Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Plastic pelletizing machines are industrial systems that convert shredded or flaked plastic waste into uniform pellets suitable for reuse in manufacturing, and they form a critical bridge between collection and reintegration of recycled resin into the supply chain. By melting, filtering, and cutting extruded plastic into consistent granules, pelletizing reduces material variability and enables higher-value reuse, lowering demand for virgin resin while improving process control. This guide explains how pelletizers work, compares the major pelletizing system types, maps materials and applications, outlines an end-to-end pelletizing process with quality checkpoints, and provides practical selection criteria to match equipment to recycling goals. Readers will learn the operational tradeoffs—throughput, pellet quality, cooling method—and the preprocessing needs of HDPE, LDPE, PP and PET streams. The article also highlights recent innovations and market drivers shaping adoption in 2024, with practical procurement guidance and selective supplier information for teams ready to source complete plastic recycling lines.

A plastic pelletizing machine is a piece of recycling equipment that converts molten plastic from an extruder into uniform pellets by cutting and cooling extrudate, enabling waste streams to become feedstock for new products. The mechanism typically couples an extruder and die head to a pelletizer cutter and cooling/separation system, producing pellets with controlled size and moisture suitable for downstream molding or extrusion. Pelletizing delivers three main operational benefits: stabilized melt flow for manufacturing, reduced contamination through filtration and degassing prior to cutting, and consistent pellet geometry that simplifies handling and packaging. These outcomes reduce material costs, divert waste from landfills, and support circular-economy targets by turning post-industrial and post-consumer scrap into valuable recycled resin. Understanding these fundamentals clarifies why pelletizing is often the central investment for recycling plants seeking scalable, quality-controlled reprocessing.

A pelletizing machine precisely cuts extruded plastic into small, typically spherical or cylindrical, pellets that meet dimensional and moisture specifications required by converters. The device sits after extrusion in a recycling line—following shredding, washing, drying and extrusion—and its role is to form stable, transportable pellets that mimic virgin resin handling properties. Typical outputs range from 2–4 mm pellets with controlled MFI implications, produced continuously to match extruder throughput and downstream storage. Equipment choice and die/cutter configuration determine pellet shape, surface finish, and initial moisture; these attributes influence reclaim grade and end-use suitability. Clear specification of expected pellet properties at procurement ensures the pelletizer integrates properly with upstream washing/drying and downstream sieving and packaging.

Pelletizing reduces dependency on virgin polymer by converting scrap into usable resin, cutting material costs and greenhouse-gas intensity per unit of production through avoided extraction and polymerization energy. Recent industry estimates indicate mechanical recycling via pelletizing can lower cradle-to-gate emissions compared with virgin resin by substantial margins, depending on feedstock and process energy mix. Economically, value recovery from otherwise landfilled scrap typically yields cost savings that offset equipment amortization when throughput and quality targets are met. Pelletizing also enables compliance with recycled-content mandates, improving market access for manufacturers seeking certified recycled inputs. Recognizing these environmental and financial benefits supports investment decisions and helps prioritize process controls that maximize yield and resin quality during reprocessing.

