Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

LDPE blown film machines are specialized blown film extrusion systems designed to convert low-density polyethylene (LDPE) resins into tubular film by extrusion, bubble formation, cooling, and winding. These machines use a precise balance of screw design, die geometry, and air-ring cooling to control film gauge, clarity, and mechanical properties, producing films used across packaging, agricultural, and industrial markets. This guide explains how LDPE blown film extrusion works, the machine types available, key components that determine quality, practical selection criteria for manufacturers, operation and maintenance best practices, and how sustainability is integrated into modern production. Readers will find step-by-step process descriptions, component-level specifications, comparative tables for monolayer versus multi-layer and ABA lines, operational checklists, and manufacturer evaluation criteria to support purchasing decisions. By the end you will understand how material properties, machine configuration, and production parameters combine to deliver consistent LDPE film and how to assess suppliers and equipment to meet your production goals.

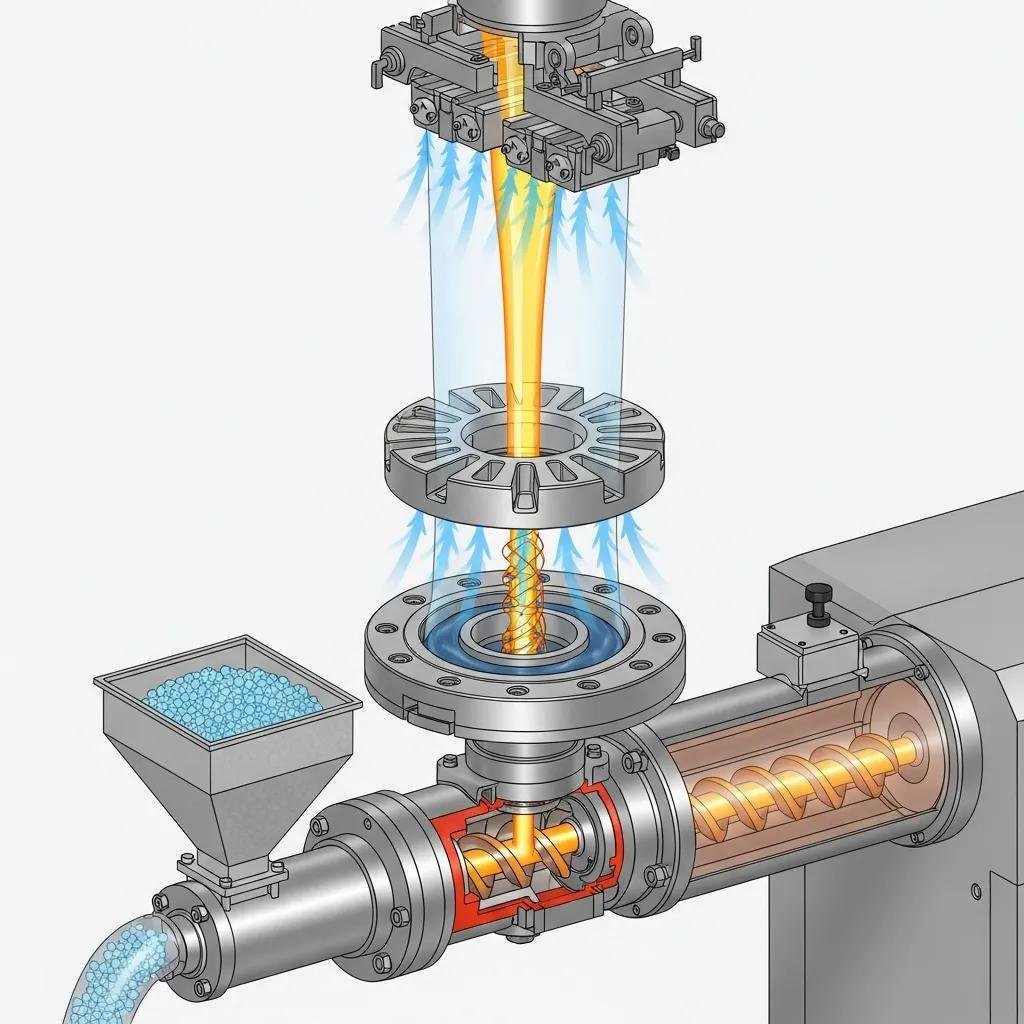

An LDPE blown film machine is a polymer processing line that melts LDPE pellets in a screw extruder, forces the melt through an annular die to form a tubular film, inflates the melt into a bubble with controlled air, cools the bubble to set film properties, and winds the flattened film onto rolls. This process converts LDPE’s low density and high chain branching into flexible, clear, and stretchable film through controlled cooling and draw-down; the mechanism relies on melt strength, die geometry, and air-ring efficiency to stabilize the bubble and control gauge. Understanding this flow helps operators select screw L/D ratios, die lip settings, and cooling profiles that match LDPE melt flow index and desired film attributes. Below is a concise three-step process summary to clarify the core stages for quick reference.

