Reliable Spare Parts and Components for Your Machines

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Cast stretch film machines are specialized film extrusion systems that convert LLDPE resin into thin, high-clarity stretch film using a flat die and chill roll cooling to lock in optical and mechanical properties. These machines deliver clear packaging film with high tensile strength and controlled cling, enabling efficient pallet wrapping, retail packaging, and industrial bundling while optimizing throughput and material yield. This article explains the cast film extrusion process, contrasts multi-layer co-extrusion benefits, and details how automation, precision thickness control, and energy-efficient components reduce waste and improve ROI. Readers will learn how to interpret technical specifications (kg/hr, width, thickness tolerances), choose layer configurations for specific applications, and evaluate automation features that raise consistent quality. Along the way, practical tables and lists compare 3-, 5-, and 7-layer options, automation gains, and machine model attributes to support equipment selection. Finally, we outline how a manufacturing partner positions one-stop customization, rigorous QA, and production capacity to support fast delivery and scalable supply.

A cast stretch film machine is a film extrusion line that uses melt extrusion through a flat die followed by rapid cooling on a chilled roll to produce oriented, high-clarity LLDPE stretch film. The mechanism relies on rapid quenching on the chill roll to suppress crystallinity and achieve optical clarity while dimensional stabilization and winding complete the process for consistent roll quality. Cast film methods yield quieter unwind, better clarity, and finer thickness control than some alternatives because cooling and laydown are tightly controlled at the nip. Understanding this process is essential for specifying film properties such as cling, puncture resistance, and tensile strength for packaging applications. The next subsection breaks the cast extrusion process down into practical steps and material considerations to guide production decisions.

The cast extrusion process for LLDPE begins with precise resin feed, melting in the extruder, and homogenization in the screw and barrel to ensure consistent melt viscosity and additive dispersion. Molten LLDPE is forced through a flat die to create a thin film sheet that immediately contacts a driven chill roll where rapid quenching reduces crystallinity and enhances clarity; chill roll temperature and surface finish directly affect optical quality. Post-chill, air knives or guiding systems control bubble-free laydown before the film reaches an automatic winding system that sets winding tension and roll diameter. Process control for screw speed, die gap, and chill roll temperature are key levers to tune film cling and puncture resistance, and this understanding leads into the roles of core machine components that follow.

