Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

High-Density Polyethylene (HDPE) blown film machines play a crucial role in the production of various plastic films used across multiple industries. This comprehensive guide will delve into the intricacies of HDPE blown film machines, their operational mechanisms, and their applications in the market. Readers will gain insights into how these machines function, the different types available, and the technical specifications that set them apart. As industries increasingly seek efficient and sustainable solutions, understanding the capabilities of HDPE blown film machines becomes essential. This article will cover the operational processes, types of machines, technical innovations, applications, material properties, and market trends, providing a well-rounded perspective on this vital equipment.

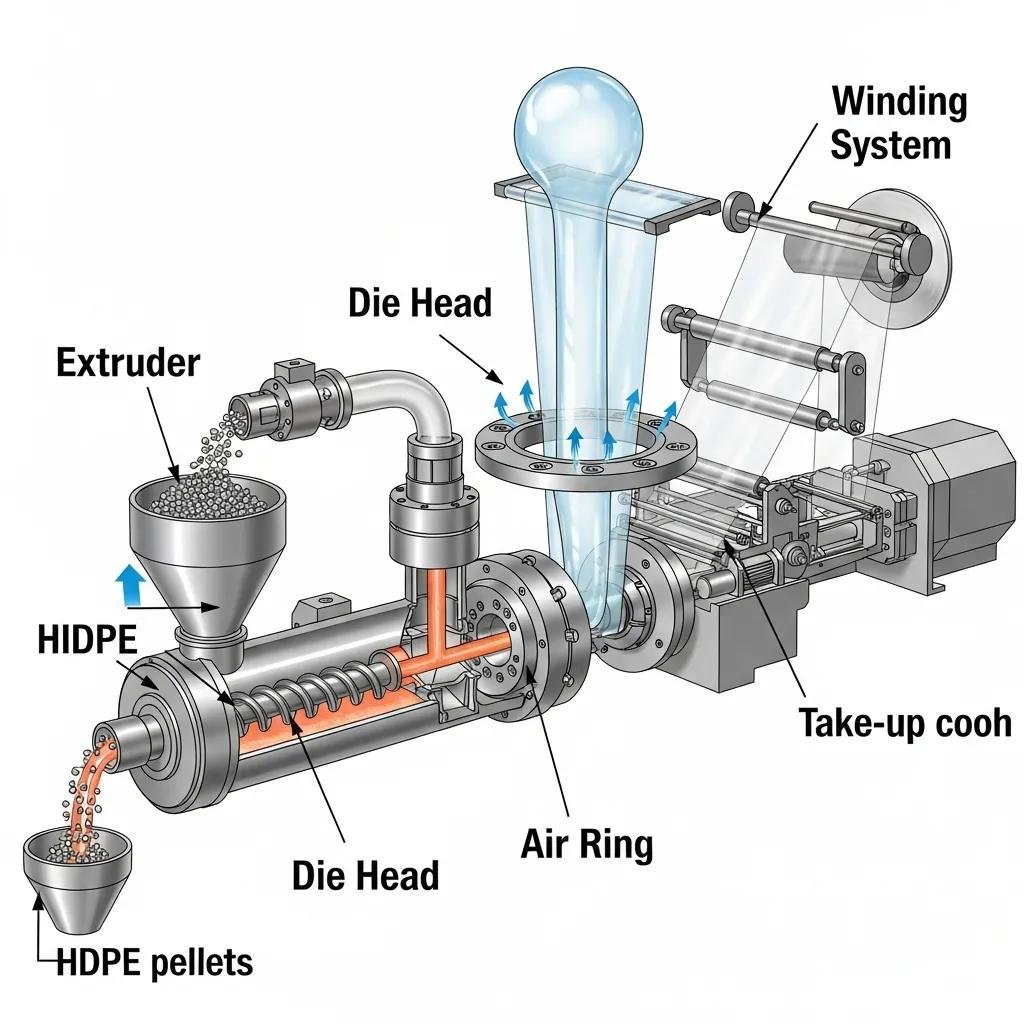

HDPE blown film machines are specialized equipment designed to produce thin plastic films from high-density polyethylene. These machines utilize a blown film extrusion process, where plastic pellets are melted and formed into a continuous tube of film. The process involves several key steps, including melting the polymer, extruding it through a die, and inflating it to achieve the desired thickness and width. The significance of these machines lies in their ability to create films that are lightweight, durable, and versatile, making them suitable for various applications in packaging and industrial sectors.

