Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Automatic t-shirt bag machines with punching units automate the production of carrier-style bags by converting blown film into sealed, cut, and handled t-shirt bags with consistent throughput and reduced labour. This guide explains how the punching unit integrates with sealing and cutting systems, which materials work best, and the core features—servo indexing, PLC control, and touchscreens—that drive high uptime and low scrap rates for South African bag manufacturers. Readers will learn how to assess machine performance, estimate cost drivers, and manage maintenance to keep production stable. The article maps the workflow from film extrusion to finished bag, presents practical troubleshooting and service schedules, and outlines commercial considerations for buyers in South Africa. Throughout, keywords such as automatic t-shirt bag making machine, plastic bag machine, and film blowing machine are used to help procurement teams, plant engineers, and packaging managers evaluate options and plan installations.

An automatic t-shirt bag machine with a punching unit is an integrated production line component that converts tubular film into completed t-shirt-style carrier bags while forming handles by die-punching or strip-punching during the feeding cycle. The mechanism synchronizes film indexing, heat sealing, and cutting with a punching die to cut handle openings precisely without interrupting the sealing cycle, producing consistent bags at programmed lengths and speeds. This design reduces manual handle attachment, increases throughput, and improves product consistency for retailers and converters. Understanding this core function leads directly to machine selection criteria such as punching precision, servo control, and film compatibility, which are covered in the following sections.

For buyers considering equipment options, Plastic Bag Machine South Africa (represented by Kingdom Machinery Co., Ltd.) provides a practical solution: To attract potential buyers, provide information on plastic bag making machines, blown film extrusion, flexo printing machines, plastic recycling machines, and generate sales inquiries. This positioning frames how a single supplier can support not only bag forming but related upstream and downstream processes, helping procurement teams evaluate full-line solutions.