This three-step view provides the operational skeleton; the next section details LDPE properties that dictate precise machine settings and performance trade-offs.

Low-Density Polyethylene (LDPE) is characterized by a density typically around 0.910–0.940 g/cm³ and a melt flow index (MFI) range suitable for blown film processes, producing films with high clarity, elongation, and puncture resistance. LDPE’s branched molecular structure gives it good melt strength and extensibility, enabling stable bubble formation, though formulation and MFI selection influence output rate, processing temperatures, and draw-down ratios. For film producers, LDPE typically yields softer, more flexible films than HDPE and offers better sealing and transparency than many LLDPE blends; operators adjust screw speed, temperature profiles, and die gap to tune gauge and optical properties. These material-driven parameter choices lead directly into machine component considerations — specifically how extruder design, die head geometry, and air-ring cooling impact final film performance.

The extruder, die head, and air ring are meronomic elements of any blown film line; each component’s critical specs directly affect throughput, film uniformity, and clarity. Screw design (diameter, L/D ratio, compression ratio) controls melt homogeneity and output capacity, while die lip gap and die concentricity determine thickness control and edge quality; small deviations produce gauge bands or edge bead. The air ring controls cooling intensity and bubble stability—its design affects frost line position and surface finish—while haul-off and winder settings impact orientation and winding tension. Understanding these component interactions allows producers to select equipment tailored to LDPE’s melt behavior and the target film properties, enabling consistent production and simplified troubleshooting.

| Component | Critical Specs | Impact on Film Quality/Production |

|---|---|---|

| Extruder (screw & barrel) | Screw diameter, L/D ratio, compression ratio | Determines melt homogeneity, output capacity, and thermal history; affects clarity and neck-in |

| Die head (annular) | Lip gap control, concentricity, die land length | Controls film thickness accuracy, edge quality, and melt distribution |

| Air ring / cooling | Air flow uniformity, adjustable cooling zones, IBC capability | Stabilizes bubble, sets frost line, influences surface finish and gauge uniformity |

The table above clarifies how component specifications translate to measurable production outcomes and provides a basis for component-level inspection during procurement and commissioning.

After reviewing components, producers need guidance on machine configurations — monolayer, ABA, and multi-layer — and how those configurations map to products and scales of operation.

Choosing the right machine configuration depends on your end product, required barrier or mechanical properties, production scale, and budget. Monolayer lines are simplest and cost-effective for basic packaging films, while ABA or multi-layer systems provide tailored properties (barrier, strength, sealability) through layer-by-layer material selection. Multi-layer lines allow reclaimed-content layers without sacrificing surface performance, and ABA designs enable a central core of recycled or blended material with virgin LDPE on outer layers for clarity and heat-seal. Below is a comparison table to help match machine types to typical output and use cases.

| Machine Type | Output Capacity (typical) | Typical Film Types | Pros / Cons |

|---|---|---|---|

| Monolayer LDPE | Low–medium (economical lines) | Shopping bags, liners, simple packaging | Simpler, lower capex; limited barrier and mechanical tuning |

| ABA (A-B-A) | Medium | Clear packaging with recycled core or seal layers | Balance of performance and recycled content handling; moderate complexity |

| 3-layer / Multi-layer | Medium–high | Barrier films, shrink film, high-performance packaging | Best property control; higher capex and maintenance complexity |

This comparison clarifies trade-offs between cost, complexity, and final film capabilities; choose monolayer for basic flexibility and multi-layer or ABA when functional layers or recycled content are required. When you need configurable options or custom production profiles, many suppliers offer modular extruder stacks and tailored die heads to match capacity and material blends, and you can request quotes for specific line builds.

Monolayer LDPE blown film machines are compact, easier to operate, and well suited for producers focused on simple packaging products such as grocery bags, produce film, and light-duty liners. Typical monolayer lines deliver stable clarity and stretch with lower capital investment and simpler maintenance routines, making them attractive for converters with limited product complexity. Output ranges vary by extruder size and screw configuration, but monolayer systems emphasize simplicity: single-screw extruders, a single die head, basic air-ring cooling, and straightforward winding systems. These lines are best when barrier properties are not required and when throughput demands align with a lower-cost footprint, but upgrading to multi-layer becomes worthwhile if recycled content or advanced barrier properties are later required.

