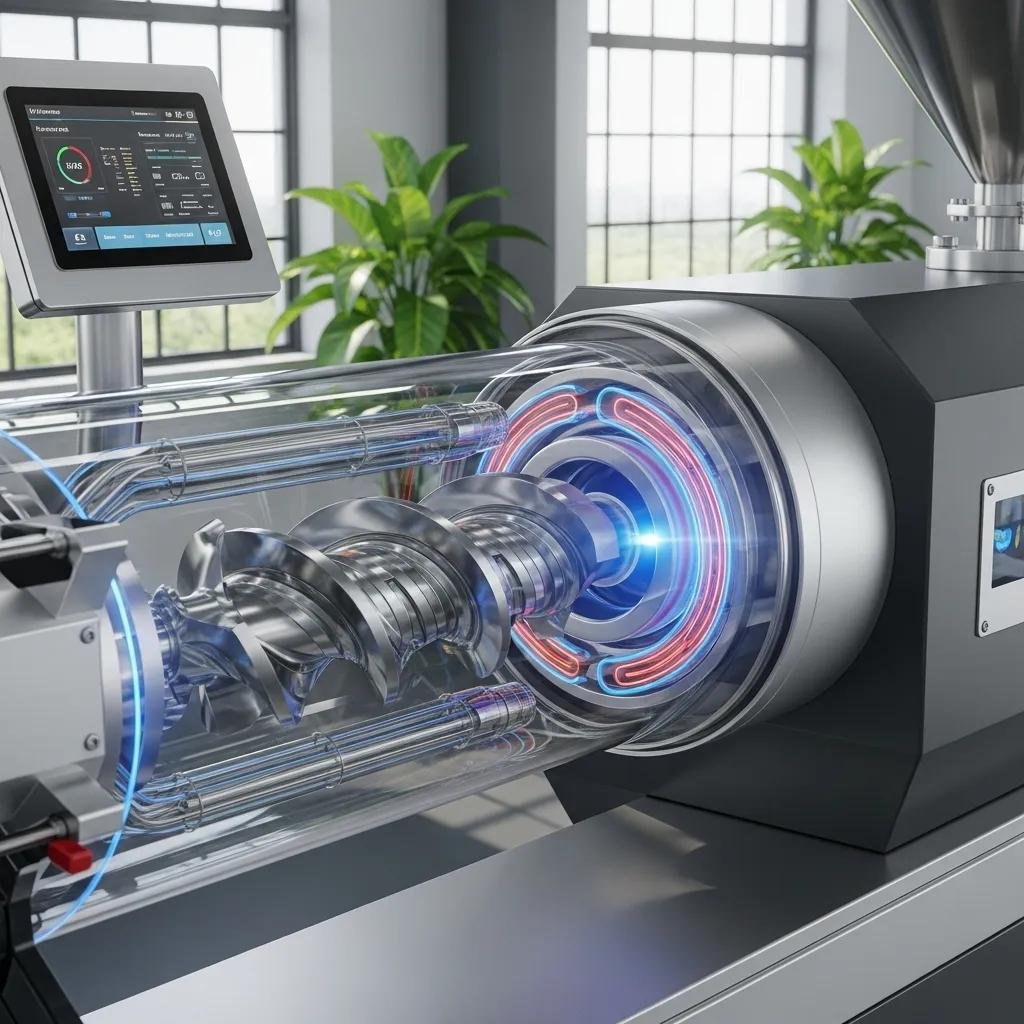

Screw geometry plays a pivotal role in the efficiency and quality of plastic extrusion processes. Understanding the intricacies of screw design can significantly enhance production outcomes, leading to improved melt homogeneity, energy efficiency, and product quality. This article delves into the fundamental principles of screw geometry, exploring how various parameters influence plasticizing efficiency and overall extrusion performance. Many manufacturers face challenges in achieving consistent product quality and operational efficiency, which can be addressed through optimized screw designs. This guide will cover the essential aspects of screw geometry, including the impact of the L/D ratio, compression ratio, mixing sections, and the differences between single and twin screw extruders.