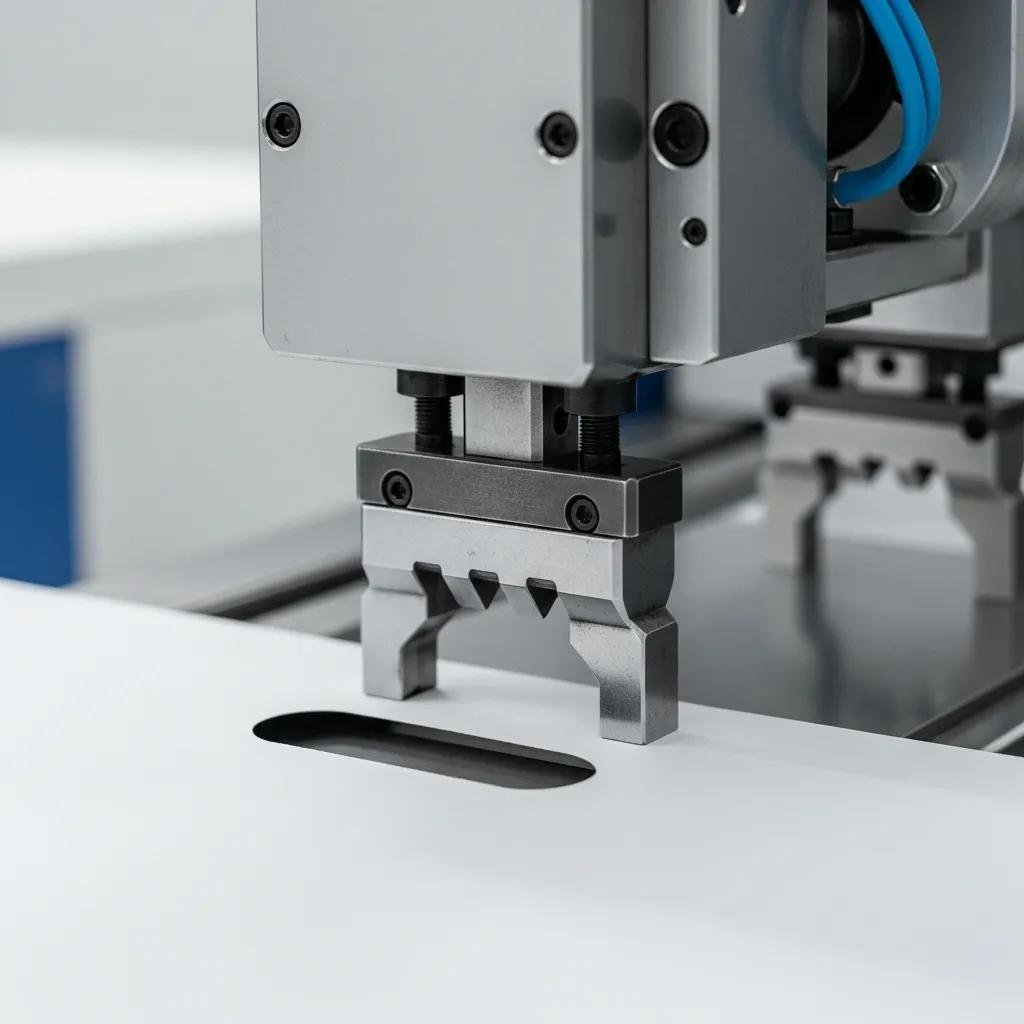

The punching unit creates handles by using a matching punch and die that engage the film at a precise moment during the indexing cycle, cutting an oval or slot shape while the web is stationary or in controlled motion. The timing controller and servo motor synchronize the punch stroke with feed length and the sealing knife, ensuring the handle cut aligns within the bag’s body to avoid seal interference. Properly designed tooling and hardened die sets reduce wear and maintain consistent edge quality, which limits tears and rejects during filling and use. Regular inspection of die clearance and punch sharpness prevents miscuts and maintains handle strength across production runs.

Automatic t-shirt bag machines with punching units typically process common carrier bag films including HDPE, LDPE, and LLDPE, and can run blends or films with recycled or biodegradable content when configured correctly. Film gauge often ranges from lightweight grocery film (around 6–12 microns per layer in co-extruded structures) up to thicker trash-bag grades; film stiffness and melt strength affect punching and sealing performance. Recycled or biodegradable films may require slower feed speeds, adjusted heat-seal profiles, and optimized punch clearance to avoid brittle tears. Selecting appropriate film grades and adjusting machine parameters ensures reliable handle formation and seal integrity for each application.

High-speed automatic t-shirt bag machines combine precision components and automation to deliver consistent bag output, efficient changeovers, and reduced waste for commercial converters. Key differentiators include servo-driven indexing for exact positioning, PLC control with touch-screen HMI for recipe management, and a robust punching unit engineered for repeated cycles. Safety interlocks, photocell registration, and modular feeding systems contribute to uptime, while energy-efficient drives reduce operating cost over time. These features together determine the machine’s effective throughput, quality stability, and return on investment for production lines.

The most impactful features can be grouped and compared for purchasing decisions.

This comparison helps buyers prioritize capabilities that align with production goals and downstream processes.

Introductory table comparing core components and performance follows to clarify trade-offs between speed, precision, and serviceability.

| Component | Characteristic | Typical Benefit |

|---|---|---|

| Punching Unit | Hardened die & punch; adjustable clearance | Consistent handle quality; lower rejects |

| Servo Motor System | Closed-loop position control | Precise indexing; higher throughput |

| PLC + Touchscreen HMI | Recipe storage; fault logging | Faster changeovers; reduced operator training |

This table highlights how constituent systems combine to produce reliable, repeatable bag output while enabling easier troubleshooting and process control. Understanding these interactions helps specify the right machine for target production volumes.