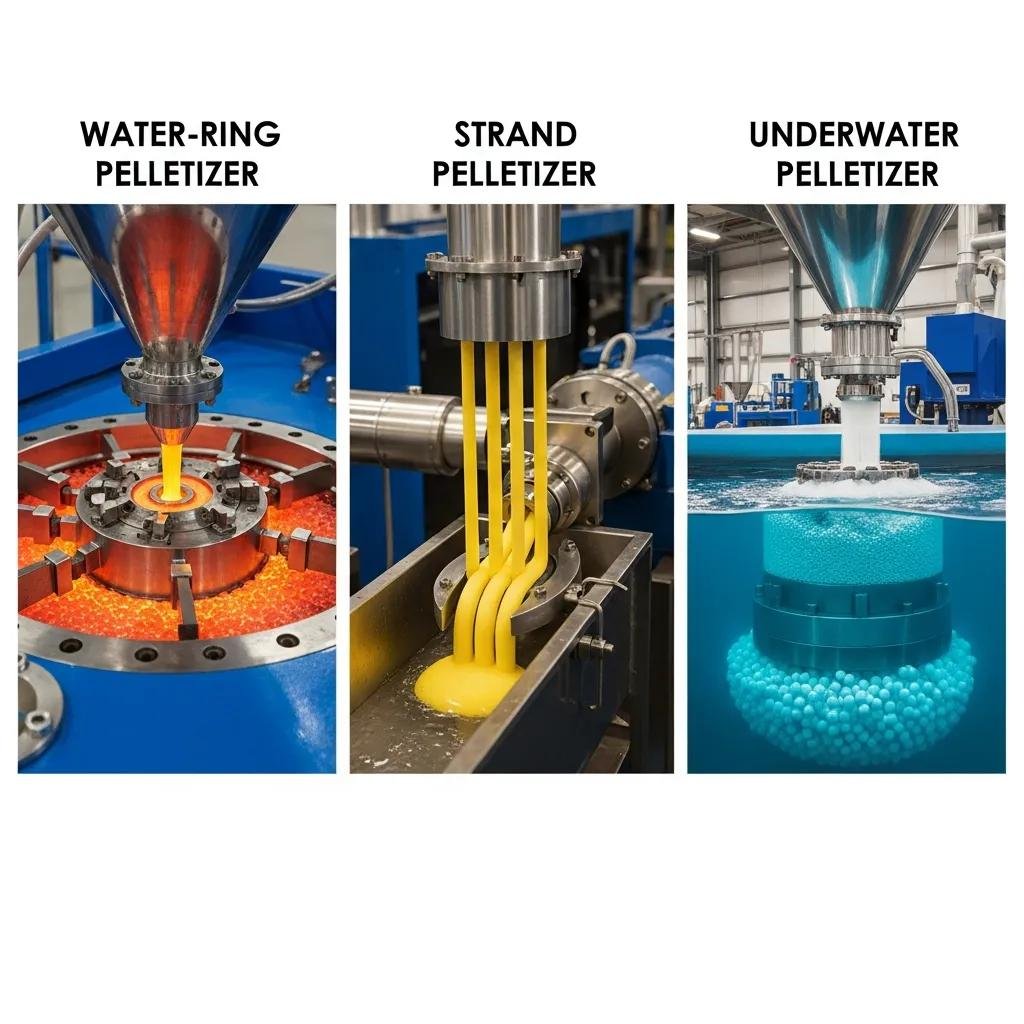

Different pelletizing systems use distinct cutting and cooling methods that make them better suited to certain plastics and contamination profiles; matching pelletizer type to feedstock is essential to achieve target pellet quality and throughput. The main types—water-ring (wet) pelletizers, strand pelletizers, and underwater pelletizers—differ by cooling medium, pellet shape, and upstream requirements, leading to tradeoffs in maintenance, pellet consistency, and capital layout. Choosing the proper pelletizer reduces downstream drying needs, minimizes fines and agglomeration, and improves throughput for specific materials. The following comparison clarifies suitable materials, throughput expectations, pellet quality, and cooling methods.

Introductory comparison of common pelletizer types:

| Pelletizer Type | Suitable Materials | Typical Throughput | Pellet Quality | Cooling Method |

|---|---|---|---|---|

| Water-ring (wet) | PE film, LDPE film, PP film | Medium–high (kg/hr scale) | Round, smooth pellets | Water-ring quench |

| Strand pelletizer | PET, rigid PP/PE, high-viscosity resins | Low–medium | Uniform cylindrical pellets | Air-cooled or water bath |

| Underwater pelletizer | PET bottle flake, engineering plastics | Medium–high | Dense, high-quality pellets | Water cutting & immediate quench |

Water-ring pelletizers cut molten extrudate against a rotating knife into droplets that are immediately entrained and shaped in a high-speed water ring, which quenches and conveys pellets to separation. This wet cutting yields near-spherical pellets well-suited for flexible-film streams where surface finish and roundness reduce bridging and improve downstream handling. Water-ring systems handle high throughput of low-viscosity resins like LDPE/LLDPE films but require robust water treatment and separation to manage fines and contaminants. Maintenance considerations include knife wear, ring clarity, and reliable pellet-water separation to minimize rejects. For film recyclers prioritizing throughput and pellet shape over minimal dryer footprint, water-ring pelletizing is frequently the preferred approach.

When to contact supplier: If your operation processes high volumes of PE/PP film and needs turnkey water-ring lines with integrated separation and washwater management, request equipment specifications and lead-time estimates from vendors.