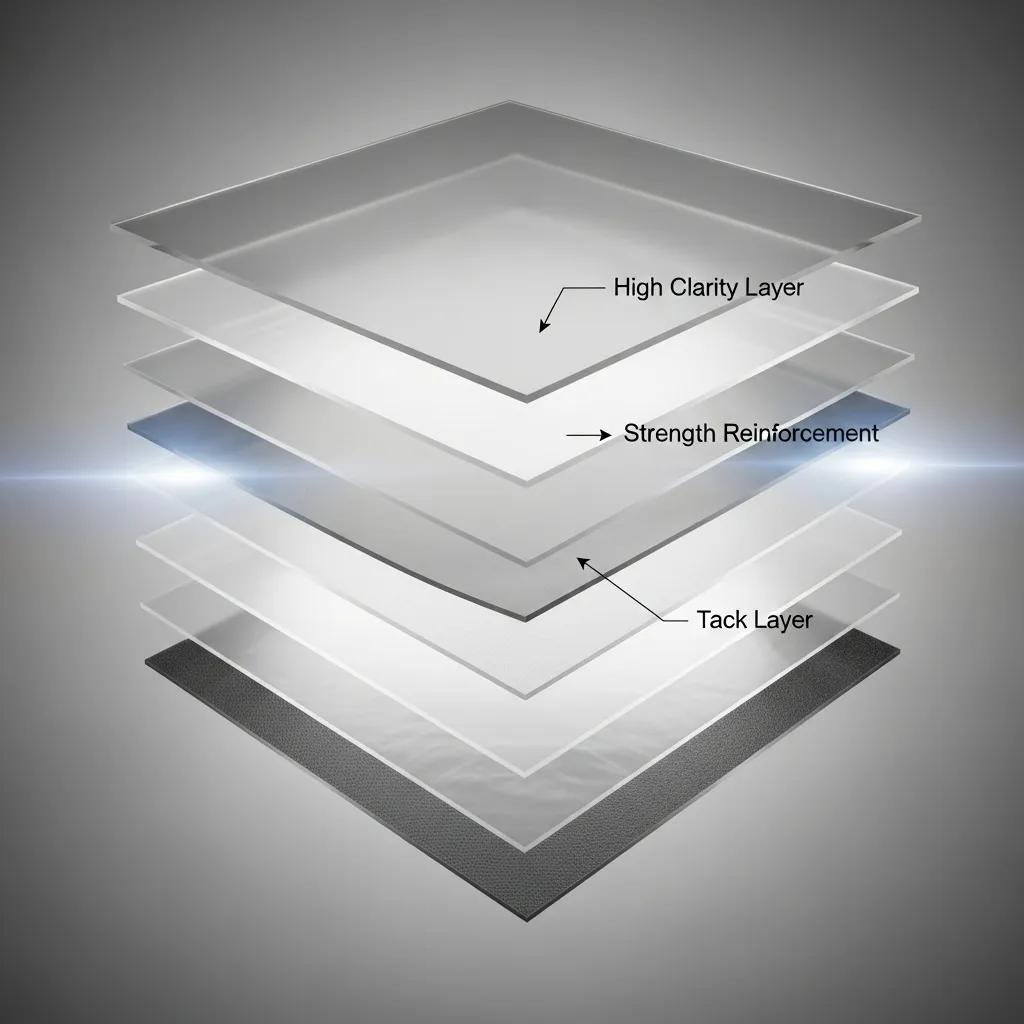

Critical meronyms of a cast stretch film machine include the extruder (screw and barrel), flat die, chill roll, thickness gauge/online sensor, and an automatic winder with tension control; each element directly influences film uniformity and end-use performance. The extruder provides melt homogeneity—screw geometry and L/D ratio affect residence time and dispersion—while the flat die defines film thickness profile across the web. Chill rolls enable rapid cooling and orientation control, and surface finish plus temperature stability determine clarity and gloss. Automatic winding systems manage roll build, tension control, and automatic roll change to prevent defects and maintain consistent roll weight, and these system components set the stage for multi-layer co-extrusion benefits discussed next.

Multi-layer cast stretch film machines use co-extrusion to combine distinct polymer layers, producing films that balance clarity, strength, and puncture resistance while enabling functional layer customization for cling, slip, or barrier properties. Layered construction lets manufacturers place specific materials where they matter most—outer layers for clarity and printability, core layers for puncture resistance and load-holding strength—so multi-layer designs improve performance without wholesale material cost increases. Multi-layer approaches also enable thin high-performance core layers using mLLDPE blends to enhance toughness while keeping surface layers optimized for clarity and cling. The following table compares common multi-layer configurations to guide selection, and the summary that follows links these benefits to supplier capabilities for custom development and rapid prototyping.

Multi-layer cast stretch film offers distinct advantages:

These benefits make multi-layer films suitable across logistics and retail packaging categories, and choosing the right layer count depends on the trade-off between cost and enhanced mechanical or optical properties. Below is a comparison table that maps common layer counts to practical impacts.

| Layer Configuration | Key Benefit | Practical Impact |

|---|---|---|

| 3-Layer | Cost-effective clarity and strength | Suitable for standard pallet wrap and general retail packaging where moderate puncture resistance suffices |

| 5-Layer | Balanced clarity, cling, and puncture resistance | Ideal for mixed-load logistics and food packaging requiring better load stability and visual inspection |

| 7-Layer | High-performance toughness with tailored surfaces | Best for heavy-duty industrial bundling and applications needing maximum puncture resistance and controlled cling |

This table clarifies the trade-offs between cost and performance and informs specification decisions; next we show how real-world suppliers can support layer customization and rapid delivery for production needs.

Kingdom Machine Co., Ltd. (also known as China Evergreen Machinery Co., Ltd.) supplies multi-layer cast stretch film machines and co-extrusion lines that support 3-, 5-, and 7-layer configurations and offer customization in logos, labels, and packaging to match application requirements. The company positions one-stop service and new product development capabilities to translate film performance requirements into machine configurations and prototyping. For teams seeking quotes or specifications, Kingdom Machine emphasizes fast sample turnaround and customization options that align with the multilayer benefits just discussed.

Automation in stretch film production lines—PLC control, inline thickness gauges, automatic roll change, and tension control—improves consistency, reduces scrap, and raises effective throughput by lowering manual intervention and process variability. Automated thickness control and online sensors maintain tight tolerances across long runs, reducing off-spec film that leads to rework or waste, while automatic roll change and tension regulation minimize downtime and operator requirements. Automation also enables data-driven monitoring of KPIs like yield, scrap rate, and uptime, so managers can quantify process improvements and target continuous optimization. The short numbered list below outlines typical automation benefits with measurable impacts and leads into a table that maps automation features to operational metrics for decision-makers.