The blown film extrusion process begins with the feeding of HDPE pellets into the extruder, where they are heated and melted. The molten polymer is then forced through a circular die, forming a thin tube. As the tube exits the die, it is inflated with air, expanding it to the desired diameter. This inflation process is crucial as it determines the film’s thickness and properties. Once the film reaches the desired dimensions, it is cooled and wound onto rolls for further processing. This method allows for the efficient production of high-quality HDPE films that meet industry standards.

HDPE blown film machines consist of several critical components that work together to ensure efficient film production. The main components include:

Understanding these components is essential for optimizing the performance and output of HDPE blown film machines.

There are various types and models of HDPE blown film machines, each designed to cater to specific production needs. These machines can be categorized based on their configuration and capabilities.

High-speed and compact HDPE film extrusion lines are designed to maximize production efficiency. High-speed lines can significantly increase output, reducing production time and costs. Compact designs save floor space and are easier to integrate into existing production facilities. These advancements allow manufacturers to meet growing market demands while maintaining high-quality standards.

Understanding the technical specifications of HDPE blown film machines is crucial for selecting the right equipment for specific applications. Key specifications include the machine’s output capacity, film thickness range, and the types of materials it can process.

The design of the screw and barrel in an extruder plays a vital role in determining the quality of the produced film. A well-designed screw ensures efficient melting and mixing of the polymer, leading to uniform film properties. Variations in screw geometry can also influence the output rate, with specific designs optimized for different types of HDPE formulations.

The die head, air ring, and winding systems are integral to the blown film process. The die head shapes the film, while the air ring cools it, ensuring that the film maintains its desired thickness and properties. The winding system collects the finished film, allowing for easy handling and storage. Each component must work in harmony to produce high-quality HDPE films efficiently.

HDPE films produced by blown film machines have a wide range of applications across various industries. Their versatility and durability make them suitable for numerous uses.

HDPE films are commonly used in the production of plastic bags and flexible packaging materials. Their strength and resistance to moisture make them ideal for grocery bags, trash bags, and food packaging. The lightweight nature of HDPE films also contributes to reduced shipping costs and environmental impact.

In agriculture, HDPE films are utilized for greenhouse covers, mulch films, and silage bags, providing protection and enhancing crop yields. In industrial applications, these films are used for protective wraps, pallet covers, and various packaging solutions, demonstrating their adaptability and effectiveness in diverse settings.

The material properties of HDPE significantly influence the production process and the quality of the final product. Additionally, sustainability considerations are becoming increasingly important in the manufacturing of HDPE films.

HDPE, LDPE (Low-Density Polyethylene), and LLDPE (Linear Low-Density Polyethylene) are three types of polyethylene used in film extrusion. HDPE is known for its strength and rigidity, making it suitable for heavy-duty applications. LDPE is more flexible and transparent, often used for lightweight packaging. LLDPE combines the properties of both, offering enhanced stretchability and strength, making it ideal for various applications.

Recycled HDPE can be used in film production, contributing to sustainability efforts by reducing waste and conserving resources. Additives such as UV stabilizers and anti-block agents can enhance the performance of HDPE films, improving their durability and functionality. However, the use of recycled materials may require adjustments in processing conditions to maintain film quality.

When investing in HDPE blown film machines, buyers should consider the support and services offered by manufacturers, as well as current market trends.

Kingdom Machine Co., Ltd. emphasizes quality assurance through rigorous testing and a 100 percent final inspection of all machines. They offer a two-year warranty on timer switches, ensuring reliability and peace of mind for customers. Additionally, their after-sales service includes maintenance support, helping clients optimize machine performance and longevity.

The market for HDPE films is projected to grow steadily, driven by increasing demand for sustainable packaging solutions and advancements in film production technology. Trends such as the adoption of multi-layer co-extrusion processes and the use of recycled materials are shaping the future of HDPE film production, making it essential for manufacturers to stay informed and adapt to these changes.

| Machine Type | Key Features | Applications |

|---|---|---|

| Monolayer HDPE Blown Film Machines | Cost-effective, simple design | Basic packaging |

| Tandem (Twin) HDPE Extruders | Co-extrusion capability for multiple layers | Enhanced efficiency and film properties |

| Multi-Layer HDPE Co-Extrusion Lines | Multiple material layers | High-performance packaging |

HDPE blown film machines are essential for producing high-quality films used in various applications. Understanding their operation, types, and technical specifications allows manufacturers to make informed decisions when investing in this equipment. As the market continues to evolve, staying updated on trends and innovations will be crucial for success in the industry.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;