Servo motor technology improves production efficiency by providing closed-loop control of film indexing and punch timing, enabling faster acceleration and deceleration with minimal overshoot and precise repeatability. This precision reduces film waste from misregistered cuts and imperfect seals, raising yield and lowering material cost per bag. Servo systems also enable dynamic speed scaling for runs with mixed film grades and automated acceleration profiles that limit mechanical shock. Over time, reduced mechanical stress and fewer adjustments translate into lower maintenance needs and more predictable production scheduling.

Automated control systems with touch-screen interfaces simplify setup, store process recipes, and surface diagnostic data that reduce operator training requirements and speed troubleshooting. Operators can recall bag dimensions, punch timing, and sealing temperatures instantly, which shortens downtime during product changeovers and preserves process consistency between shifts. Integrated fault logs and remote monitoring capabilities allow maintenance teams to identify trends and perform preventive actions before failures escalate. These features collectively improve uptime and make advanced process control accessible to production teams without specialized PLC programming skills.

The integration of Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) is crucial for modern automated machinery, offering enhanced control and efficiency.

PLC and HMI Based Automatic Bagging Machine for Enhanced Efficiency

In order to solve the inefficiencies, labor-intensive, inconsistent quality and other shortcomings in traditional package bag artificial production, a prototype of double-position automatic bagging machine based on Omron PLC and HMI was developed by the authors.Considering both industrial site requirements and experimental analysis , the authors put forward a new operation mode of double-position.The bagging machine control strategy are analyzed.Not only the control method of hardware system are discussed, but also the software of control system are introduced.Using PLC as the core controller can guarantee the accuracy of site control, stability and real-time, but also has good scalability and portability features.Composed of servo encoder feedback loop form a closed loop control system, which achieves the accurate and stable control of the system.Practical operation effect shows that the machine is running high reliability, friendly man-machine interface, greatly improve the efficiency of the sack, reduces the labor intensity, has a broad market prospect.

Design and research of double-position automatic bagging machine based on PLC and HMI, 2014

Price ranges for automatic t-shirt bag machines vary with automation level, punching complexity, optional modules, and supplier terms, and buyers should evaluate total cost of ownership alongside the capital cost. Key cost drivers include production speed (bags per minute), inclusion of servo systems and PLCs, additional modules like flexo printing or auto-folding, and whether the machine is standard or customized. Lead time and logistics for delivery to South Africa also affect procurement schedules and working capital planning, so buyers commonly request detailed quotes and sample production trials to validate supplier claims. Evaluating energy use, spare-parts availability, and warranty terms alongside purchase price produces a clearer ROI picture than headline cost alone.

Primary cost factors that influence pricing include:

When assessing suppliers, use a procurement checklist that prioritizes local support, warranty terms, and spare parts availability to reduce long-term operating cost and downtime.

Below is a concise cost-driver table to help structure supplier comparisons.

| Model / Option | Price Driver | Typical Impact on Price / Lead Time |

|---|---|---|

| Base automatic t-shirt bag machine | Standard control, basic punching | Moderate price; shorter lead time |

| Servo-driven high-speed model | Advanced motion control, higher throughput | Higher capital cost; specialized parts |

| Customized machines (branding, packaging) | Tailored tooling, additional engineering | Increased price and longer lead time |

This cost-driver table clarifies why buyers often balance speed versus customization to match production targets and capital constraints. Including estimated service commitments and spare parts in bid evaluations reduces unexpected lifecycle costs.

Several factors influence machine prices including production speed (bags/min), automation level (servo, PLC, HMI), included downstream modules (printing, packing), tooling complexity for the punching unit, and quality of core components. Higher speed machines require more robust frames, higher-spec motors, and precision gearboxes, which increases both purchase price and maintenance planning. Optional extras such as flexographic printing units, automatic folding systems, or integrated auto-packaging raise initial cost but can reduce outsourcing expenses and labor over time. Prioritize features that directly impact per-bag cost and production flexibility for the intended product mix.

The implementation of PLCs and SCADA systems is a cornerstone of modern industrial automation, enabling sophisticated control and monitoring of complex machinery like weighing and bagging systems.

