Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Advanced flexo printing machines combine precision mechanics, modern drive systems, and automated controls to deliver high-quality graphics on flexible packaging substrates, improving yield and reducing waste for manufacturers. This guide explains what makes a flexographic press “advanced” — including central impression (CI) architecture, gearless servo drives, automated registration, and ink system compatibility — and shows how these technologies translate into measurable production benefits. Readers will learn how CI flexo improves registration for film, why gearless servo systems enhance print stability and changeover speed, how high-speed flexo increases throughput, and which sustainability levers reduce VOCs and energy use. The article maps core machine features, throughput calculations, maintenance best practices, and industry-specific applications to help procurement teams and production managers choose the right equipment. Each section includes practical lists, specification tables, and examples that clarify trade-offs between speed, substrate handling, and print quality to support purchasing and operational decisions. Deploying these insights leads naturally into vendor selection and customization considerations, which are addressed in the integration notes following the technical sections.

Advanced flexo printing machines are flexographic printing presses engineered for precise, repeatable printing on flexible substrates by integrating gearless servo drives, optional CI layouts, and enhanced web handling systems to minimize registration error and material waste. These machines combine anilox metering, controlled impression cylinders, and drying systems with automated job recall and web guides to maintain consistent ink transfer and alignment, which directly improves color fidelity and first-pass yield. The primary value is reduced downtime and scrap through accurate registration and faster changeovers, enabling both short runs with frequent SKUs and long runs with stable output. Below is a concise list of defining technical features to consider when evaluating equipment for film and bag production.

Advanced flexo presses typically include these core features:

These differentiated features lead naturally to machine class comparisons that help buyers match capacity and capabilities to production needs, which the following table summarizes before we examine detailed component impacts.

Different machine classes prioritize features differently depending on production goals.

| Model Class | Drive System | Typical Advantage |

|---|---|---|

| Entry / Standard | Geared or basic servo | Lower capital cost, suitable for simple label and bag jobs |

| Mid-range | Gearless servo (single motor per station) | Improved registration, faster changeovers, suitable for mixed runs |

| Advanced / CI-capable | Gearless servo + Central Impression | Best for high-quality film printing, edge-to-edge graphics, repeatable multi-color runs |

This comparison clarifies how drive architecture and CI availability differentiate model classes, helping buyers balance upfront cost against production benefits. Understanding these distinctions prepares us to analyze how specific components like gearless servo drives directly influence performance.