Automation delivers clear operational gains:

Automation features translate into quantifiable improvements that justify capital investment, and the following table links specific automation features to expected operational outcomes and typical improvement ranges.

| Automation Feature | Operational Metric Impact | Typical Improvement |

|---|---|---|

| Inline thickness gauge | Thickness variance | 40–70% reduction |

| PLC process control | First-pass yield | 15–30% improvement |

| Automatic roll change | Downtime per shift | 30–60% reduction |

| Tension control system | Roll quality consistency | Significant reduction in roll defects |

This mapping helps purchasing teams prioritize automation modules based on targeted metrics; the next subsection describes the control and sensor features that produce these outcomes.

Automatic production lines integrate sensors, servo drives, and PLC logic to maintain uniform film thickness, stable winding tension, and consistent output across shifts and operators. Inline thickness gauges provide real-time feedback to the die gap and extrusion load, enabling closed-loop control that reduces thickness variance and stabilizes gauge across web width. Tension control systems and automatic roll change units preserve roll build quality and prevent telescoping, while integrated HMI/SCADA systems capture process data for traceability and preventative maintenance. These combined features create a predictable production environment where film optical properties and mechanical strength remain within specification, and the final sentence introduces the quantifiable labor and material savings achieved through automation.

Advanced control systems shift operator tasks from manual adjustment to supervision and exception handling, enabling a single operator to manage more lines and reducing headcount pressures during peak production. Precise extrusion dosing, better melt homogeneity, and accurate thickness control decrease start-up scrap and trim waste, which directly lowers resin consumption and cost per roll. Industry benchmarking shows that automation can reduce material scrap and rework by significant percentages, while improving overall line OEE through fewer stops and faster roll changes. These operational gains support ROI calculations for automation investments and connect to technical specification choices discussed next.

Key technical specifications for LLDPE stretch film machines include production capacity (kg/hr), film width range, thickness range, number of layers, screw diameters, and installed power; interpreting these specs lets buyers match equipment to target monthly throughput and roll formats. Production capacity maps to finished roll counts per shift when accounting for film basis weight, roll diameter, and winding efficiency, while film width and thickness ranges determine which market segments can be served. Energy consumption and precision thickness control specifications indicate operating cost and scrap risk; features like variable-frequency drives and servo motors reduce energy draw and improve responsiveness. The table below provides a model-style EAV comparison to help choose a machine class, and a short explanation follows showing how to convert kg/hr into daily or monthly outputs.

Selecting the right spec requires balancing capacity needs with film thickness and width flexibility; the following table gives representative model classes and attribute ranges for quick decision-making.

| Model Class | Production Capacity (kg/hr) | Film Width Range (mm) | Thickness Range (µm) | Power Consumption (kW) | Layers |

|---|---|---|---|---|---|

| Compact L | 50 – 120 | 200 – 600 | 8 – 20 | 30 – 45 | 3 – 5 |

| Standard M | 120 – 300 | 300 – 1000 | 8 – 30 | 45 – 90 | 3 – 7 |

| High-Capacity H | 300 – 700 | 500 – 1600 | 10 – 40 | 90 – 200 | 5 – 7 |

This model-class overview helps teams estimate throughput and floor-space needs; next we explain how to convert kg/hr to finished roll output for planning.

Converting production capacity into finished rolls starts by calculating grams per square meter for the specified thickness and width then multiplying by roll area; for example, a 200 mm wide web at 20 µm corresponds to a certain grams per meter that can be scaled to kg/hr to estimate meters per hour and rolls per shift. Film width and thickness ranges determine produced roll formats—narrow widths for retail packaging and wider webs for pallet wrap—so specifying both ranges ensures compatibility with downstream converting equipment. Screw diameter and extruder L/D influence maximum throughput and melt homogenization, which affect the upper capacity bound. Understanding these relationships enables production planners to select a machine class that delivers required monthly output with acceptable energy and operator costs.

Kingdom Machine provides machine classes and customizable configurations across these capacity ranges and supports one-stop customization for layer counts and package printing; they note availability for sample orders and standard bulk delivery timelines to assist buyers with planning. Model-specific quotes and specifications can be requested to align production capacity with facility targets.

Energy efficiency in stretch film machines derives from variable-frequency drives (VFDs), energy-efficient motors, and process optimization that reduces idle running and thermal losses; these features typically produce double-digit percent reductions in electrical consumption versus legacy drives. Precision thickness control combines online sensors, feedback to die gap or screw speed, and fast-acting actuators to maintain tolerances often within a few percent of target thickness, lowering material cost and improving first-pass yield. Integrating energy-saving drives with thickness control yields operational cost savings and more predictable production, and these technologies are now standard expectations for high-speed stretch film production lines. With this technical foundation, application mapping clarifies which industries benefit most from cast stretch films.