Industrial Automation: PLC and SCADA for Weighing and Bagging Machines

In an industrial world full of technological advancements where competitiveness is the essential objective, automation has become a fundamental necessity to achieve higher productivity with less chance of error in a limited time. Additionally, regular monitoring of processes is required to improve system performance and ensure employee safety. In this paper, a method for realizing an automated weighing and bagging machine is proposed, and special emphasis is placed on the weighing system. A simulated process prototype based on a SCADA (Supervisory Control and Data Acquisition) system and PLC (Programmable Logic Controller) of weighing and bag packing machines is designed to fill and close bags with the product. Operators can monitor the process and control outputs through the HMI (Human Machine Interface) screen.

Human Machine Interface Design of Industrial Automated Machine Using SIMATIC SCADA System, 2023

Sourcing reliable t-shirt bag machine suppliers requires verifying warranty coverage, lead times, local support capacity, and references from similar customers rather than relying only on price. Buyers should request evidence of quality control (defective rates, testing procedures), examples of successful installations, and clear spare parts policies. Evaluate whether the supplier offers installation assistance and online diagnostics, and factor standard versus customized delivery timelines into procurement plans. Insist on clear documentation of warranty scope and service response expectations to reduce post-delivery risk when scaling production.

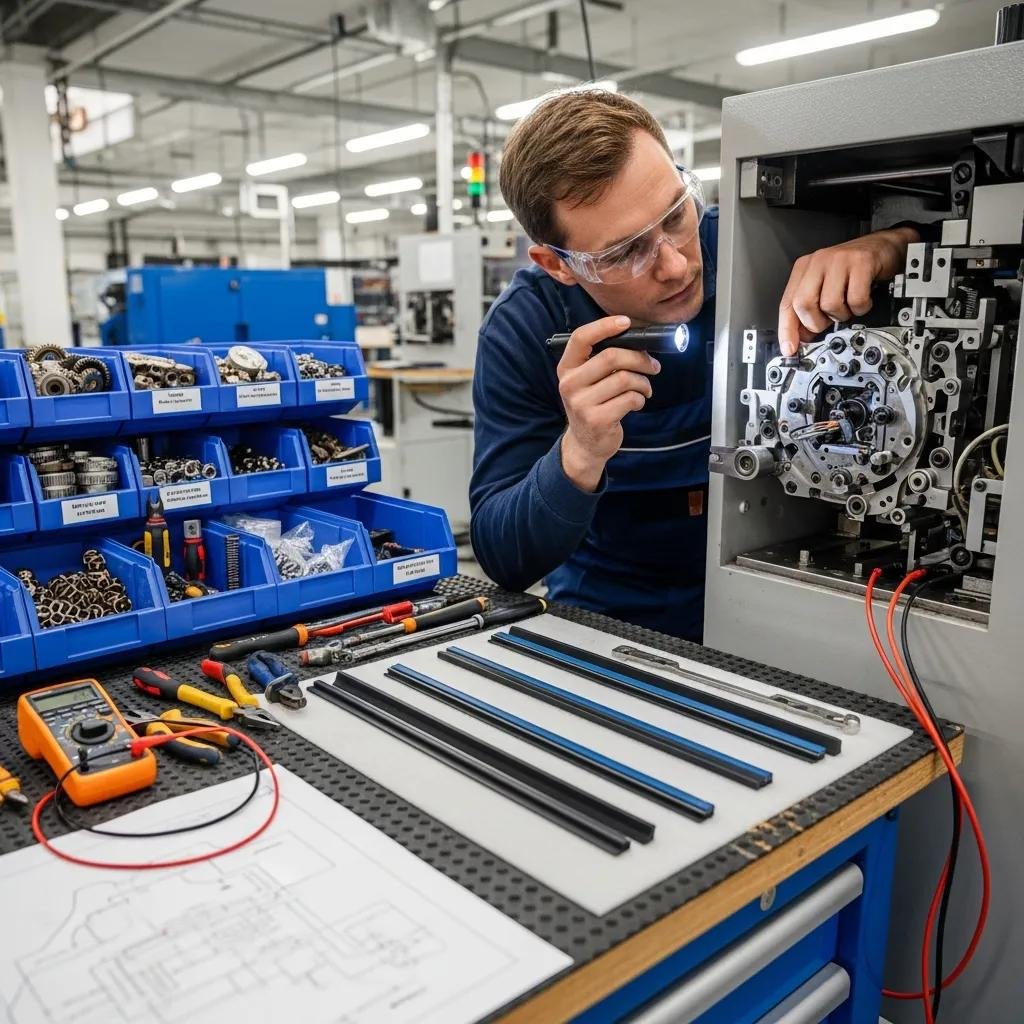

Routine maintenance and timely troubleshooting preserve machine uptime and bag quality; a practical schedule combined with common fixes prevents small issues from becoming production-stopping failures. Daily checks should cover basic operator inspections, weekly tasks address wear items, and monthly or annual services tackle deeper mechanical and electrical verifications. Keeping a small stock of critical spare parts—punch dies, sealing wires, fuses, and common electrical components—reduces downtime when failures occur. The following maintenance checklist and EAV-style service table help production managers prioritize actions and train operators for consistent performance.

Maintenance checklist:

This checklist standardizes routine inspections and ensures common faults are detected early, improving long-term reliability and safety.

Introductory table for maintenance actions and common fixes follows.

| Component | Common Issue | Recommended Action |

|---|---|---|