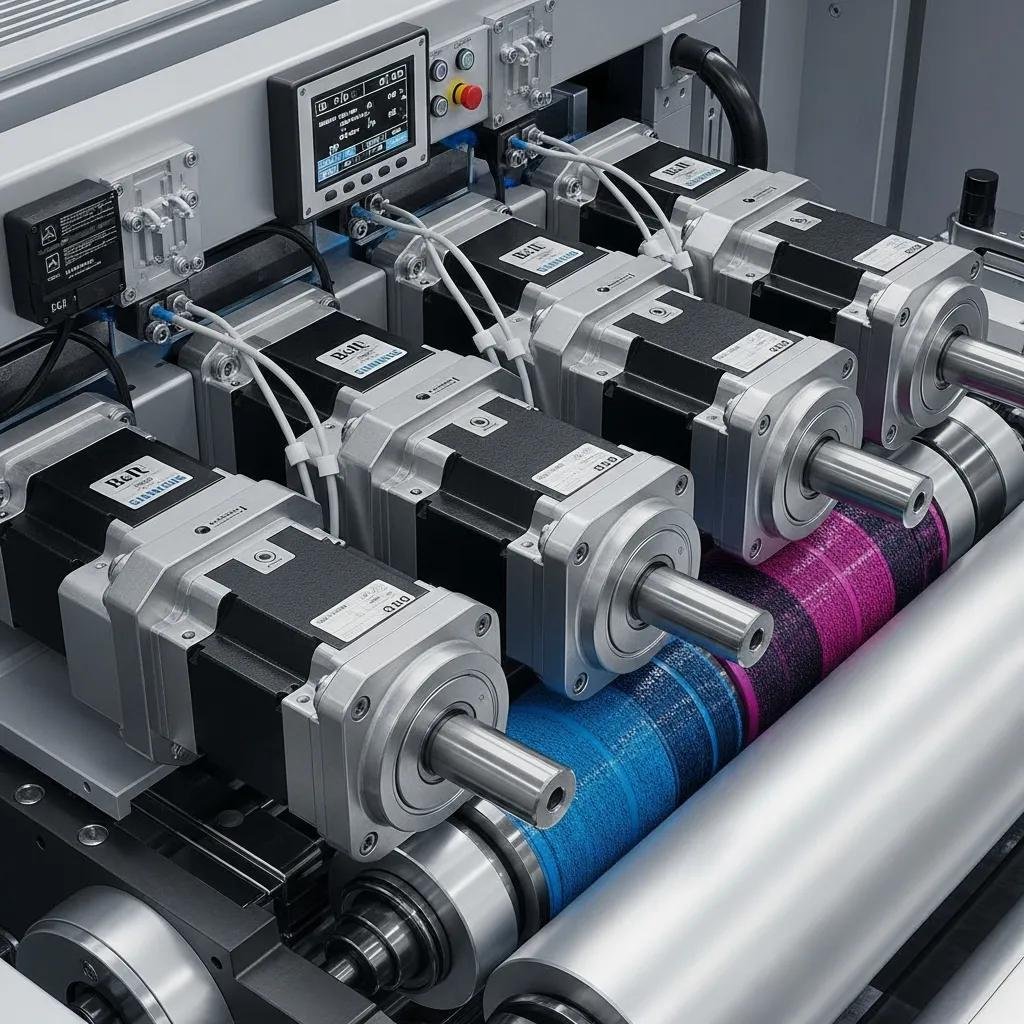

Gearless servo drives replace traditional mechanical gear trains with individual servo motors controlling each print station, which reduces mechanical backlash and vibration while delivering immediate, programmable torque control. The elimination of gear mesh means less periodic maintenance and finer micro-adjustments to registration, resulting in registration tolerances that can improve by measurable increments, often down to sub-0.1 mm under controlled conditions. Operationally, gearless systems enable faster job changeovers through software-based plate positioning and memory recall, reducing setup time between SKUs and increasing effective run time. The combination of reduced mechanical wear and precise electronic control also lowers long-term maintenance costs and supports remote diagnostics, which smoothly leads into how automation modules further improve overall press efficiency.

Automation features in modern flexo machines include auto-registration systems, job memory with recipe recall, automated web splicing, remote monitoring, and integrated HMI panels that centralize control and diagnostics for the entire press. Auto-registration uses closed-loop feedback from sensors or camera inspection systems to adjust servo positions in real time, reducing make-ready time and improving repeatability across runs. Job memory stores settings for tension profiles, plate positions, ink curves, dryer settings, and web paths so repeat jobs start with predictable quality and minimal operator intervention. These automation modules reduce waste during setup and enable leaner staffing, and they integrate with predictive maintenance systems to flag component wear before failures occur, which prepares us to consider vendor capabilities that support these advanced features.

For buyers comparing automation levels, these modules are particularly important:

These automation elements complement mechanical improvements like gearless drives and CI design, and they highlight where supplier support and after-sales service materially affect long-term performance.

After evaluating core technologies and automation benefits, manufacturers often request vendor-specific details about available models and lead times. Kingdom Machine Co., Ltd. / China Evergreen Machinery Co., Ltd. is positioned as a supplier of relevant equipment, offering blown film, bag making, and flexible printing machines alongside extensive production and inspection processes. The company emphasizes one-stop customization from prototype to mass production, conducts 100 percent final inspection during production, and provides an R&D laboratory with multiple testing instruments to validate machine performance before delivery. These vendor capabilities support rapid sample delivery and predictable bulk lead times, and procurement teams frequently contact suppliers to request model specifications or quotes when CI and gearless options are priorities.

CI flexo, or central impression flexography, uses a single large impression cylinder that supports the web through multiple print stations, providing continuous and uniform support of the substrate during ink transfer which improves registration and reduces handling-induced distortion. The CI architecture minimizes cumulative web deviations because the film remains wrapped around a single reference cylinder during successive color passes, which directly reduces banding and improves multi-color alignment on stretchable or thin films. In practice, CI designs yield better edge-to-edge coverage and more consistent print density, enhancing perceived brand quality on pouches and film packaging. The following subsections explain why mechanical CI design matters and list CI advantages for high-quality film printing.

Central impression design provides mechanical stability by maintaining the web under constant impression on a single reference cylinder, which lowers the number of web handling events and decreases the chance of registration drift across color stations. This single-impression approach yields tighter registration tolerances, often enabling multi-color alignment within narrow margins that are essential for high-resolution graphics and small type on flexible films. For thin, elastic, or highly stretched substrates like LDPE and CPP, CI reduces substrate movement during printing and is therefore preferred when precise color-to-color registration is required. The mechanical stability of CI feeds directly into cleaner make-ready cycles and higher first-pass yield, which naturally leads into the practical advantages CI offers for different packaging formats.

CI flexo delivers several practical advantages: improved color consistency across long runs, higher repeatability between jobs, lower scrap rates from misregistration, and easier multi-color layouts that would be difficult on open-stack presses. These benefits make CI well-suited for snack pouches, multi-color laminated films, and shrink-wraps where visual appeal and brand fidelity matter. With reduced rework and improved first-pass yields, CI presses often justify their higher capital cost through lower operating waste and less manual intervention. Understanding these advantages helps procurement teams prioritize CI when their product mix or brand requirements demand edge-to-edge, multi-color printing, and it sets the stage for throughput considerations where speed and substrate type play critical roles.