Multi-layer and ABA systems enable tailored film stacks where each layer contributes specific functions—outer layers for sealability and printability, inner core layers for stiffness or recycled content, and barrier layers for gas/moisture control. These configurations support demanding applications such as shrink film, co-extruded barrier packaging, and films that incorporate high percentages of recycled LDPE while preserving surface quality. Layer distribution and material selection also influence processability; for example, a high-MFI tie or adhesive layer may be required to bond dissimilar polymers in a multi-layer stack. While capex and maintenance complexity increase, multi-layer lines provide the performance needed for higher-value applications and allow producers to meet evolving sustainability targets through engineered layer placement.

| Machine Type | Attribute | Value |

|---|---|---|

| Monolayer LDPE | Typical industries | Retail bags, basic packaging, liners |

| ABA LDPE | Typical advantages | Recycled core with virgin surfacing; balanced cost/performance |

| Multi-layer LDPE | Typical use-cases | Barrier packaging, shrink film, high-performance wraps |

This structured comparison helps buyers weigh attributes against production targets and budget constraints; next we examine real-world applications of LDPE film to guide machine selection further.

LDPE films produced by blown film extrusion serve a wide spectrum of applications where flexibility, clarity, and sealability are important. Common application clusters include consumer packaging (bags, pouches, liners), agricultural films (mulch, greenhouse covers), and industrial products (tubing, protective layers). Matching the application to machine configuration and film specification optimizes production economics and ensures performance in service conditions. The following list highlights major application areas and what they typically require from film properties and machine features.

These application categories inform specific machine choices — for example, packaging converters often prioritize clarity and high-speed winder options, while agricultural film producers emphasize UV stabilization handling and thicker gauge capacity. The next subsections break down packaging and agricultural/industrial uses with recommended machine features.

Packaging applications demand films with controlled gauge, good optical properties, and sealability to protect goods and present products attractively. For retail bags and food packaging, thin gauges (measured in microns or g/m²) require precise die lip control and stable air-ring cooling to achieve uniform clarity and consistent seals; features like internal bubble cooling (IBC) and narrow gauge control systems help meet these needs. For printed flexible packaging, surface finish and corona treatment options influence downstream printing and lamination, which in turn guide the choice of die face and winding systems. Machine selection for packaging often prioritizes stable gauge control, effective chill/cooling systems, and reliable winder tension management to ensure consistent print and converting performance.

Agricultural films such as mulch and greenhouse covers require thicker gauges, enhanced UV resistance, and sometimes anti-condensation properties, which means the machine must handle higher output rates and incorporate capabilities for additive dosing and masterbatch feeding. Industrial applications such as tubing and liners need strong puncture and tear resistance, which benefits from tailored screw profiles, proper melt temperature control, and optional multi-layer constructions to embed strength layers. When producing durable agricultural or industrial films, operators should specify extruders with appropriate torque reserves and robust winding systems, and consider material-handling equipment for masterbatch and additive dosing to maintain consistent product performance.

Selecting a manufacturer requires evaluating quality assurance practices, warranty terms, after-sales support, customization capacity, and total cost of ownership rather than capital cost alone. Key validation steps include verifying testing and inspection protocols, understanding warranty coverage for critical components, confirming spare-parts availability and response times, and assessing a supplier’s ability to deliver customized solutions and production capacity. Below is a checklist-style list of questions and criteria to use when screening suppliers.

This checklist helps buyers focus conversations with vendors on operational reliability and long-term support rather than price alone; the next paragraphs detail specific QA and warranty items to confirm.

Quality assurance indicators include standardized testing protocols, documented final inspections, and machine commissioning support to verify performance against specifications; these measures reduce startup risk and ensure consistent output. Warranty considerations should cover critical electrical and mechanical components, with clarity on exclusions and spare-parts supply; rapid access to replacement parts and technical field service are essential for minimizing downtime. After-sales support also includes operator training, remote diagnostics capability, and documented maintenance schedules—elements that preserve machine uptime and extend useful life. When talking to suppliers, request copies of inspection checklists, typical warranty terms, and references for service response performance to validate claims.

| Manufacturer Attribute | Expectation | Why It Matters |

|---|---|---|

| Final inspection | 100% final inspection with test reports | Ensures delivered equipment meets specs and reduces commissioning issues |

| Warranty | Clear warranty on key components and replacement policies | Protects investment and reduces unexpected repair costs |

| After-sales support | Training, spare parts pipeline, and responsive service | Minimizes downtime and preserves production continuity |

Using this EAV-style comparison helps standardize supplier evaluation and prioritize those providing measurable QA and support commitments. The next subsection covers customization, production capacity, and pricing considerations in practical terms.