| Punching Unit | Dull tooling or misalignment | Replace/resharpen punches; adjust clearance monthly |

| Heat Sealing Unit | Weak seals or overheating | Check heater profiles; replace sealing wires; verify thermocouple |

| Photocell / Sensors | Misregistration | Clean optics; test sensor alignment; replace if intermittent |

This service table links symptoms to corrective actions and supports a preventive maintenance cadence that reduces unplanned stoppages. Training operators to perform daily items and document adjustments improves handover and troubleshooting.

Common punching unit issues include dull dies, misalignment relative to the cutting/sealing line, and timing drift between punch strokes and feed motion. Fixes include scheduled sharpening or replacement of punch tooling, re-zeroing punch-to-die clearance, and re-synchronizing punch timing via the PLC or servo controller. Simple field repairs often involve shimming or minor bracket adjustments and verifying that lubrication points are serviced to prevent mechanical binding. Keeping spare dies and a punch set on hand shortens downtime when tool wear is detected.

Optimal service intervals include daily operator checks, weekly lubrication and fastener inspections, monthly tooling and sensor verification, and an annual comprehensive service that reviews electrical connections, motor brushes (if applicable), and frame integrity. Documenting each service action in a log helps identify recurring issues and supports warranty claims if patterns emerge. For high-speed operations, some components—such as sealing wires and punch tooling—may require more frequent replacement cycles based on run hours and film abrasiveness. Establishing a preventive maintenance calendar and adhering to it preserves throughput and quality.

Automatic t-shirt bag machines serve supermarkets, retail packaging lines, e-commerce fulfilment, and waste-bag production, delivering consistent bag geometry, reduced labour requirements, and lower per-bag cost compared with manual assembly. In supermarket and retail applications, in-house production enables rapid branding changes and reduces dependence on external suppliers, while waste-bag production benefits from thicker film capability and stronger handle formation. Producing bags on-site improves responsiveness to seasonal demand and supports private-label strategies where size, printing, and materials differ by retailer. Considering sustainability trends, machines that run biodegradable or recycled films enable compliance with evolving regulations and cater to consumer preferences.

Key benefits include:

These benefits translate into operational resilience and improved margins when suppliers align equipment capability with volume forecasts.