After reviewing CI benefits, many buyers seek supplier examples of CI-capable models and customization options. Kingdom Machine Co., Ltd. / China Evergreen Machinery Co., Ltd. lists CI flexo among their flexible printing offerings and supports customization from prototype to mass production, backed by an experienced R&D and engineering team. Prospective customers commonly request model brochures and performance data to validate registration tolerances and to align machine specs with specific film substrates before committing to purchase.

High-speed flexo printing equipment increases production capacity by raising web speed and enabling wider web widths or adding more colors per pass, which reduces cost per unit through higher throughput and improved equipment utilization. The net effect is faster cycle times and lower per-unit labor and overhead, provided supporting systems such as drying, unwind/rewind, and chill rolls are adequately sized to manage heat and dimensional stability. Trade-offs include more stringent substrate handling requirements and tighter process control to maintain print quality at speed, so production lines must balance speed with inspection and inline quality controls. Below is a list of primary economic and operational benefits of high-speed flexo presses.

Key benefits of high-speed flexo include:

To quantify throughput and support purchasing decisions, the table below demonstrates how web speed correlates with output estimates for film production and helps model ROI for potential investments.

| Throughput Metric | Web Speed (m/min) | Output Estimate (kg/day) |

|---|---|---|

| Moderate speed | 150 | 1,200–1,800 |

| High speed | 300 | 2,400–3,600 |

| Ultra-high speed | 450 | 3,600–5,400 |

These example metrics illustrate how doubling web speed can roughly double output, assuming substrate and drying systems scale accordingly, and they emphasize the need for integrated supporting systems to maintain quality as speed increases.

High-speed printing increases production capacity by reducing cycle times per meter of film so more material is processed in the same shift length, while wider web formats and multi-color inline stations increase the effective surface area printed per pass. Crucially, drying capacity and cooling systems must match higher speeds to avoid ink set and film deformation; otherwise, throughput gains will be offset by defects and rework. Inline inspection and automatic reject systems become essential at speed to catch defects without halting production, and these systems feed into predictive maintenance models to preserve uptime. Properly engineered, high-speed flexo lines deliver both volume and consistent quality for commodity and branded film runs, which transitions to the question of which substrates are compatible at different speeds.

Advanced flexo printers handle common substrates such as LDPE, HDPE, BOPP, BOPET, CPP, and laminated multi-layer films; each substrate presents distinct handling needs based on stretch, heat sensitivity, and surface energy. For example, BOPP and BOPET are dimensionally stable and perform well at higher speeds with proper corona treatment, while LDPE and CPP require more careful tension control due to higher elasticity. Substrate selection influences recommended machine features: CI and gearless servo options improve performance on elastic films, whereas solventless or water-based ink systems affect drying requirements and energy use. Matching machine capabilities to substrate properties ensures reliable print quality and lower waste, and this compatibility consideration ties into sustainability choices for inks and energy systems.

Sustainable flexo printing solutions reduce environmental impact by employing water-based inks, solventless processes, energy-efficient drives, and integration with recycling workflows to lower VOC emissions, energy consumption, and material waste across production cycles. Water-based inks substantially lower VOC output compared with solvent-based systems, while energy-efficient gearless servo drives and optimized dryer designs cut electricity usage during runs. Recycling integration—such as reclaiming trim, reprocessing film waste, and coordinating with upstream recycling machines—further reduces raw material costs and supports circularity for packaging lines. The table below compares common ink and system choices on key sustainability metrics to inform procurement prioritization.

| Technology | Primary Environmental Metric | Operational Impact |

|---|---|---|

| Water-based inks | Low VOC emissions | May require higher drying energy, substrate-specific formulation |

| Solventless systems | Near-zero solvent use | Reduces VOCs and simplifies regulatory compliance |

| Energy-efficient drives | Reduced kWh per output | Lowers operational cost and carbon footprint |

The comparison shows how combining low-VOC inks with energy-efficient mechanical systems delivers a net environmental benefit, and it prepares operators to assess conversion costs and ROI when shifting to greener workflows.

Water-based inks reduce volatile organic compound emissions and often simplify regulatory compliance in regions with strict VOC limits, while energy-efficient drive systems and modern dryer designs cut power consumption per produced meter of film. Transitioning from solvent-based to water-based inks may require substrate testing, modified anilox selection, and dryer reconfiguration to maintain print finish and adhesion on hydrophobic films. Energy-efficient gearless servo drives provide precise control that can reduce waste and shorten make-ready cycles, which offsets conversion costs. Considering both ink chemistry and drive/dryer efficiency together yields the most practical sustainability gains and sets the stage for integrating recycling equipment with printing operations.