Extruder screw geometry refers to the design and configuration of the screw used in plastic extrusion, which is crucial for determining the performance of the extrusion process. Key principles include the length-to-diameter (L/D) ratio and the compression ratio, both of which significantly affect melting efficiency and pressure build-up within the extruder. Understanding these principles allows manufacturers to optimize their processes for better output and quality.

The L/D ratio is a critical factor in screw design, representing the length of the screw relative to its diameter. A higher L/D ratio typically enhances the melting and mixing of polymers, leading to improved material processing. For instance, an L/D ratio of 24:1 to 30:1 is often optimal for many thermoplastics, facilitating better heat transfer and material flow. This configuration allows for more efficient melting and reduces the risk of thermal degradation, ultimately improving the quality of the extruded product.

The compression ratio, defined as the ratio of the channel depth in the feed section to that in the metering section of the screw, plays a vital role in the melting process. A higher compression ratio can lead to increased pressure build-up, which is essential for effective melting and homogenization of the polymer. However, excessive compression can cause shear heating, leading to thermal degradation. Therefore, selecting the appropriate compression ratio is crucial for balancing melting efficiency and maintaining product integrity.

Mixing sections and flight geometry are integral to achieving uniform melt homogeneity in plastic extrusion. The design of these components influences how well the polymer is mixed and heated, which directly impacts the quality of the final product.

Mixing elements, such as kneading blocks and dispersive mixers, enhance the dispersion of additives and fillers within the polymer matrix. These elements create shear forces that promote thorough mixing, resulting in a more homogeneous melt. Effective mixing is essential for producing high-quality extruded products, as it ensures that all components are evenly distributed throughout the material.

The flight depth and pitch of the screw affect the transport of materials through the extruder. A deeper flight can increase the volume of material transported, while the pitch influences the rate of material movement. Optimizing these parameters is crucial for maintaining consistent material flow and preventing bottlenecks in the extrusion process. Properly designed flight geometry can enhance the efficiency of material transport, leading to improved production rates and product quality.

Optimizing screw parameters is essential for enhancing plasticizing efficiency in blown film extrusion. Key factors include the design of the screw, the choice of materials, and the operational settings of the extruder.

Screw design significantly impacts the consistency of film thickness in blown film extrusion. A well-designed screw ensures uniform melting and mixing, which is critical for producing films with consistent thickness. Variations in screw geometry can lead to fluctuations in melt flow, resulting in uneven film thickness. Manufacturers must carefully consider screw design to achieve the desired film quality and performance.

Screw geometry also influences energy consumption and throughput in the extrusion process. An optimized screw design can reduce energy requirements by improving the efficiency of melting and material transport. For example, a screw with an appropriate compression ratio may require less energy to achieve the same throughput, making it a more sustainable option for manufacturers. Understanding these dynamics allows for better energy management and cost savings in production.

Advanced screw geometry is designed to minimize thermal degradation and enhance the quality of extruded products. By optimizing the design of the screw, manufacturers can achieve better control over the melting process and reduce the risk of material degradation.

Features such as barrier screws and specially designed mixing elements can significantly reduce residence time and shear heating. These designs allow for more efficient melting and mixing, minimizing the exposure of the polymer to high temperatures. As a result, the risk of thermal degradation is reduced, leading to higher-quality extruded products.

Optimized screw geometry contributes to enhanced melt temperature uniformity by ensuring consistent heat distribution throughout the melt. This uniformity is crucial for achieving high-quality extruded products, as temperature variations can lead to defects and inconsistencies. By employing advanced screw designs, manufacturers can improve melt temperature control, resulting in better product quality and performance.

Single and twin screw extruders serve different purposes in polymer processing, each with its unique advantages and applications. Understanding these differences is essential for selecting the appropriate extruder for specific materials and processes.

Single screw extruders are often preferred for processing materials that require less intensive mixing and lower shear rates. They are ideal for applications involving homopolymers and certain thermoplastics, where consistent melt quality is essential. The simplicity of single screw designs also makes them a cost-effective choice for many manufacturers.