Customization allows tailoring screw geometry, die heads, and control systems to specific LDPE grades and product applications; it becomes cost-effective when the customization improves yield, reduces scrap, or enables higher-value products. Production capacity assessment should match projected demand with installed output, considering factors like shift cycles, expected OEE (overall equipment effectiveness), and spare parts lead times. Competitive pricing should be evaluated as part of total cost of ownership—energy consumption, maintenance intervals, and expected lifetime must be accounted for alongside upfront capex. When comparing vendors, ask for energy consumption metrics, typical lead times, and examples of customized solutions to understand how cost and performance balance for your specific production scenario.

Optimized operation and maintenance preserve film quality, maximize uptime, and reduce lifecycle costs. Best practices include standardized start-up and shut-down procedures, documented temperature and speed profiles for each material grade, pre-run checks for die concentricity and air-ring alignment, and scheduled preventative maintenance on drive systems and gearboxes. Implementing SOPs for material handling, moisture control, and masterbatch dosing reduces in-process variation and film defects. Below is a practical list of preventive maintenance and operational steps to incorporate into day-to-day production routines.

These routines reduce common failure modes and set the stage for targeted troubleshooting; the following H3s provide detailed operational tips and fault-resolution steps.

Consistent film quality depends on precise control of processing parameters: maintain stable barrel and die temperatures tailored to LDPE melt flow, optimize screw speed to balance output and shear heating, and adjust air-ring flow to stabilize the frost line. Material conditioning—drying or moisture control when necessary—and consistent masterbatch feeding prevent gels and streaks; monitoring melt pressure and die temperature trends supports incremental optimization. Use control panel/PLC recipes for repeatable setups across shifts and document parameter changes for continuous improvement. These operational controls lead directly into a set of troubleshooting routines for common defects.

Common issues include gauge variation, gels, frost line instability, and poor sealing; addressing them requires problem→cause→solution analysis. For gauge variation, check die lip concentricity, haul-off speed, and bubble cooling uniformity; for gels, inspect resin cleanliness and screen packs; for frost line instability, verify air-ring performance and melt temperature stability. Maintain a spare-parts list for screen packs, die lips, heaters, and timer switches to accelerate repairs; regular preventive checks on bearings, gearboxes, and winding systems reduce the likelihood of sudden failures. Applying these procedures systematically reduces scrap and keeps production within target tolerances.

Sustainability in LDPE film production focuses on energy efficiency, use of recycled content, and exploring biodegradable or compostable alternatives where feasible. Energy-saving measures include selecting energy-efficient drives, optimized screw profiles to lower specific energy consumption, and process controls that reduce heating/cooling cycles. Processing recycled LDPE requires compatible line designs with robust filtration, melt homogenization, and potential layer strategies that use recycled material in core layers while preserving virgin surfaces. Below are targeted strategies for integrating sustainability into blown film operations.

These strategies reduce the environmental footprint while maintaining product quality; the next H3s unpack energy and recycled-material measures and the prospects for biodegradable LDPE alternatives.

Energy efficiency gains come from optimized screw geometry that reduces shear heating, efficient electric drives, and precise process controls that minimize thermal cycling; measurable metrics include specific energy consumption (kWh/kg) which influences operating cost and sustainability reporting. For recycled LDPE, robust pelletizing, consistent feedstock specification, and layer engineering allow high recycled content in the core while maintaining virgin-like outer layers for optical and sealing properties. Quality control is essential when using recycled feedstock—regular melt-flow monitoring, contaminant screening, and tightened inspection protocols prevent defects and protect downstream converters.

Developing biodegradable or compostable LDPE alternatives requires formulation changes and careful machine validation; additive packages and polymer blends can alter melt rheology, requiring screw and die adjustments and sometimes retrofits to feeding and mixing systems. While machine-level adaptations can enable production of bio-enhanced films, trade-offs in clarity, sealability, and mechanical strength must be managed through testing and pilot runs. Producers should adopt incremental validation protocols and partner with materials specialists to ensure that biodegradable formulations meet application and regulatory expectations without compromising line reliability.

For producers ready to move from evaluation to procurement, established equipment suppliers can offer tailored lines and commissioning support; select manufacturers that demonstrate clear QA, warranty, and after-sales capabilities aligned with sustainability goals. Kingdom Machine Co., Ltd. is a manufacturer and supplier that specializes in plastic film and bag production equipment and offers configurable blown film machines for LDPE/LLDPE, multi-layer and ABA lines, and complementary recycling and converting equipment. Their published capabilities emphasize simple operation, easy maintenance, timely after-sales service, and customization options, and they position themselves as a one-stop provider for customized product and service needs.

For inquiries about customized LDPE blown film lines, warranty terms, or to schedule a demonstration, contact Kingdom Machine Co., Ltd. and request their product catalogue or contact page for detailed specifications and quote options.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;