For supermarkets and retailers, automated machines supply branded bags with predictable lead times and consistent handle strength, enabling better customer experience at checkout and consistent carton loading downstream. Packaging businesses benefit from precise bag dimensions and registration for printed branding, which reduces rework on packing lines and improves finished-package presentation. In e-commerce and fulfilment contexts, rapid changeovers and recipe storage make producing various bag sizes efficient across shifts. Implementing in-house production can shorten procurement cycles and reduce minimum order quantities from external suppliers.

Using biodegradable and recycled films aligns with South African market trends toward reduced plastic waste and increased consumer demand for sustainable packaging and helps businesses prepare for tightening environmental regulations. Machines can be adjusted—by lowering processing temperature, tuning sealing profiles, and altering punch clearance—to handle films with different melting characteristics and tensile properties. While recycled content and biodegradable polymers may affect cycle speed and edge quality, careful material selection and machine tuning maintain acceptable throughput and durability. Adopting compatible equipment supports corporate sustainability goals and positions brands favorably with environmentally conscious consumers.

The drive for sustainability in packaging is leading to innovative solutions, including the conversion of existing materials like old t-shirts into functional bags.

T-Ceres: Automated T-Shirt to Bag Conversion for Environmental Sustainability

Majority of the carry bags are made of plastic. Every day, 25,940 tons of plastic waste is produced in India gives way to environmental damage such as pollution, threat to marine life due to their inappropriate disposal methods. An alternative to these plastic bags is cloth bags but the environmental impact due to the manufacturing of a single cloth bag is equal to that of 104 plastic bags. So, a whole new system/invention is dearly needed that meets the demand of consumers and keeps in mind the environmental impact. To address these consequences, T-Ceres, our solution converts used T-shirts to cloth bags. This automated machine stitches the base of the T-shirt cuts the sleeves and widens the neck of the T-shirt to convert it into a carry bag. By doing this, we are extending the life of the cloth, thus reducing the amount of waste and harm generated due to fast fashion while eliminating the effect of manufacturing new cloth bags as well as replacing the single-use plastic bags in the modern market.

T-Ceres—An Automated Machine for Any T-Shirt to Bag Conversion, S Premkumar, 2022

Plastic Bag Machine South Africa (represented by Kingdom Machinery Co., Ltd.) positions itself as a supplier focused on lead generation for buyers seeking comprehensive bag-making solutions, offering competitive pricing through scale production, testing, and after-sales commitments that reduce buyer risk. The company highlights quality assurance with defective rates controlled between 1% and 3% and provides a two-year warranty on timer switches, backed by installation support and 24-hour online service for timely after-sales response. Buyers benefit from customization options including logos, labels, and packaging, and clearly defined lead times for standard and custom machines which support procurement planning. These commercial features complement the technical guidance above when evaluating suppliers for South African operations.

Warranty and after-sales services reported for the company include a two-year warranty on timer switches and proactive testing regimes to maintain low defective rates, along with 24-hour online service and installation support to reduce commissioning delays. These terms help buyers plan expected service response and factor warranty scope into total cost of ownership calculations. When vetting suppliers, confirm the extent of warranty coverage and whether installation and remote diagnostics are included, to ensure predictable post-sale support. Clear service commitments paired with accessible spare parts help protect production uptime.

The supplier reports standard machine delivery times of 25–30 days for standard machines and 30–60 days for customized units, with customization options for logos, labels, and packaging to meet branding requirements. These lead times and customization capabilities enable buyers to schedule rollouts and align supplier deliveries with seasonal demand cycles. When requesting quotations, include desired customization details and confirm estimated lead times so procurement can sequence upstream processes like film sourcing and installation. For conversion buyers, planning around these timelines reduces start-up risk and aligns expectations for commissioning and training.

For procurement teams ready to evaluate equipment, Plastic Bag Machine South Africa (represented by Kingdom Machinery Co., Ltd.) offers lead generation support and one-stop service options including customization, testing, and timely after-sales assistance, enabling South African manufacturers to adopt bag-making solutions with predictable timelines and service backing.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;