Strand pelletizers extrude polymer strands that cool in air or water baths before being cut into pellets, producing cylindrical granules with consistent geometry; underwater pelletizers cut directly into a water stream for rapid quench and are preferred for hygroscopic or high-melt-index materials like PET. PET reprocessing typically requires stringent upstream washing and drying to control moisture and acetaldehyde levels; underwater pelletizers can yield dense, low-fines pellets that simplify downstream sieving. Operationally, strand systems are simpler and easier to maintain but take more floor space for strand cooling, while underwater units need precise water handling and separation equipment. When processing rigid containers or engineering plastics where moisture control and pellet density are critical, strand or underwater systems usually deliver the necessary pellet quality.

When to contact supplier: Reach out to suppliers when you need solutions for PET bottle flake or rigid plastic streams that prioritize pellet density, low fines, and integrated drying strategies.

Pelletizing is the central step in a multi-stage recycling flow that begins with collection and sorting and ends with sieved, dried pellets packaged for resale or internal use. The process addresses contamination, melt stability, and dimensional control through sequential mechanical and thermal treatments that convert heterogeneous waste into homogenous pellets. Critical control points—flake size, moisture content, melt filtration and degassing, cutter speed and die design, and cooling/separation efficiency—dictate final pellet properties and yield. Understanding the full sequence and its parameters helps operators optimize energy use, minimize rejects, and ensure consistent product that meets buyer specifications.

The pelletizing sequence includes collection, sorting, shredding, washing, drying, extrusion with filtration/degassing, pelletizing, cooling/separation, drying/sieving, and final QC—each step with measurable parameters to control quality. Typical targets include flake sizes below 20–30 mm for efficient extrusion, moisture below 0.1–0.5% for PET to avoid hydrolytic degradation, melt-filtration to remove particulates, and cutter/die settings that produce specified pellet diameters.

This stepwise flow clarifies where investment in equipment and controls yields the largest gains in pellet quality and process yield.