Recycling machines integrate with flexo printing processes by handling post-production trimmings, off-spec reels, and process scrap to produce regrind or pellets that can re-enter the film extrusion or lamination line under controlled formulations. Typical integration points include dedicated scrap collection at rewind stations, conveyor-fed flake systems feeding pelletizers, and quality-sorting steps to minimize contamination that would degrade recycled material value. Integrating recycling reduces material costs and landfill waste, but requires careful contamination control and compatibility checks to maintain final film properties. When recycling is part of the production flow, coordination between printing, converting, and extrusion teams helps preserve material quality and supports circular packaging strategies.

Effective maintenance for flexographic printing machines combines daily cleaning routines, scheduled lubrication and alignment checks, anilox roll care, and a spare parts strategy to minimize downtime and extend machine lifespan. Preventative maintenance reduces unexpected failures and keeps print quality within specification by preserving component tolerances and detecting wear early. A documented schedule that breaks tasks into daily, weekly, and monthly checks helps operators sustain uptime while enabling predictive maintenance based on machine telemetry. Below is a checklist that outlines recommended preventative maintenance actions and priorities for shop-floor teams.

The checklist below highlights recurring maintenance tasks that support continuous operation.

Preventative steps that most significantly extend lifespan include regular anilox cleaning to preserve ink transfer, scheduled lubrication of bearings and gearless motor supports, and routine calibration of registration systems to prevent cumulative misalignment. Consistent cleaning prevents scoring and contamination that lead to poor print density, while lubrication and alignment checks minimize mechanical stress on precision components. Software and firmware updates also play a role in maintaining compatibility with automation modules that manage torque, tension, and registration. Implementing these tasks in a documented maintenance plan reduces emergency repairs and helps predict spare part needs, which connects to the importance of stocking critical components.

Maintaining an inventory of key spare parts—such as anilox cores, bearings, drive belts, and common sensor modules—combined with access to authorized technical service significantly shortens mean time to repair and supports contractual uptime guarantees. Using OEM parts ensures fit and performance, while service contracts with response-time commitments reduce the operational risk associated with long lead times for repairs. Establishing recommended stock levels for wear parts based on run rates and lead times, and scheduling periodic preventive service visits, preserves throughput and protects investment. Operators that pair documented spares strategies with manufacturer-backed support tend to achieve higher overall equipment effectiveness, which naturally leads into how these machines are applied across industry segments.

Advanced flexo printing machines find application across food and beverage, pharmaceutical, industrial, and retail packaging where requirements vary from high-speed commodity runs to highly regulated, traceable, and tamper-evident solutions. Each industry imposes unique demands: food packaging needs compliance with print hygiene and barrier compatibility, pharmaceuticals require traceability and documentation, and industrial markets prioritize durability and functional printing on technical films. Selecting the right machine class depends on production scale, substrate types, and quality expectations; procurement teams should align machine features—CI, gearless servo, automation, and ink systems—with the target product formats. The subsections below describe specific fit-for-purpose considerations for food/beverage and industrial/pharmaceutical segments and close with supplier offerings relevant to these applications.

Flexo printing suits food and beverage packaging because it supports high-speed runs on barrier films, is compatible with food-grade inks and lamination processes, and enables efficient multi-color branding with low per-unit costs at scale. Regulatory considerations include ink migration limits and hygienic handling during printing, which are addressed through proper ink selection, controlled curing/drying, and cleaning protocols. For snack pouches and flow-wraps, CI presses provide the edge-to-edge graphics and consistent color required for retail shelf impact, while automation reduces make-ready and contamination risks. These operational advantages make flexo a practical choice for packaging converters focused on cost, speed, and compliance.

Industrial and pharmaceutical packaging demands precise registration for variable data, consistent barrier layer printing, and documentation to support traceability and regulatory audits, and flexo machines deliver these capabilities when equipped with reliable registration, inline inspection, and data capture systems. Multi-layer lamination compatibility and the ability to print on high-barrier films are critical for protecting product integrity, and gearless servo control supports the tight tolerances required for serial numbers, batch codes, and tamper-evident features. Suppliers that offer customization, validated testing, and post-sales support help regulated manufacturers meet documentation and validation workflows, and those supplier services are often decisive during procurement.

Kingdom Machine Co., Ltd. / China Evergreen Machinery Co., Ltd. supplies a range of equipment relevant to these industry applications, including blown film extrusion lines, plastic bag making machines, and flexible printing machines capable of CI and gearless servo configurations. The company highlights manufacturing scale, sample delivery within days for standard machines, and bulk production lead times that support rapid deployment for converters seeking to scale. Their one-stop service and in-house R&D laboratory provide a practical path for customization and validation projects, and interested teams commonly request detailed model specifications and service terms to finalize procurement decisions.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;