Twin screw extruders provide enhanced mixing capabilities and versatility, making them suitable for a broader range of materials and applications. The intermeshing design of twin screws allows for better material dispersion and more efficient processing of complex formulations, including those with additives and fillers. This versatility makes twin screw extruders a popular choice for advanced polymer processing applications.

Energy-efficient screw designs play a crucial role in promoting sustainability in plastic extrusion. By optimizing energy consumption, manufacturers can reduce their environmental impact while maintaining high production standards.

Recent innovations in screw geometry, such as the development of energy-efficient designs and materials, have significantly reduced power consumption in extrusion processes. These advancements allow for lower energy requirements while maintaining optimal performance, contributing to more sustainable manufacturing practices.

Screw design is critical for effectively processing recycled post-consumer recycled (PCR) materials. Advanced screw geometries can accommodate the unique properties of recycled materials, ensuring consistent melting and mixing. This capability is essential for integrating recycled content into new products, supporting the circular economy and reducing reliance on virgin materials.

| Screw Parameter | Impact on Efficiency | Optimal Range |

|---|---|---|

| L/D Ratio | Affects melting and mixing | 24:1 – 30:1 |

| Compression Ratio | Influences pressure build-up | 2:1 – 4:1 |

| Flight Depth | Impacts material transport | Approximately 1/3 to 1/2 of diameter |

In conclusion, understanding the role of screw geometry in plastic extrusion is essential for manufacturers aiming to enhance efficiency and product quality. By optimizing screw design parameters, companies can achieve better melt homogeneity, reduce energy consumption, and improve the processing of recycled materials. As the industry continues to evolve, advancements in screw geometry will play a pivotal role in driving sustainable practices and meeting the demands of modern plastic processing.

Elevate your brand with customizable shopping bag solutions. Our retail plastic bags enhance your packaging strategy while meeting diverse business needs.

Learn about effective plastic recycling strategies implemented across Europe. Join the movement towards sustainability and reduce environmental impact today.

Learn how to effectively launch a high-volume bag production facility with our detailed case study. Optimize operations and maximize returns today!

Elevate your food safety with innovative plastic packaging. Our food-grade bags and films enhance freshness, ensuring quality and longevity in every bite.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;

film blown machine, blown film extrusion, plastic bag making machine

At Kingdom Machinery Co., Ltd., we specialize in providing high-quality machinery tailored for the plastic bag and blown film manufacturing industries. Our commitment to excellence ensures that our clients receive reliable and efficient equipment that meets their specific production needs.

With years of experience in the industry, we understand the challenges faced by manufacturers. That's why we offer a range of machines designed to enhance productivity while maintaining top-notch quality. From automatic T-shirt bag making machines to advanced blown film machines, our products are engineered to deliver superior performance and durability.

Our commitment to innovation sets us apart in the plastic machinery industry. We continuously invest in research and development to integrate the latest technology into our machines, ensuring they operate at peak efficiency and produce high-quality products.

For instance, our advanced film blowing machines utilize cutting-edge technology to optimize the extrusion process, resulting in consistent film thickness and excellent tensile strength. This not only enhances the quality of the finished product but also reduces material waste, making our machines an eco-friendly choice for manufacturers.

At Kingdom Machinery, we prioritize our customers' needs and satisfaction. Our dedicated support team is available to assist clients throughout the entire process, from selecting the right machinery to providing after-sales service and maintenance.

We believe that strong customer relationships are built on trust and reliability. That's why we offer flexible customization options for our machines, ensuring they fit seamlessly into our clients' production lines. Our timely after-sales service further reinforces our commitment to providing exceptional support.

As a leading manufacturer of plastic bag machinery, we recognize the importance of environmental sustainability. Our machines are designed to minimize energy consumption and reduce waste, aligning with global efforts to promote eco-friendly manufacturing practices.

We also offer a range of recycling machines that facilitate the processing of plastic waste into reusable materials, helping businesses contribute to a circular economy. By choosing our machinery, clients not only improve their production efficiency but also play a vital role in protecting the environment.