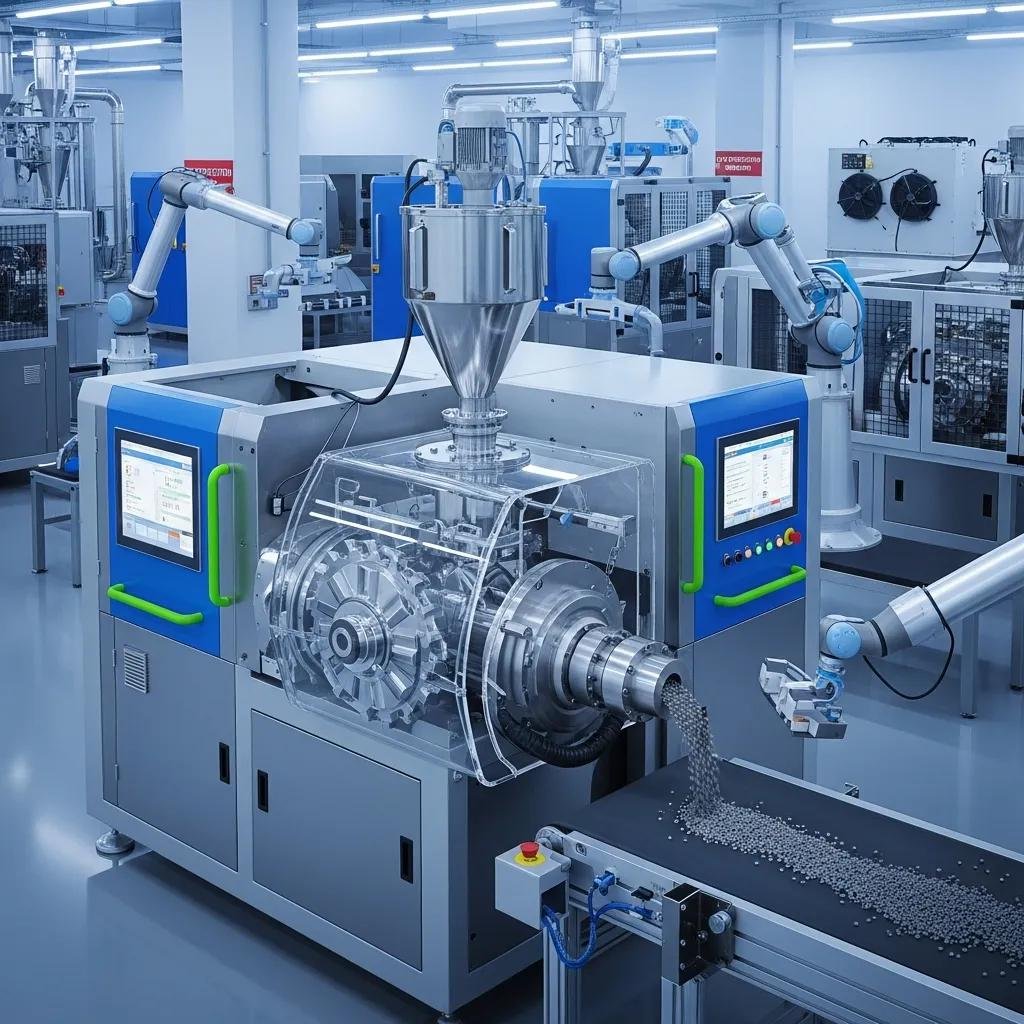

A pelletizing line comprises shredders/granulators, washing systems, dryers (centrifugal or thermal), extruders (single or twin-screw with L/D specifications), die heads, pelletizer cutters, cooling/separation units, and sieving/packaging systems. Key features to evaluate include extruder L/D ratio, screw configuration for melting and devolatilization, die size and cutter speed control for pellet consistency, and robustness of water treatment or air cooling subsystems. Maintenance and uptime considerations demand accessible knife assemblies, modular filtration elements, and clear instrumentation for temperature and pressure monitoring. Selecting components with compatibility across the line ensures stable production and simplifies troubleshooting when material variability emerges.

Pelletizing machines process a broad range of thermoplastics, with specific preprocessing, drying and pelletizer types suited to each material; matching equipment to material minimizes degradation and preserves desirable polymer properties. Common target materials include HDPE, LDPE/LLDPE, PP, and PET, each with distinct contamination sensitivities and melt behaviors that affect upstream washing, drying, and melt-filtration requirements. Understanding these differences informs decisions about whether to use wet or dry pelletizing methods, required filtration fineness, and acceptable MFI ranges for intended applications.

Introductory compatibility overview and EAV table purpose: the table below maps common materials to preprocessing needs, ideal pelletizers, and expected pellet properties to guide equipment selection.

| Material | Preprocessing Needs | Ideal Pelletizer Type | Expected Pellet Properties |

|---|---|---|---|

| HDPE | Washing; remove labels/inks | Strand or underwater | Dense, good mechanical properties |

| LDPE / LLDPE film | Thorough washing; float-sink separation | Water-ring pelletizer | Round pellets, moderate bulk density |

| PP (rigid & film) | Washing; remove fillers | Water-ring (film) / strand (rigid) | Consistent MFI, good flowability |

| PET bottles | Intensive washing, drying to <0.1% moisture | Underwater pelletizer | High-density, low-fines pellets |

Each material demands tailored handling: LDPE/LLDPE films benefit from water-ring pelletizing after float-sink separation to remove contaminants, while HDPE rigid parts typically require strand or underwater pelletizing for denser pellets. PET bottle reprocessing is most sensitive to moisture and requires robust drying and degassing before pelletizing to avoid molecular weight loss. Melt-flow index (MFI) expectations and color/contaminant limits should be defined prior to equipment selection, as they determine the degree of filtration and potential need for additive dosing or compatibilizers. Proper match of pelletizer type to material preserves mechanical properties and opens more valuable end-market opportunities.

Post-industrial feedstock is often cleaner and more homogeneous, enabling simpler washing and lower-cost pelletizing solutions, whereas post-consumer streams demand thorough sorting, more intensive washing, and higher-spec filtration and pelletizing systems to control contaminants. Economics differ: post-industrial operations can run at higher yield and lower per-kg preprocessing cost, while post-consumer recycling may require additional investments in sorting and quality assurance to achieve marketable pellet specifications. Operators should evaluate feedstock variability, contamination rates, and target product grades when sizing pelletizing equipment and estimating OPEX versus expected revenue from recycled pellets.

Selecting the correct pelletizing machine requires matching material type, target throughput, energy efficiency, maintenance capacity, and desired pellet quality to available technologies and supplier capabilities. A structured decision approach—assessing capacity needs, specific energy consumption, maintenance intervals, spare-parts access, and customization options—reduces procurement risk and enables predictable ROI. Buyers should also consider vendor service levels, testing support, and delivery timelines to ensure equipment meets production ramp targets.