Clear and strong cast stretch film serves logistics, food and beverage, agriculture, medical supplies, and retail packaging by combining optical clarity with load stability, puncture resistance, and tailored cling properties. Logistics and pallet wrapping prioritize puncture resistance and load-holding to prevent damage during transit, while food and beverage packaging needs optical clarity and safe film formulations for retail presentation. Agriculture and medical industries emphasize material cleanliness, recyclable options, and controlled cling to protect sensitive products. The list below highlights primary industries and the film attributes they typically require, followed by a short summary to connect industry needs to specification choices.

Primary beneficiary industries include:

Matching film specifications—layer count, thickness, and cling level—to these industry demands reduces returns and improves customer satisfaction. The next subsection provides selection tips for common applications in these sectors.

In pallet wrapping, cast stretch film must stabilize loads, resist puncture from corners, and maintain tension during handling; a 5-layer construction with a tough core and cling-optimized outer layers is often recommended. Food packaging emphasizes clarity and low haze to ensure product visibility, so surface layers formulated for optical quality and neutral odor are prioritized while keeping thickness minimal for cost efficiency. Industrial bundling may require thicker films with higher puncture resistance and reinforced cores to protect heavy or sharp items. Selection tips include choosing higher layer counts for heavy-duty loads and prioritizing precision thickness control when tight tolerances impact downstream converting equipment. These application-specific considerations lead naturally into sustainable options for sensitive industries.

Sustainability considerations for agriculture and medical packaging include recyclable LLDPE blends, integration with recycling equipment, and lines designed to minimize energy and material waste during production. Modern cast lines can reduce scrap through tighter thickness control and faster setup times, lowering per-roll environmental footprint, while recycling machines and on-site material reclamation loops support circular workflows. For medical packaging, material traceability and low-emission extrusion practices help meet regulatory and buyer expectations for cleanliness and sustainability. Emphasizing energy-efficient motors and process optimization reduces operational emissions and supports long-term cost savings, setting the stage for supplier service commitments discussed next.

Kingdom Machine Co., Ltd. (also known as China Evergreen Machinery Co., Ltd.) blends manufacturing scale, R&D resources, and service commitments to support customers seeking high-quality cast stretch film equipment with customization and reliable delivery. The company highlights 100% final inspection and a targeted 1–3% defective control rate, backed by an R&D lab with over 30 testing devices and 16 production lines that enable development and verification of machine configurations. Warranty terms and component guarantees include a two-year warranty on timer switches, reflecting focused component-level assurances. These quality and testing commitments help buyers reduce commissioning risk and accelerate time-to-production.

Quality assurance at Kingdom Machine includes complete final inspection procedures and defect control targets that aim to minimize out-of-the-box issues for commissioning teams, which supports smoother production ramp-up. The company’s R&D team and lab capacity enable iterative testing across formulations and layer structures, allowing one-stop customization for logos, labels, packaging, and new product development to ensure the machine matches the intended film performance. Large-scale production capacity and multiple assembly lines contribute to competitive pricing through economies of scale while maintaining production flexibility. These combined capabilities create a practical pathway from specification to delivered equipment that meets technical requirements.

Service commitments emphasize fast delivery and responsive support: sample orders are typically available within three days, standard bulk orders ship within 15–20 days, and customized projects are scheduled within 30–60 days, enabling buyers to plan supply ramp-up with predictable timelines. After-sales support focuses on customer-centric assistance, including parts and maintenance guidance, while environmental responsibility is addressed through energy-saving design choices and the availability of recycling machines to close material loops. For procurement teams evaluating suppliers, these operational and sustainability commitments provide measurable benefits in lead time, lifecycle cost, and environmental impact.

Selecting a supplier with demonstrable QA, R&D depth, and delivery transparency helps align equipment acquisition with production and sustainability goals.

Elevate your machinery performance with our premium spare parts and components. Trust in our quality and reliability for optimal operation and longevity.

Maximize efficiency with expert installation for your plastic production machines. Our professional team ensures optimal performance tailored to your needs.

Transform your concepts into reality with our tailored installation solutions. Experience professional guidance and exceptional results designed just for you.

Elevate your production with essential tips for selecting the right plastic bag making equipment. Make informed choices for efficiency and quality today.

China Evergreen Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.

Whatsapp:0086-13088651008;