Intro paragraph to decision matrix and checklist: the decision matrix below compares machine model types against selection criteria to guide procurement choices.

| Machine Type | Capacity | Energy Use | Maintenance | Recommended Use-case |

|---|---|---|---|---|

| Water-ring pelletizer | High | Moderate | Moderate (water handling) | High-volume film recycling |

| Strand pelletizer | Low–Medium | Low | Low–Medium | Rigid plastics, simple setups |

| Underwater pelletizer | Medium–High | Higher | Higher (water & separation) | PET bottle flakes, dense pellets |

Key spec-match metrics include target kg/hr throughput, specific energy consumption (kWh per kg), extruder motor sizing relative to throughput, and melt-filtration fineness. Capacity planning often uses simple scaling: required throughput (kg/hr) divided by expected yield from preprocessing determines extruder sizing and pelletizer capacity. Benchmark KPIs include kg/hr per motor kW and specific energy targets that vary by material; these help compare vendors on operational cost. Maintenance planning should account for knife life, filter element swaps, and potential water-treatment maintenance for wet systems. Considering these factors in procurement ensures the selected machine delivers on quality and total cost of operation.

Checklist for selecting a pelletizing solution:

Typical customizations include tailored die designs, cutter configurations, integrated filtration and degassing modules, automation packages, and bespoke packaging/labeling for finished pellets. Suppliers often offer one-stop solutions that can include line layout, electrical controls, PLC integration, and testing protocols to validate pellet properties. Procurement timelines vary by customization level; ready configurations generally ship faster while bespoke designs require longer engineering lead time. Ask suppliers about spare parts kits, on-site commissioning, and training to ensure long-term uptime and predictable maintenance.

Business integration note: Suppliers such as Kingdom Machine Co., Ltd. and related manufacturing partners offer full plastic recycling machine solutions with dedicated R&D and engineering, customization options including logo and packaging changes, and quality controls like 100 percent final inspection during production. Their operational assurances include competitive pricing driven by large-scale production, rapid sample delivery within 3 days, bulk lead times around 15–20 days, and product reliability measures including a two-year warranty on timer switches and a defect control range between 1%–3%. For buyers evaluating turnkey lines that require customization and testing support, request specification sheets and availability to confirm alignment with your processing targets.

Final procurement prompt and lead-capture CTA: If you require tailored pelletizing lines, specify material type, target throughput (kg/hr), and pellet specifications to receive an equipment recommendation and lead-time estimate.

Recent innovations focus on energy efficiency, improved cutter and die technology, automation and digital monitoring, and tighter integration with sorting and traceability systems to improve yield and pellet quality. Advances in extruder design and cutter metallurgy reduce fines and increase uptime, while process control systems and sensors enable real-time quality feedback and energy optimization. Regulatory drivers—extended producer responsibility (EPR) schemes and recycled content mandates—continue to increase demand for reliable pelletizing capacity. These trends position mechanical pelletizing as a scalable, cost-effective pathway to meet 2024 circular-economy commitments.

Major technical improvements include higher-efficiency extruder screws and drives, advanced cutter geometries that reduce shear and fines, optimized die-head designs for consistent pellet size, and AI-enabled process monitoring that correlates sensory data to pellet quality metrics. Integration with upstream AI sorting and near-line spectroscopy supports contaminant detection before extrusion, reducing rejects. Such innovations yield lower specific energy consumption, higher yield, and more uniform pellets that command higher value in recycled-content markets. Adopting these technologies requires evaluating total cost of ownership versus the incremental yield and quality improvements they deliver.

Market drivers include stronger recycled-content requirements, corporate sustainability commitments, and policies incentivizing mechanical recycling capacity. Recent market summaries indicate growing demand for pelletized recycled resin across packaging, non-food applications, and industrial uses. As regulations evolve, producers and recyclers invest in pelletizing capacity to secure feedstock and comply with product stewardship obligations. For buyers and planners, aligning equipment capability with regulatory trajectories and end-market specifications ensures long-term demand for recycled pellets and supports scalable circular-economy solutions.

This final guidance synthesizes selection, operation, and market context to help recycling teams make informed equipment and process choices.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;

pelletizer machine plastic